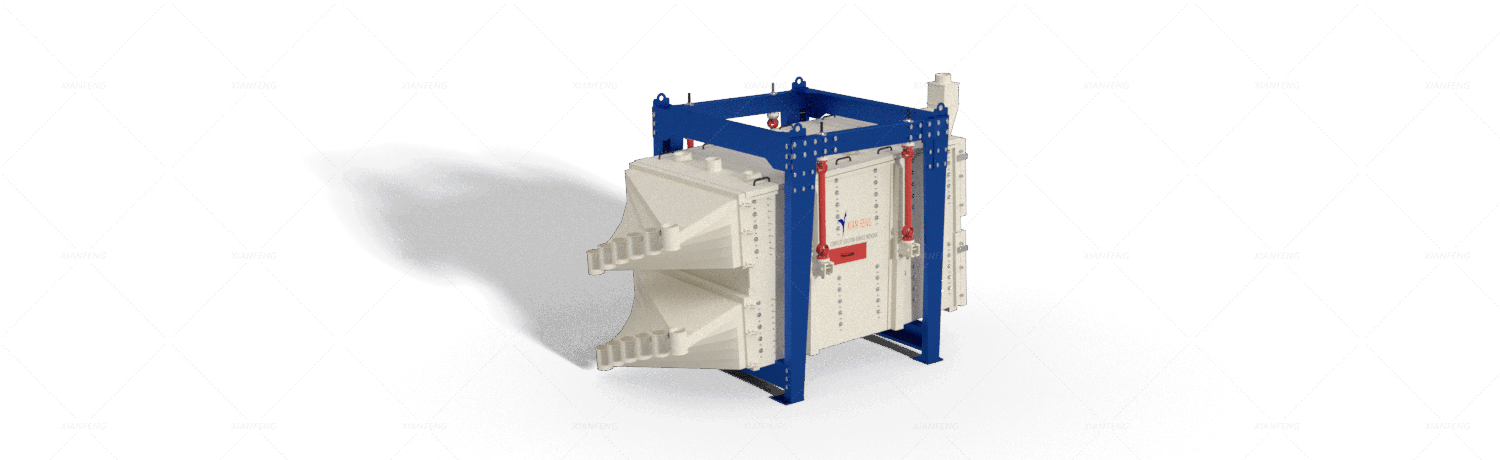

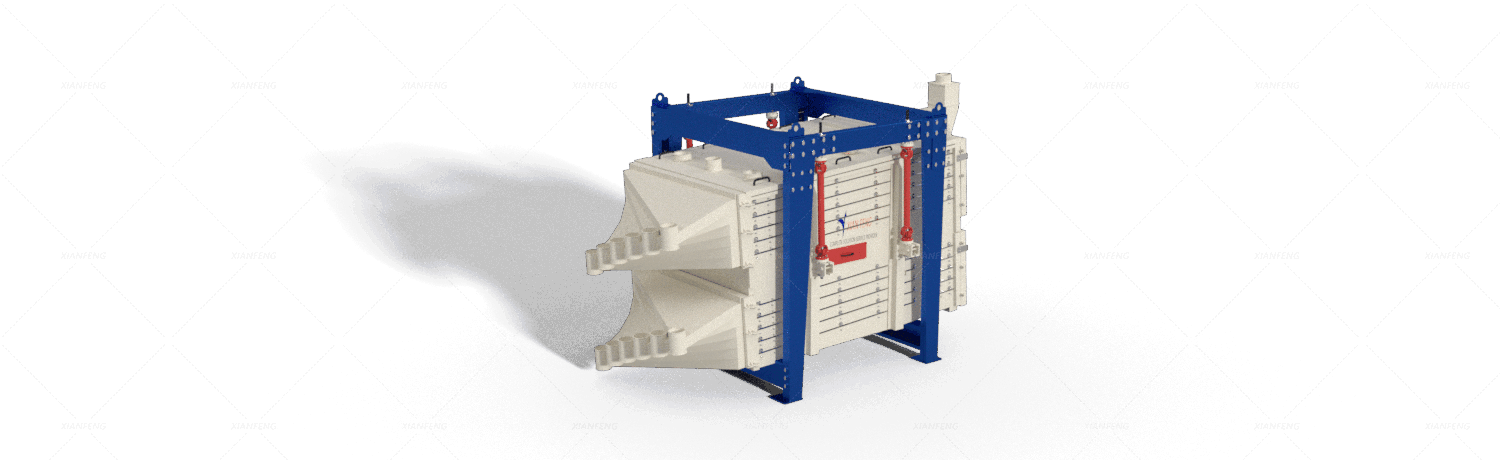

