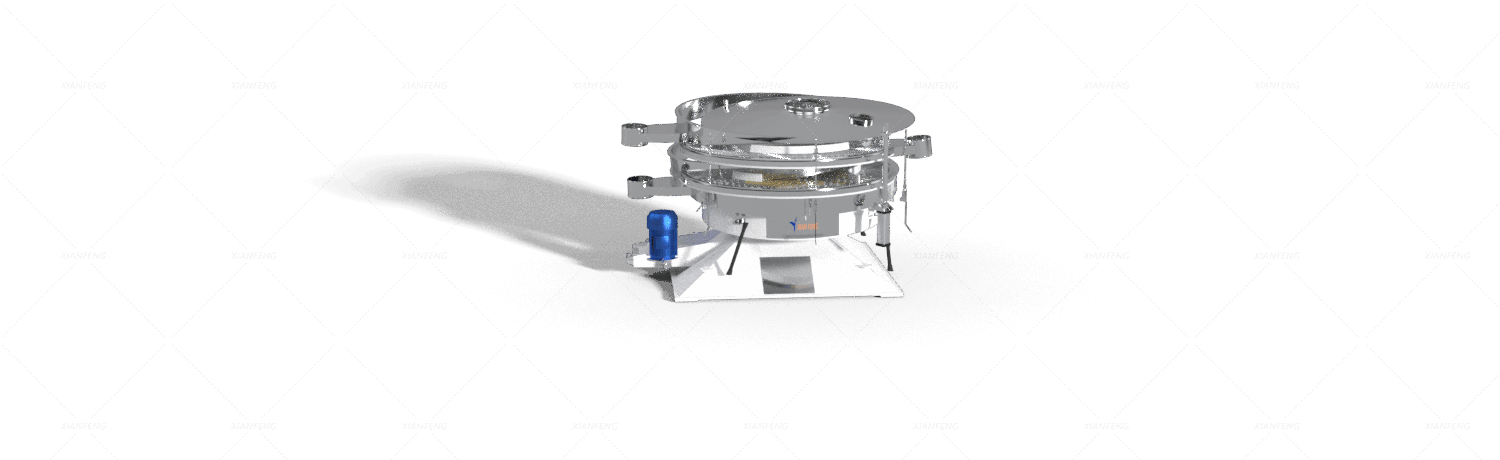

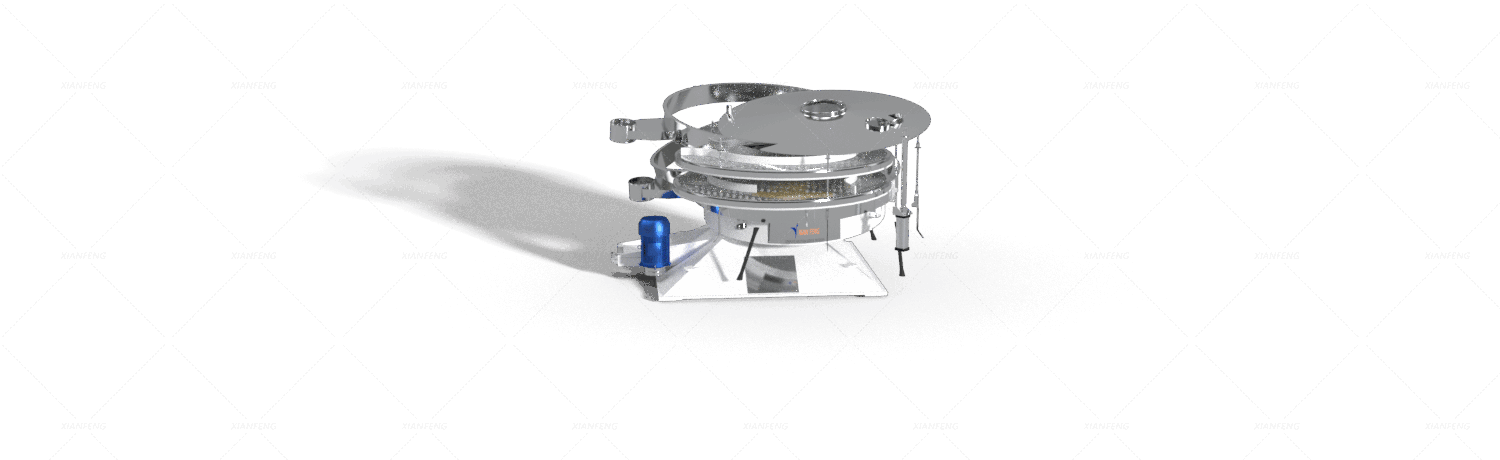

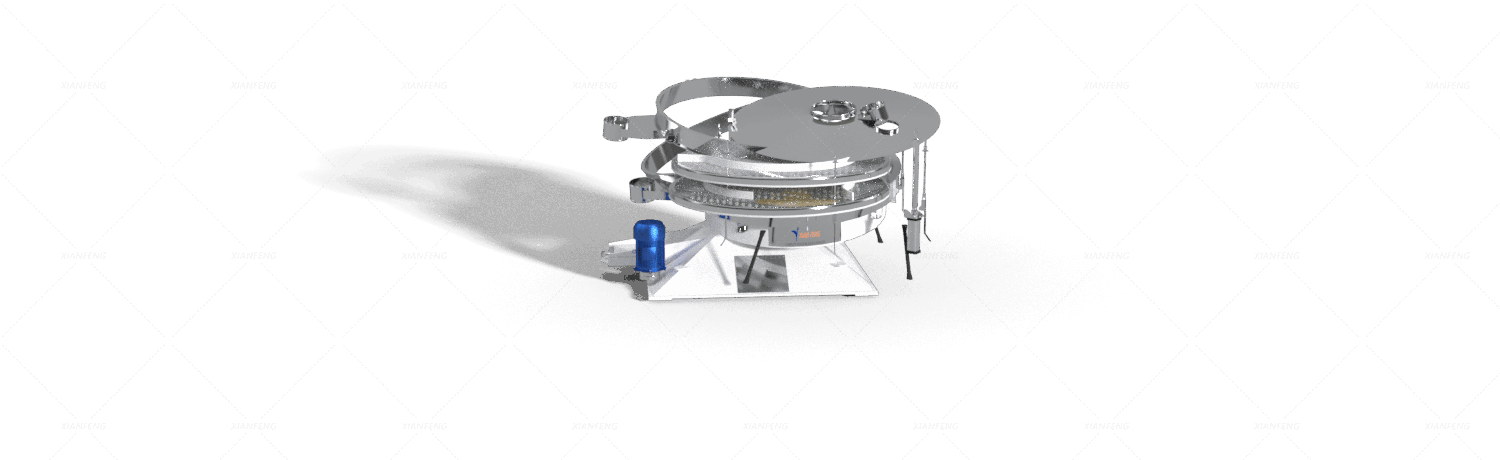

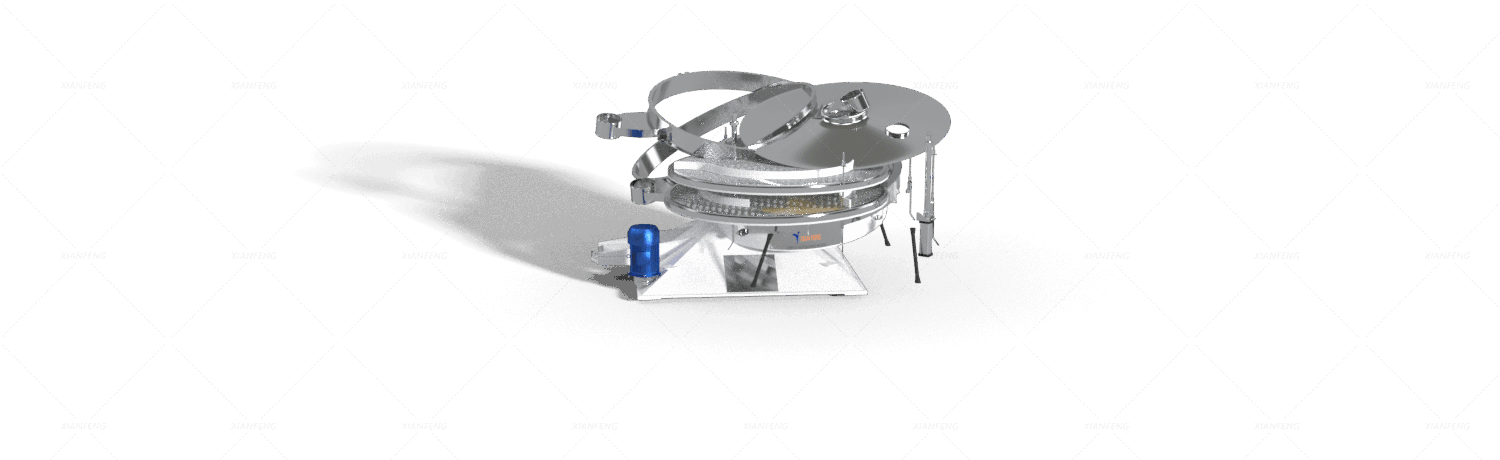

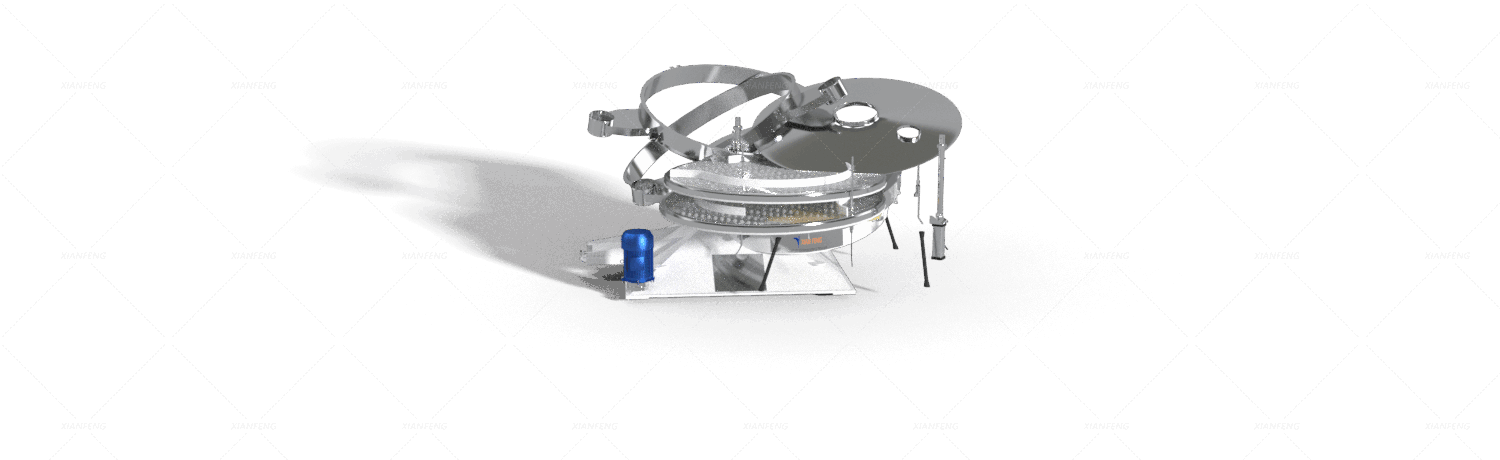

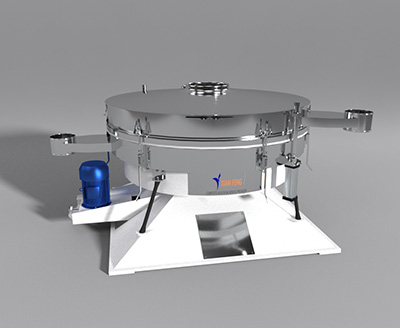

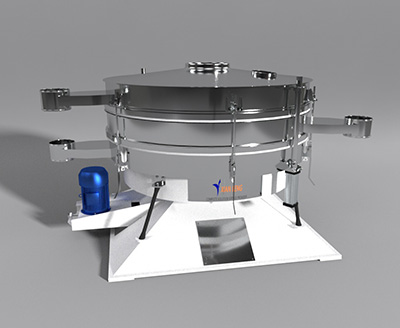

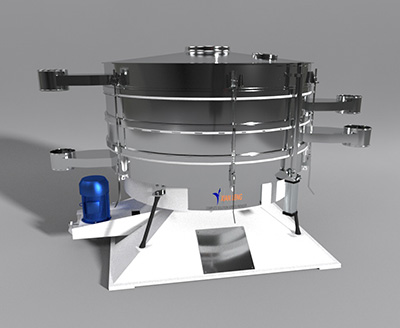

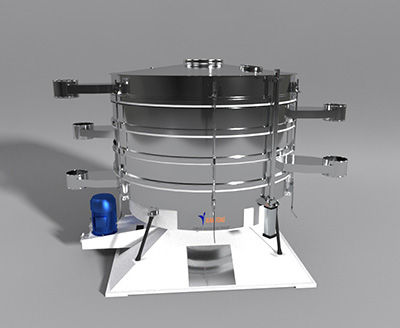

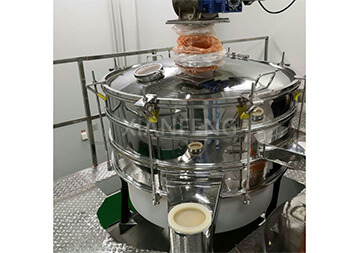

Tumbler Screener is a high-efficiency screening machine specifically developed for the screening requirements of dry bulk fine and ultra-fine materials. Featuring high precision and high capacity, it is widely applicable in industries such as food, chemical, pharmaceutical, mining, and new materials.The rotational motion of the circular rotating screen causes the material to roll on the surface of the screen. This achieves efficient size classification while minimizing material breakage and protecting product integrity. It is the preferred equipment for screening dry powders or granules and for dust removal.

Flour, starch, white sugar, powdered sugar, glucose powder, salt, pepper, chili powder, seeds, etc.

Traditional Chinese medicine powder, Western medicine powder, pharmaceutical tablets, pharmaceutical capsules, pharmaceutical intermediates, etc.

PVC resin powder, polypropylene granules, epoxy resin, titanium dioxide, pigments, catalysts, additives, etc.

Quartz sand, iron ore powder, quartz sand, limestone, kaolin, cement clinker, silica fume, foundry sand, etc.

Aluminum powder, lead powder, electrolytic copper powder, masterbatch, NdFeB magnetic powder, amino acid granules, etc.

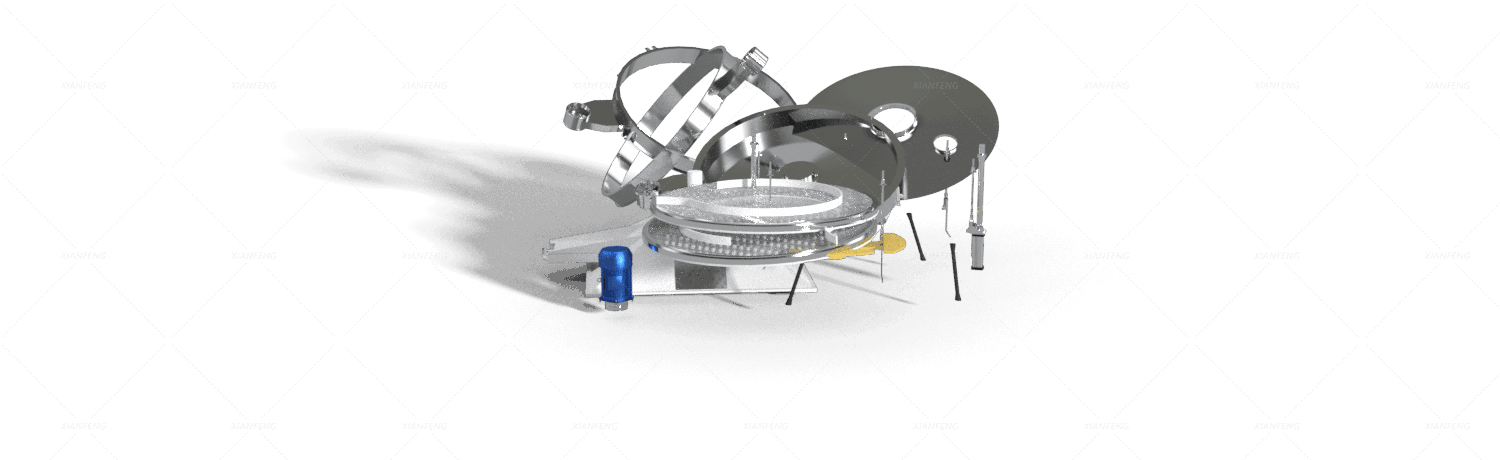

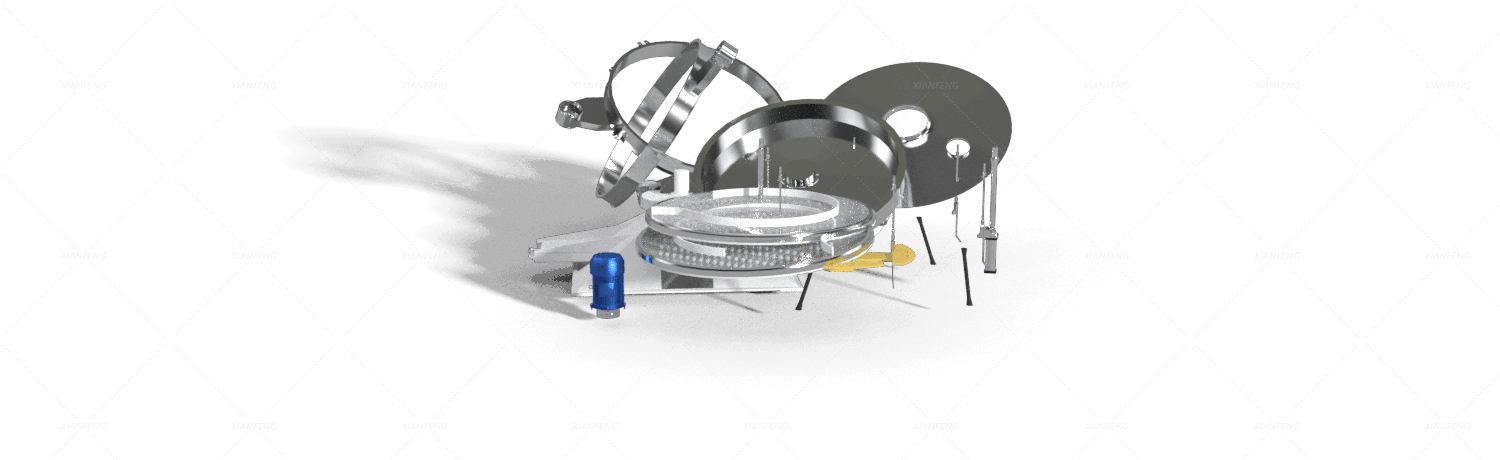

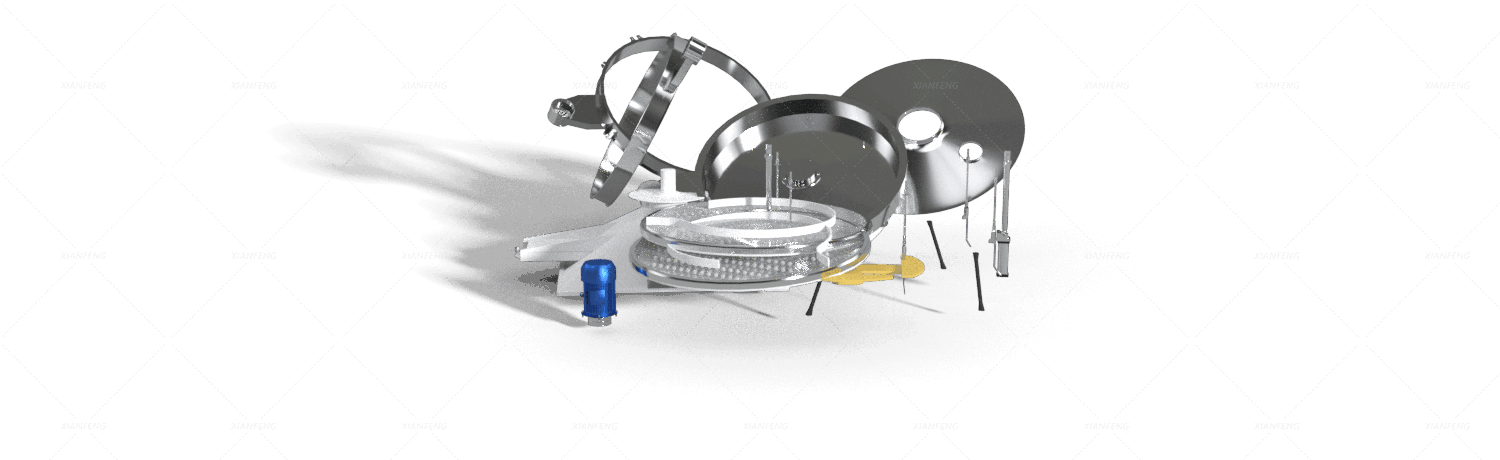

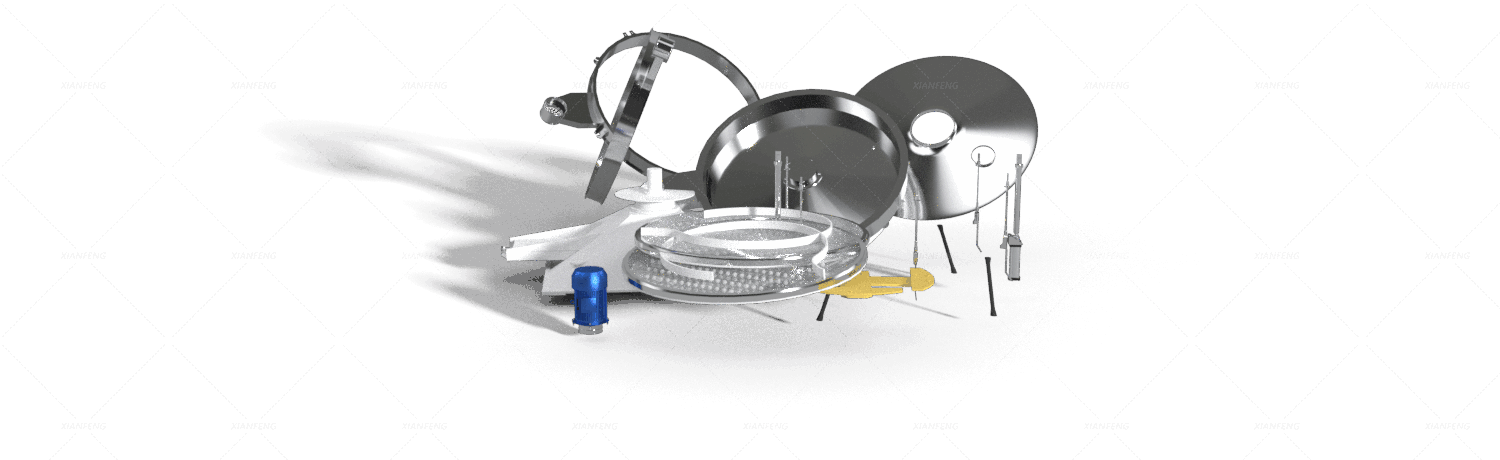

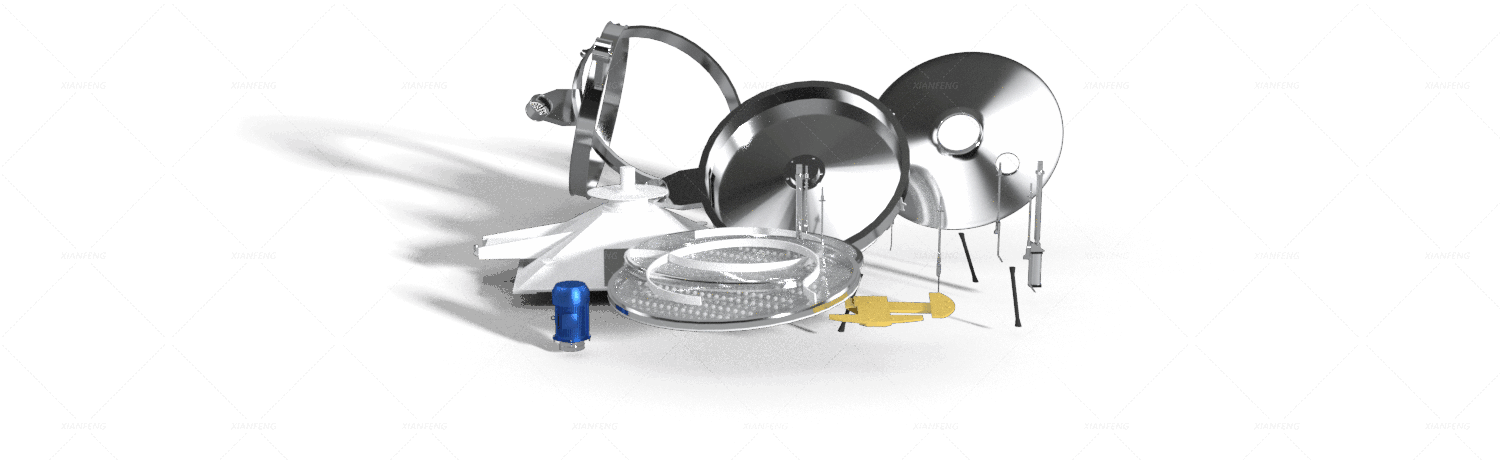

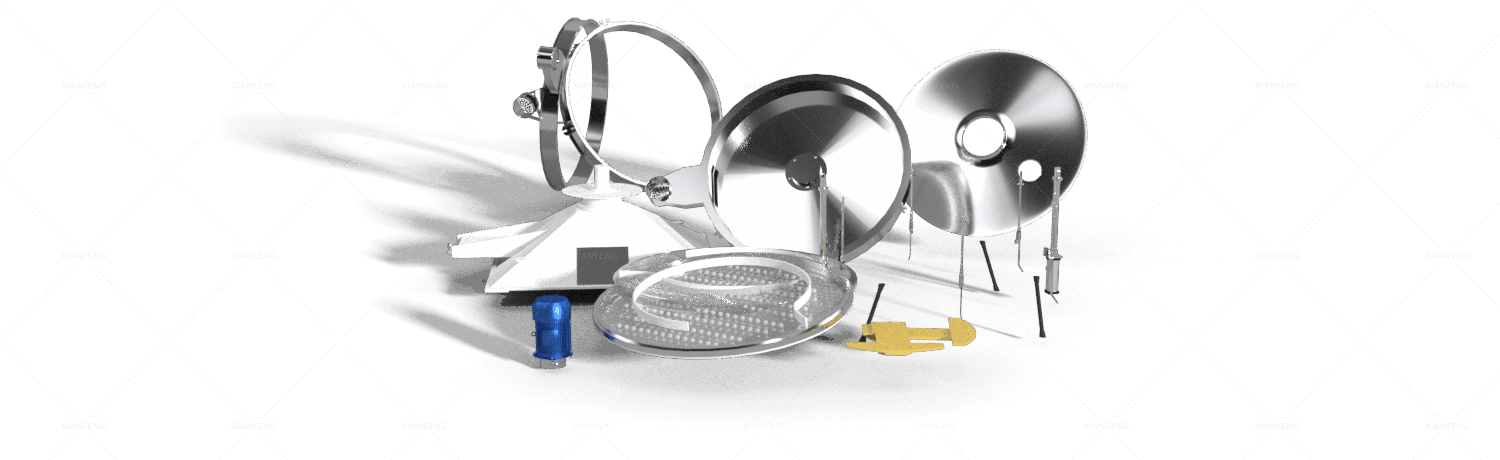

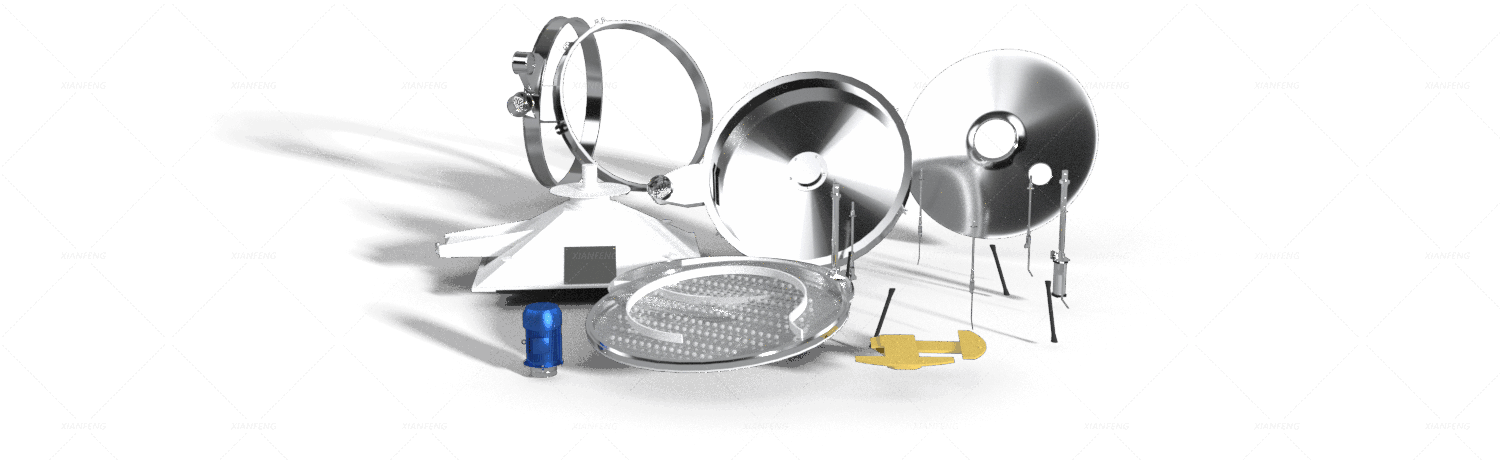

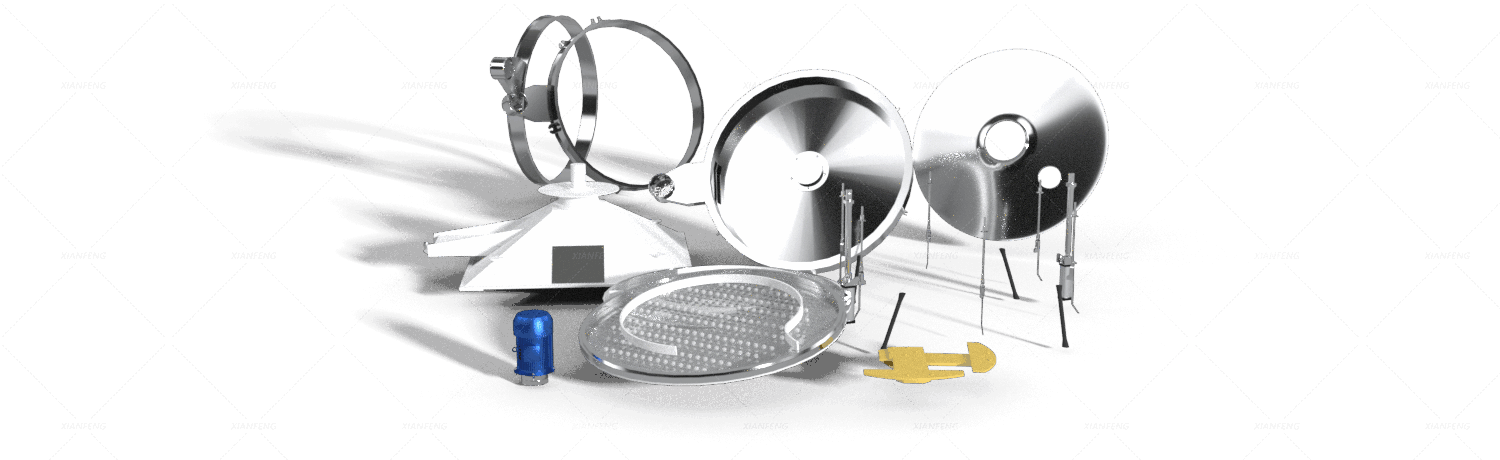