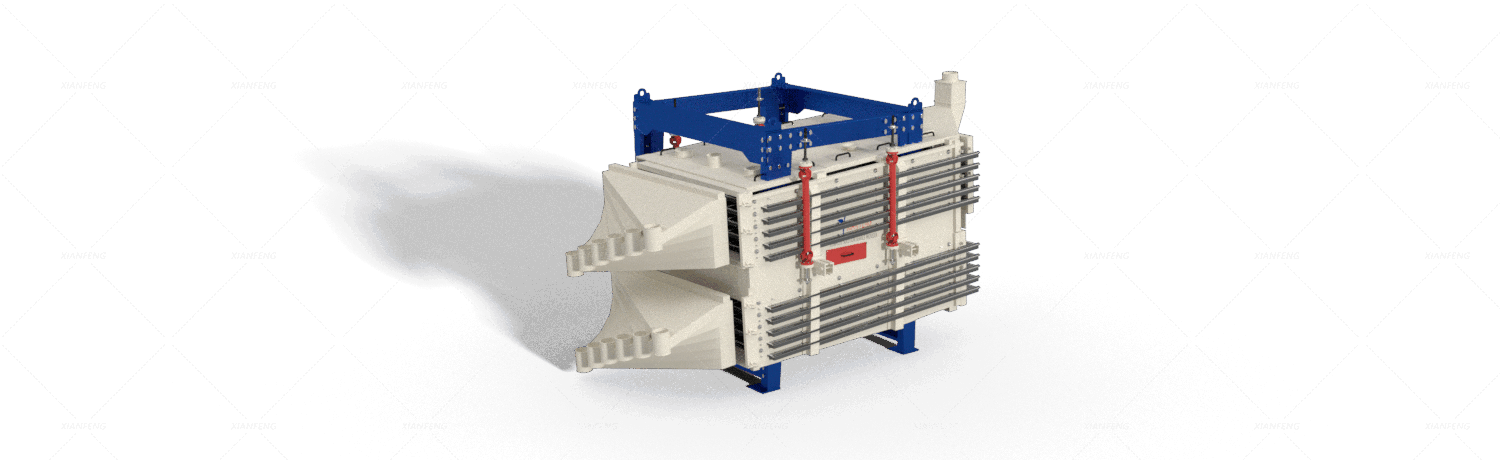

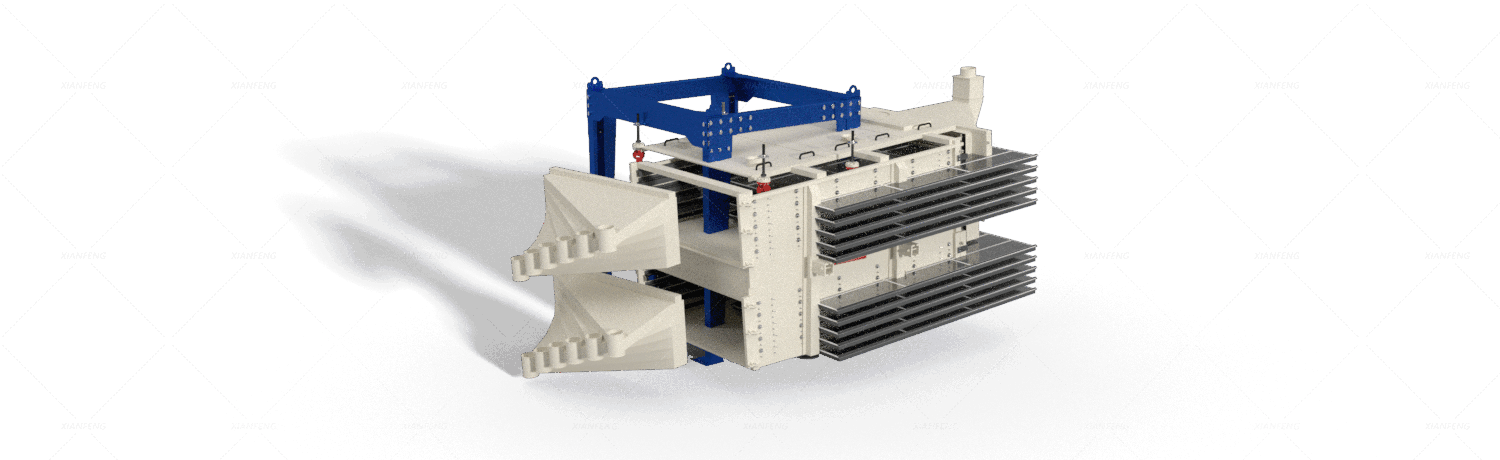