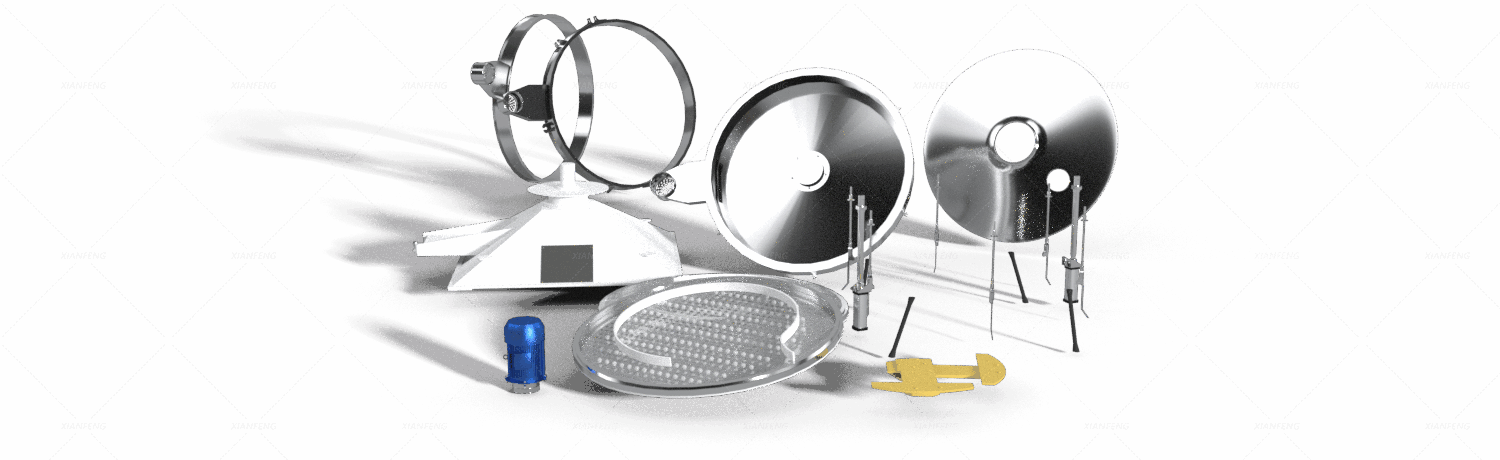

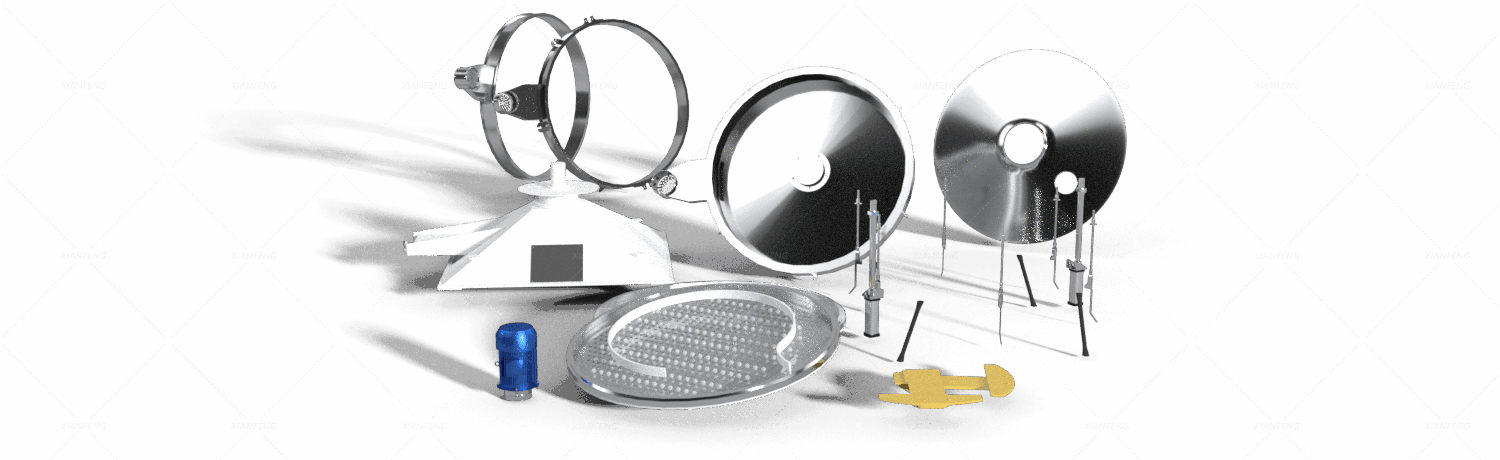

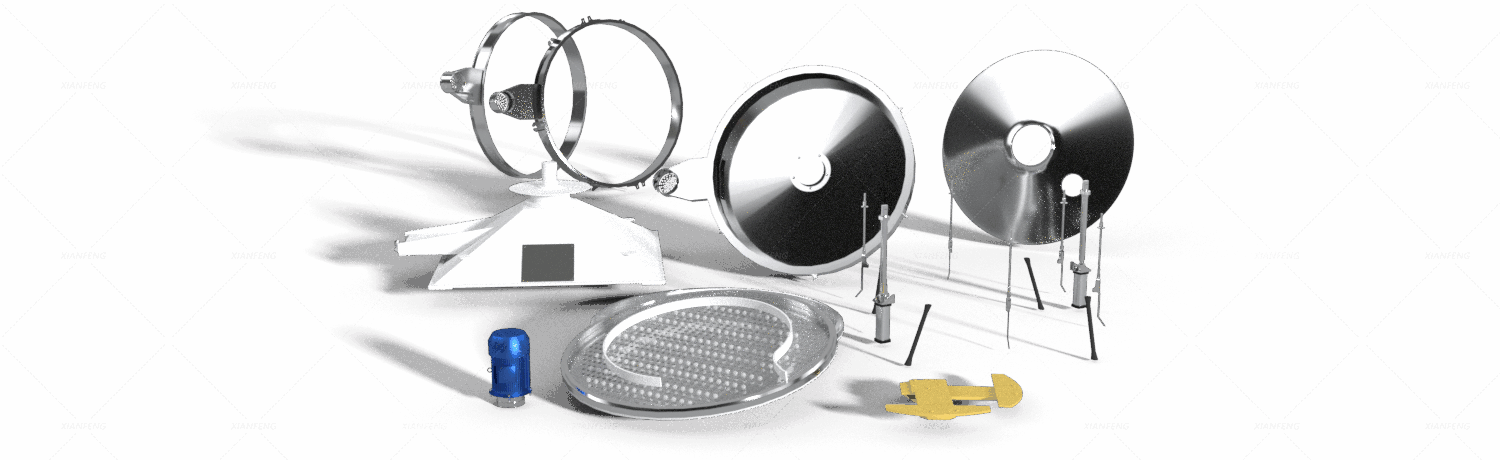

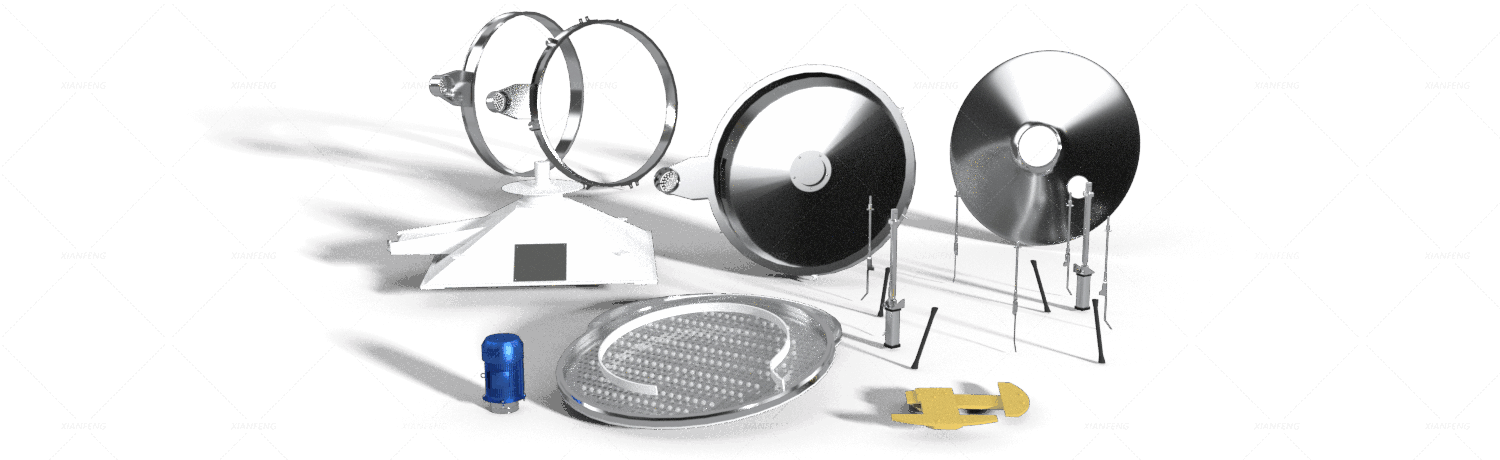

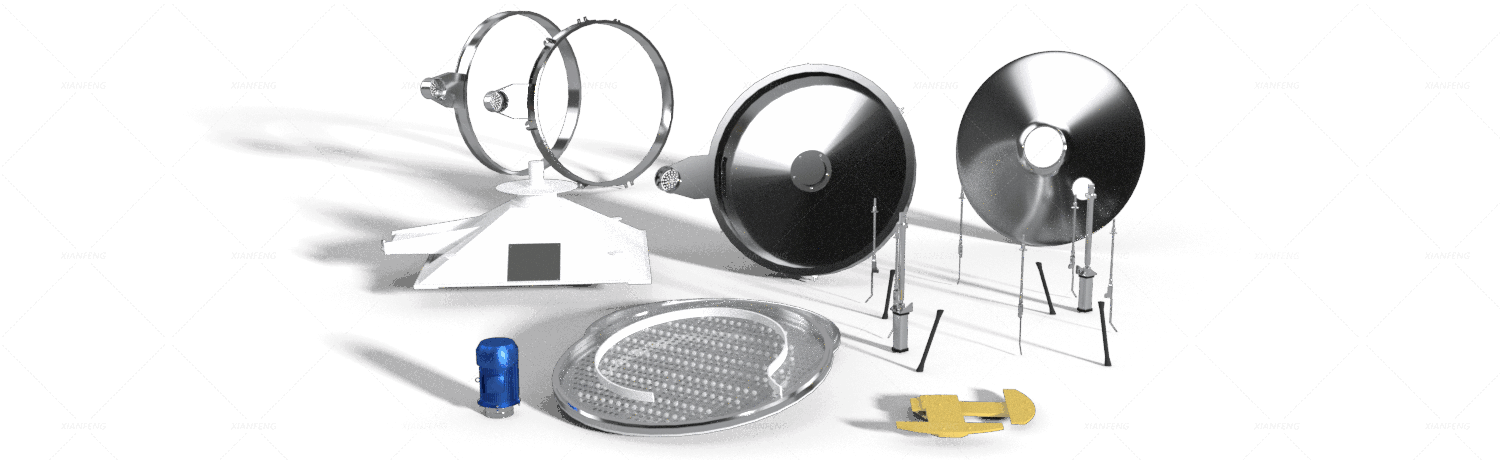

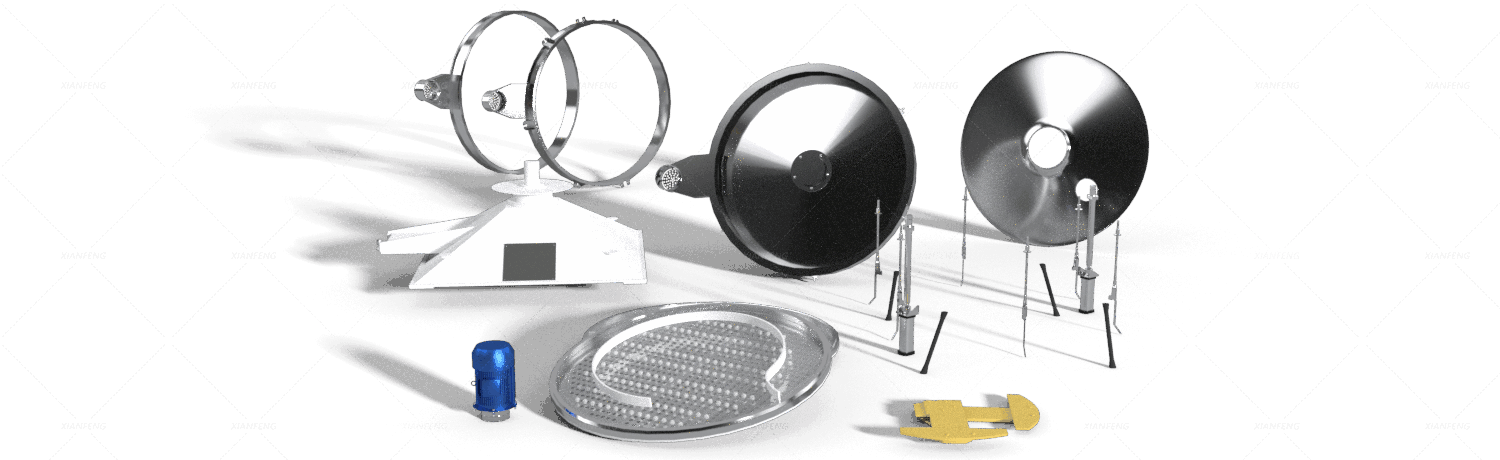

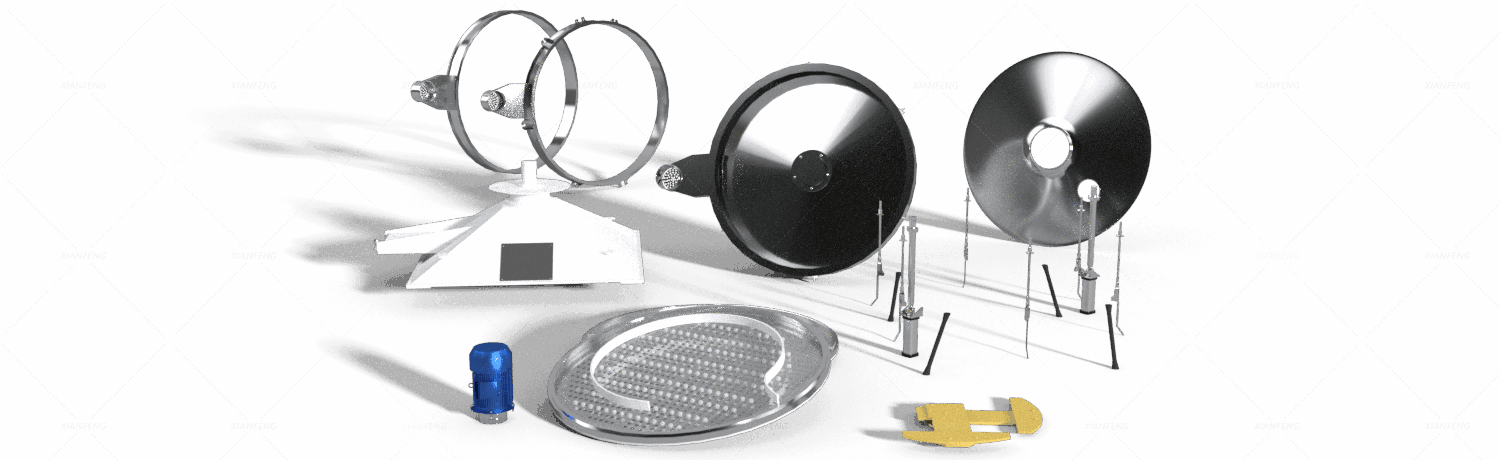

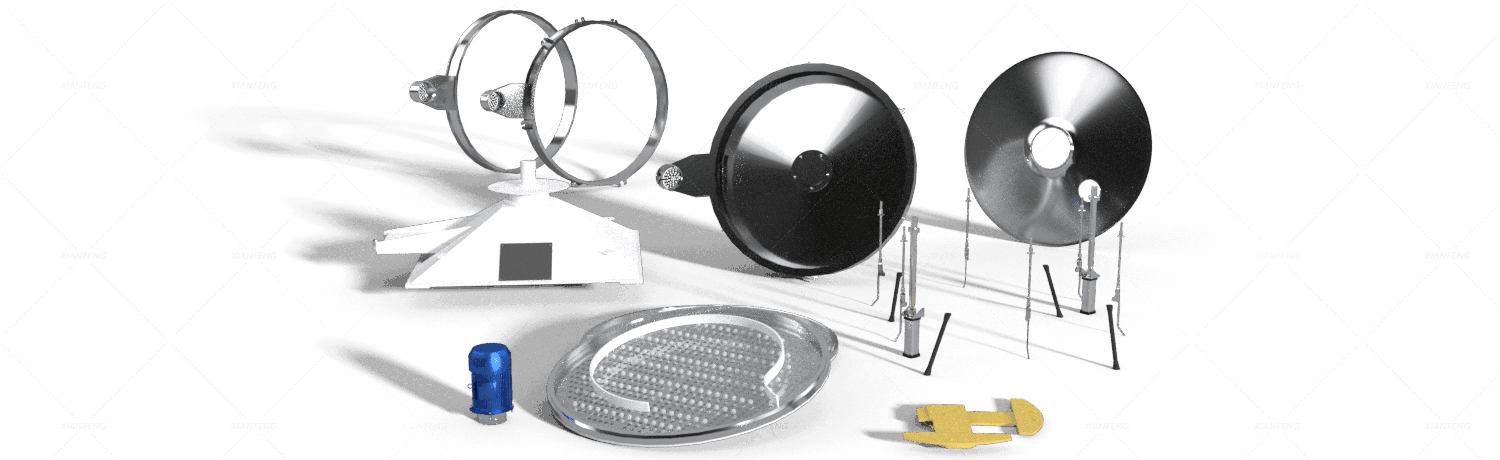

Feed inlet and surface technology

Discharge outlete

Screen components

Convenient device

Motor

Base components

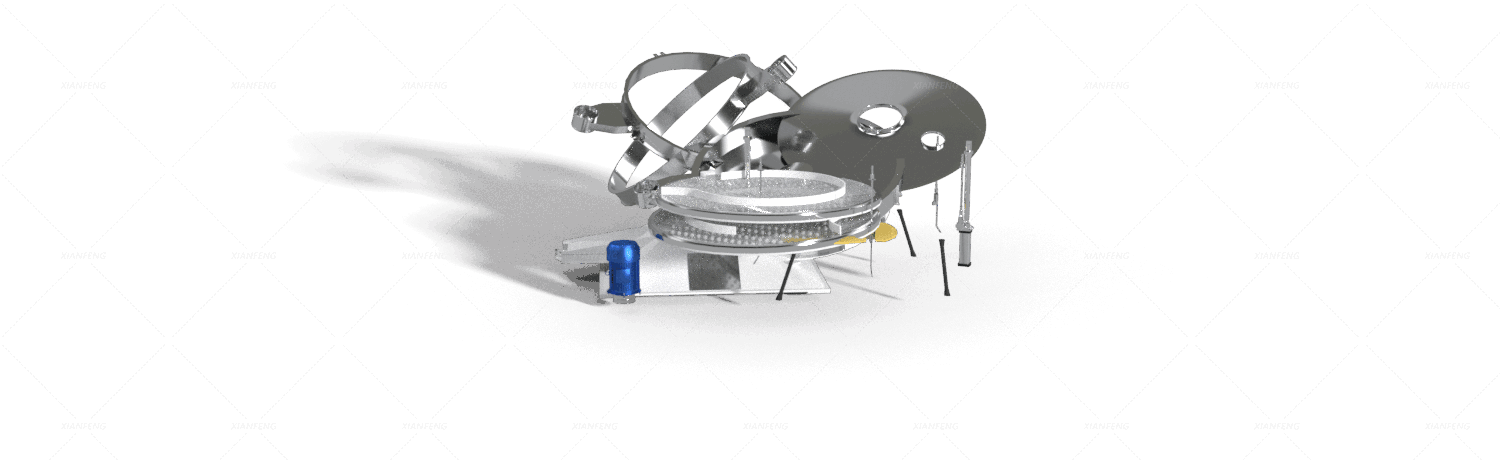

The feeding port can be customized as needed to match different unloading or conveying equipment, etc

The material mouth is finely polished and polished to prevent contamination of the