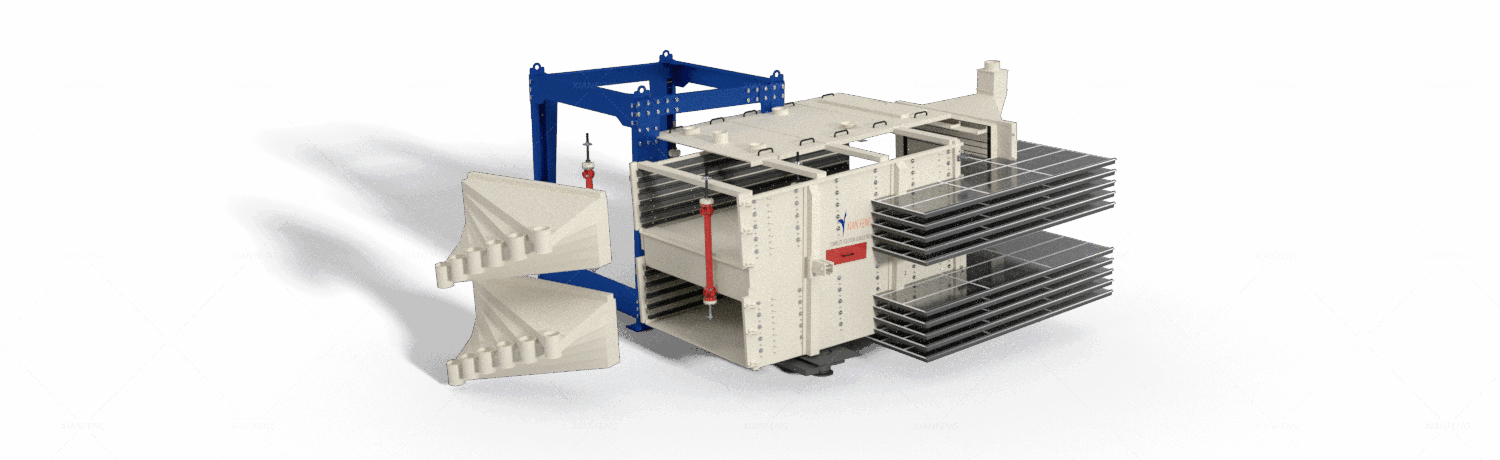

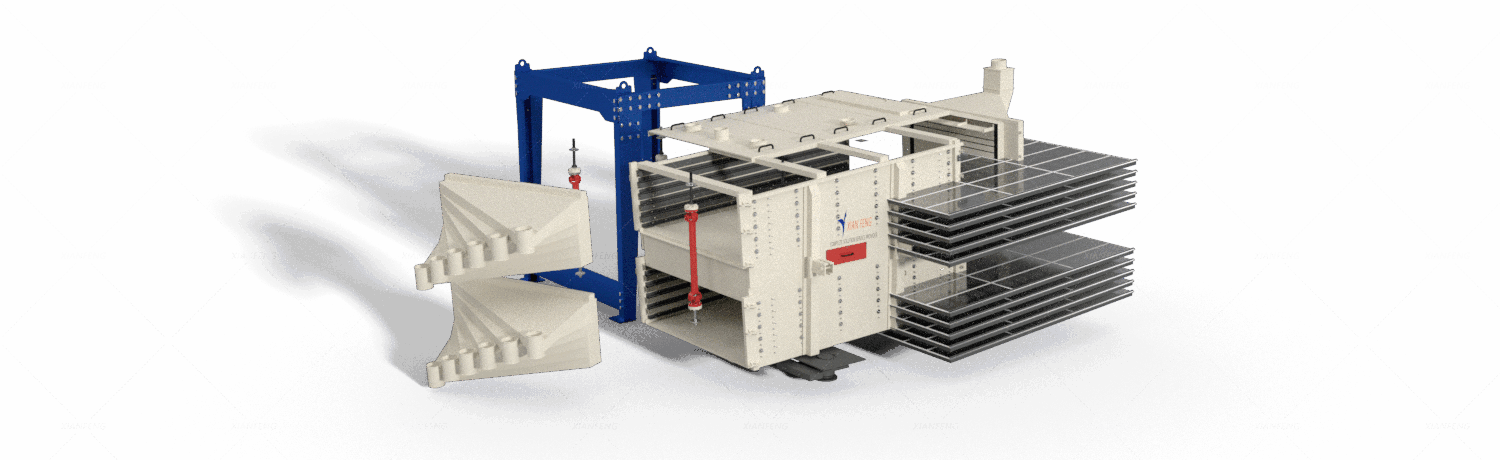