material, and customized inspection holes can be used to observe the screening situation in real time

In addition to stainless steel material, surface sandblasting and PTFE coating processes can also be customized according to needs

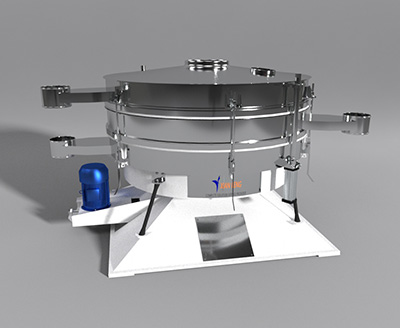

The discharge port can be customized according to needs, with fine polishing and grinding to ensure that there is no risk of material contamination

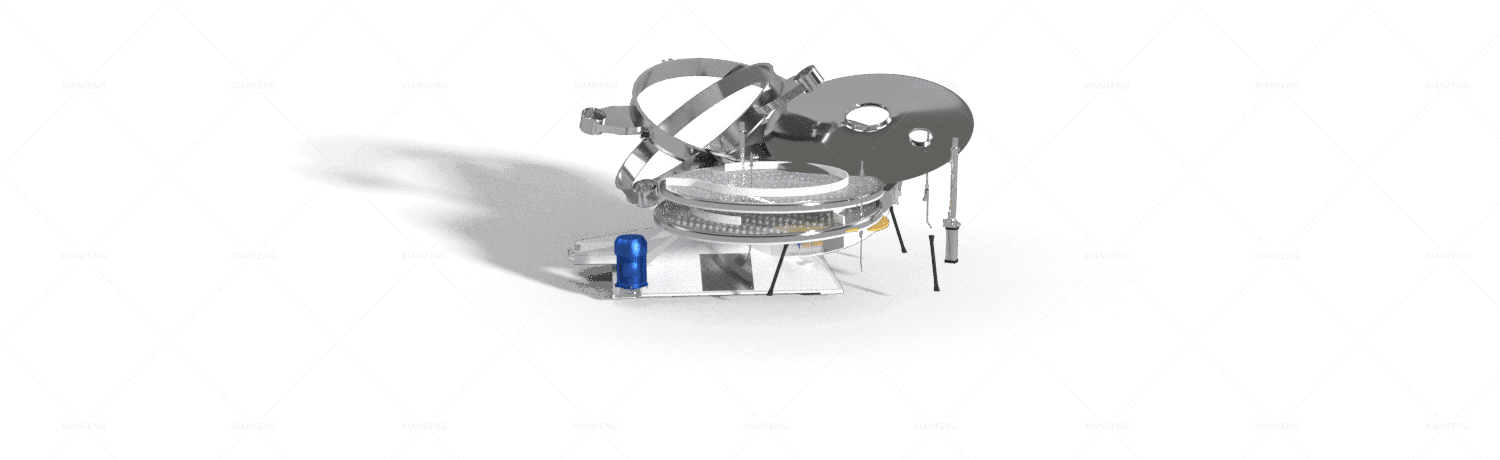

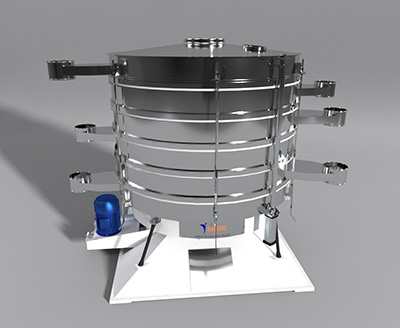

The mesh size is installed according to customer screening requirements, supporting 1-5 layers of screen mesh to simultaneously screen 6 different specifications of materials

Adding a guide strip device on the surface of the sieve allows the material to stay on the sieve surface for a longer period of time, resulting in finer screening. At the same time, adding elastic balls can solve the problem of clogged mesh holes

Usually capable of processing materials with a mesh size of 2-200, with the installation of an ultrasonic device, it can achieve material screening with a mesh size of 500, while also solving problems such as clogging of the mesh with ultrafine powder and electrostatic adsorption

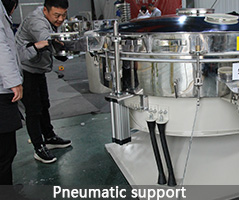

Pneumatic support devices can be customized according to needs, with functions such as quick opening of the device, making it more convenient to replace the screen mesh

Adopting imported ABB motors with high energy efficiency, stability, and durability, helping customers reduce downtime risks and save costs

High protection level to meet the requirements of gas and powder explosion-proof production environment

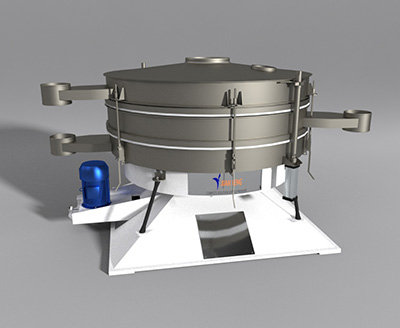

According to the model, single or double sets of springs are matched, and high elasticity metal composite springs are used. The external rubber wrapping has stronger load-bearing capacity and corrosion resistance

Adopting imported V-belt transmission, effectively protecting the block throwing device from slipping, reducing production line failure rate, and avoiding downtime losses

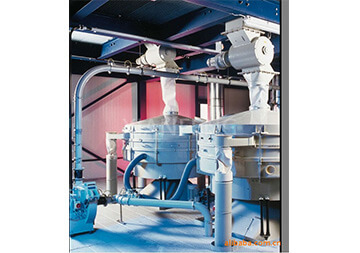

The core working principle of a circular swinging screen lies in its low-frequency three-dimensional compound motion (simulating the "tossing + flipping" action of manual sieving), which enables dry materials to achieve uniform distribution, efficient stratification, and precise sieving on the screen surface. Its motion characteristics are fundamentally different from the "high-frequency vibration" of a three-dimensional rotary vibrating screen, making it more suitable for sieving dry, brittle, adhesive, or easily agglomerated materials. Additionally, it helps avoid material breakage or screen clogging caused by high-frequency vibration.

ABB motor: Adopting Swiss ABB imported motor, low energy consumption and high efficiency

V-belt+swing block: The imported belt is sturdy and wear-resistant, and can run for a long time without any faults. The surface of the block is treated with phosphating to prevent rust and corrosion.

Multi layer screening box design: up to 5 layers of screens can be configured, with each layer working independently to achieve 6-level particle size separation. The screening box is made of Q235A carbon steel or stainless steel material, welded as a whole, and has a 30% increase in rigidity and strength compared to traditional screening machines.

Elastic support system: Rubber tension springs are installed at the bottom to effectively absorb vibration energy, reduce dynamic loads on the foundation (4-5 times lower than the vibrating screen), and reduce noise to below 75 decibels.

High precision mesh: Made of stainless steel woven mesh, polyurethane or nylon material, suitable for different material characteristics (such as food grade 304 stainless steel mesh to meet hygiene requirements). The tension of the screen mesh is controlled by a dedicated pressure rod or tie ring device, and the uniformity error of tension is less than 5%.

Intelligent cleaning system: standard with silicone rubber bouncing ball, high-frequency impact screen to remove adhesive substances; Optional ultrasonic system (20-40kHz) can be used to transmit sound waves to the screen surface through a transducer, solving the problem of blockage of micron sized materials and improving screening efficiency by more than 20%.

Variable frequency drive: It can adjust the motor speed in real time and match the optimal screening parameters for different materials (such as reducing the speed and increasing the residence time when dealing with viscous materials).

Fault warning system: Integrated temperature sensor (bearing temperature>70 ℃ alarm), vibration monitor (amplitude fluctuation>10% triggers shutdown), remote monitoring and data analysis through PLC.

Pneumatic lifting device: Large equipment is equipped with a hydraulic or pneumatic lifting system, which can lift the entire screen box by 300mm and achieve rapid screen replacement within 15 minutes.

Fully enclosed dust cover: using silicone sealing strip to avoid contaminating materials, combined with pulse dust removal interface, dust leakage rate<0.1kg/h meets production environment requirements.

A complete set of explosion-proof modifications can be customized to meet safety requirements for special production environments.

Tumbler screening machines

Powder screening machine | Sand screening

Fine powder screening machine | Aluminum powder screening

Drum screen|Silicon carbide screening

| Model | YBS-1200 | YBS-1600 | YBS-2000 | YBS-2200 | YBS-2600 | |

| Screen area(m²) | 1.13 | 1.85 | 2.63 | 3.8 | 5.3 | |

| Power(kw) | 2.2 | 3 | 4 | 5.5 | 5.5 | |

| Sieve accuracy(%) | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | |

| Screen layers | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | |

| Ball cleaning | 5 layers | 5 layers | 5 layers | 5 layers | 5 layers | |

| Ultrasonic cleaning | 5 layers | 5 layers | 5 layers | 5 layers | 5 layers | |

Higher Efficiency: Materials are evenly dispersed across the screen surface, eliminating accumulation and dead zones. The screening efficiency for the same material is 20%-30% higher than a linear screen and 15%-25% higher than a rotary vibrating screen (for example, when screening 100-mesh flour, the hourly output can reach 8-12 tons/hour, compared to only 5-7 tons/hour for traditional screens).

More Stable Accuracy: The amplitude and frequency can be infinitely adjusted via a frequency converter to accommodate different particle sizes (such as fine powder, coarse particles, and sticky materials). The screening accuracy error is ≤1% (compared to 3%-5% for traditional screens), and the screened material remains intact (especially suitable for fragile items such as plastic particles and food granules).

Lower Noise: Operating noise is ≤75dB (compared to approximately 85-90dB for traditional rotary vibrating screens), meeting European and American factory noise standards and eliminating the need for additional soundproofing.

Yes. We offer three custom designs for sticky materials: The screen features a "self-cleaning structure": Optional bouncing balls (rubber or silicone, tailored to the material's hardness) or an ultrasonic screen cleaning device instantly remove stuck materials from the screen aperture, reducing clogging by over 90%. The screen's tilt angle is adjustable (0-5°): Adjusting the angle accelerates material flow and prevents stagnation on the screen surface. Anti-stick coatings (such as Teflon) are applied to material-contacting parts to reduce material adhesion. This is particularly suitable for sticky materials (such as wet starch and resin particles) in the food and chemical industries.

It can achieve "multiple uses with one machine." Our circular swing screen features a modular design: the screens can be quickly replaced (snap-on fastening, tool-free, and completed by one person in less than 5 minutes). It supports switching between screens of varying mesh sizes (10-500 mesh) and materials (stainless steel woven mesh, perforated mesh, and nylon mesh). The feed inlet is equipped with a "divider" to adjust the material distribution width to meet the dispersion requirements of materials of varying particle sizes. The discharge port can be configured with multiple grading outlets (e.g., 2 levels for a single screen layer, 4 levels for a third screen layer). This allows a single device to perform "coarse screening, fine screening, and grading," eliminating the need to purchase separate equipment for different materials.

We support fully explosion-proof customization, complying with EU ATEX and North American Class I/II Division certification standards. The motors are explosion-proof (Ex d IIB T4 Ga, upgradeable to meet hazardous area levels). The electrical system (inverter, control cabinet) is explosion-proof and sealed, and cables are routed through explosion-proof conduit. For contact parts involving flammable materials (such as plastic particles or solvent mixtures), anti-static materials are used and grounded to eliminate the risk of static sparks.

It is fully compatible and CE certified. It supports mainstream global voltages (110V/220V/380V/415V) and frequencies (50Hz/60Hz) and can be customized to your target market (e.g., North America, Europe, Southeast Asia, etc.). The motor features IP54 protection, making it suitable for high-temperature, dusty industrial environments and ensuring stable operation under the local power grid.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.