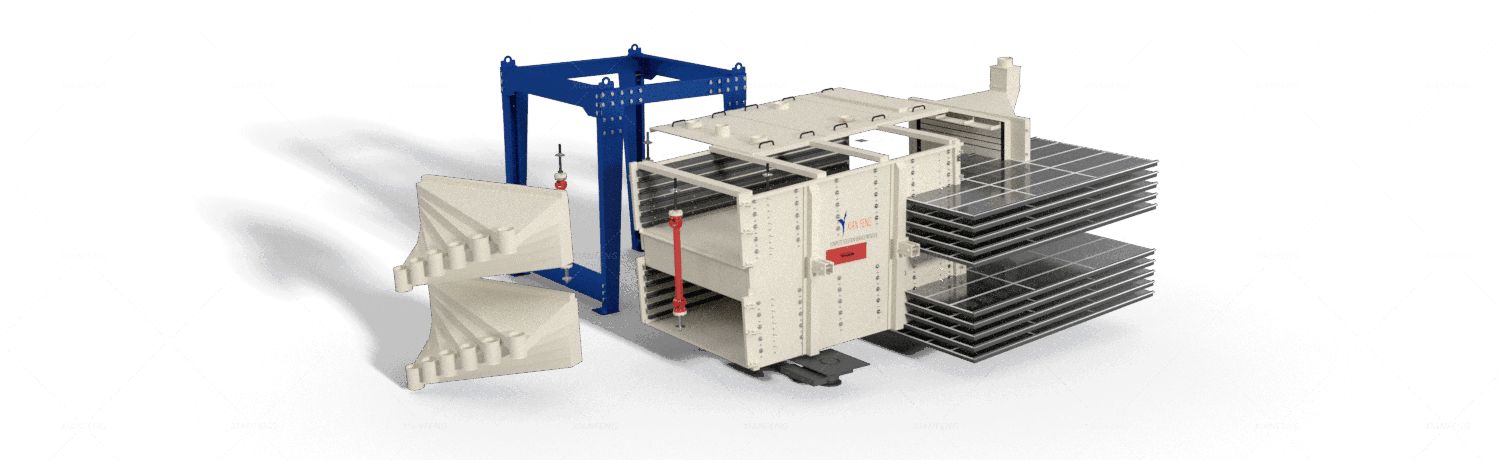

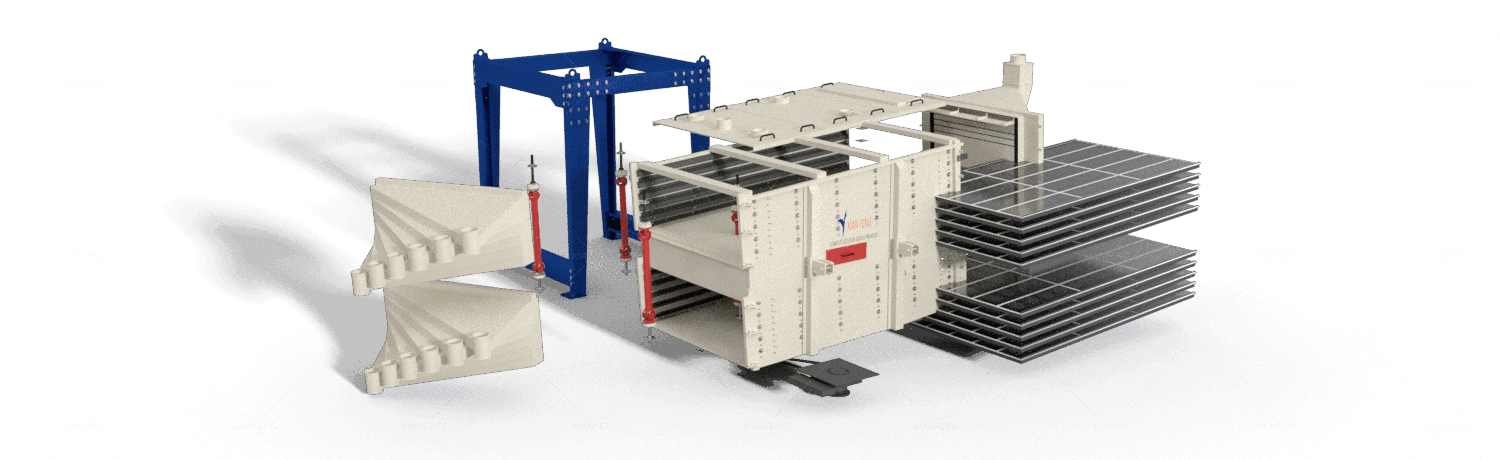

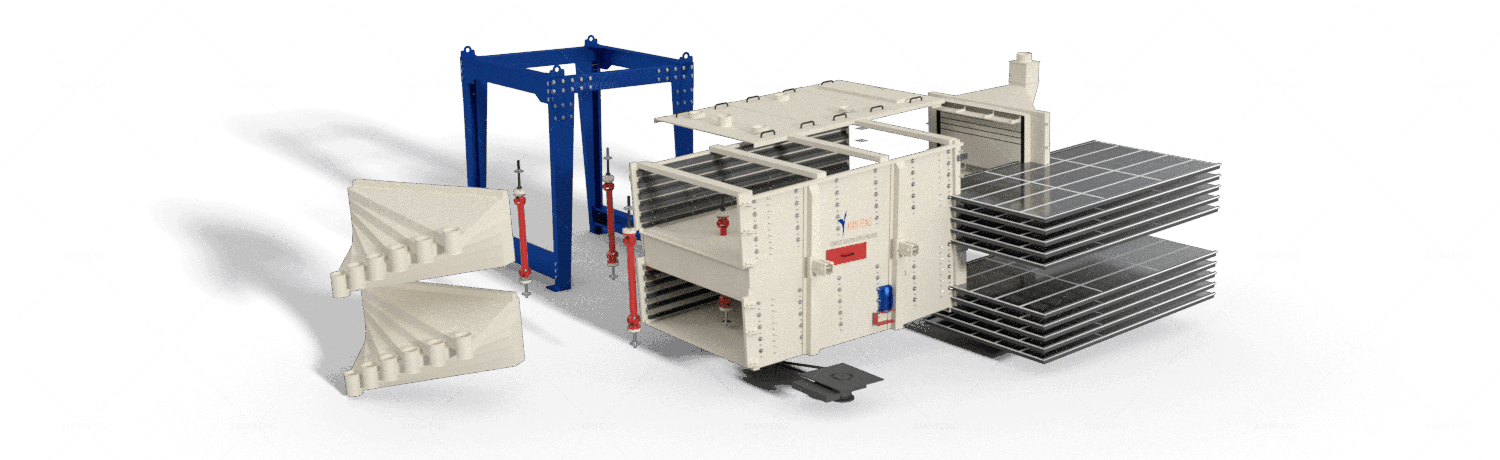

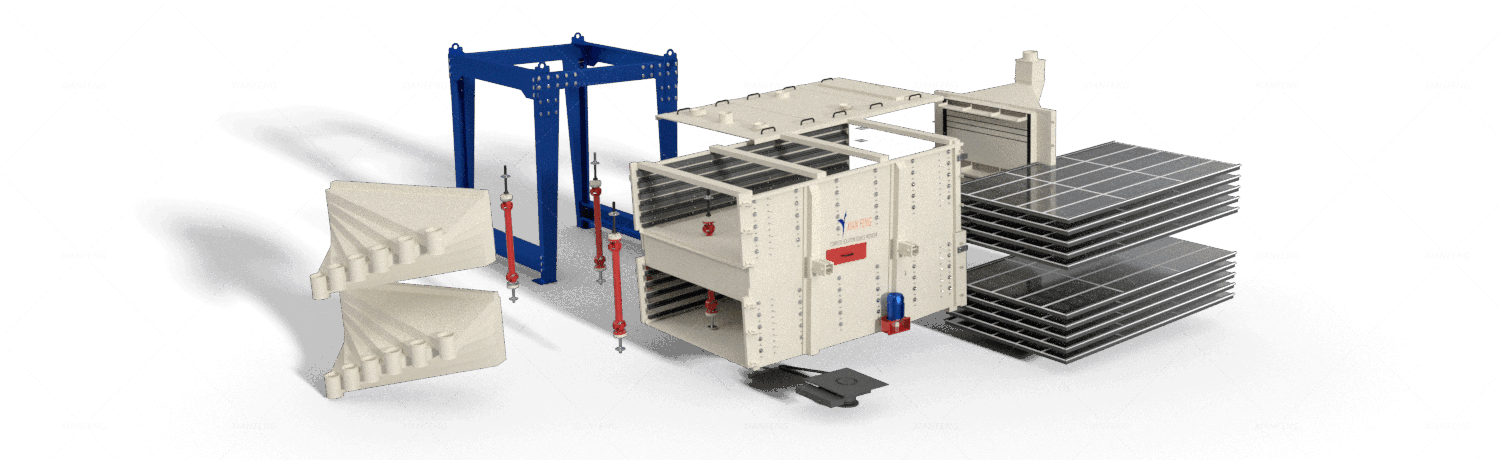

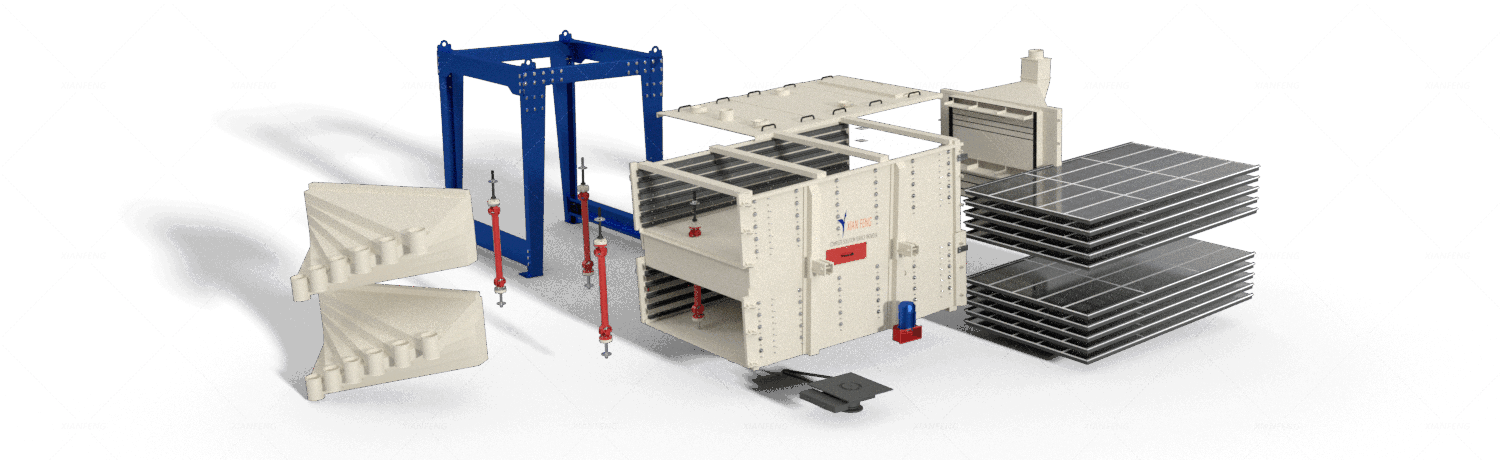

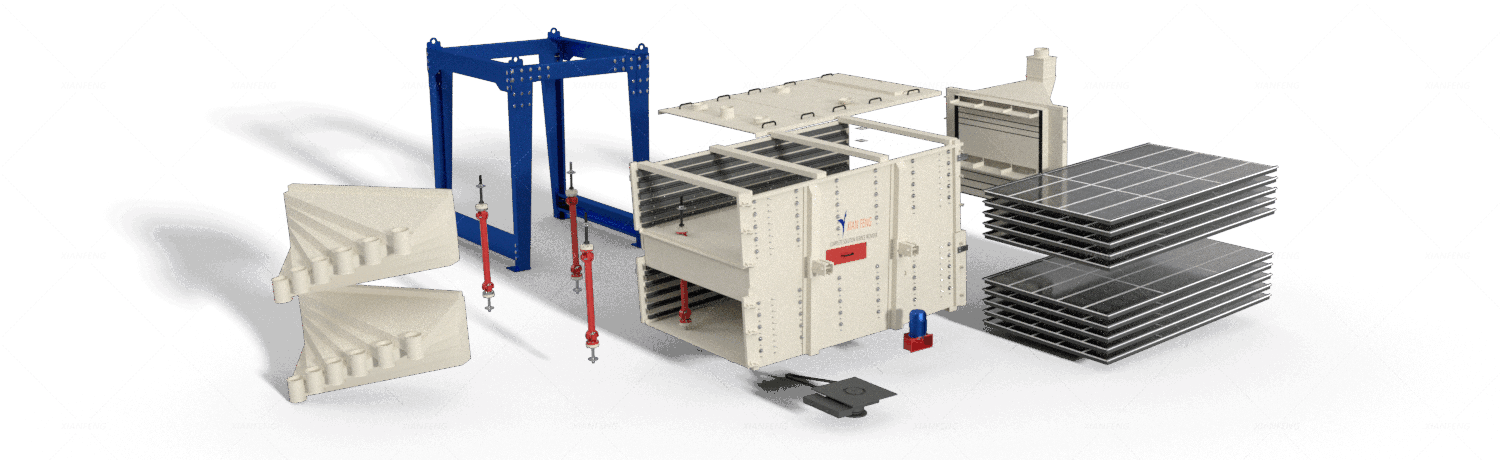

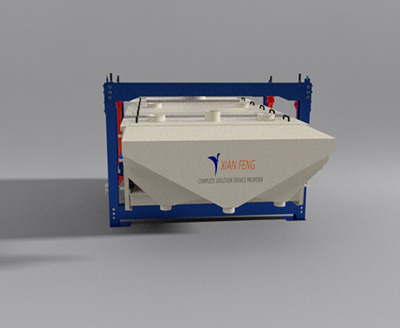

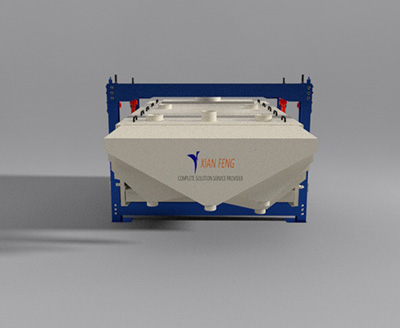

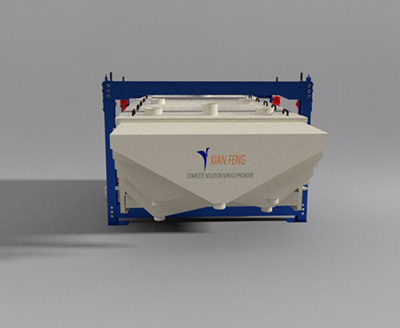

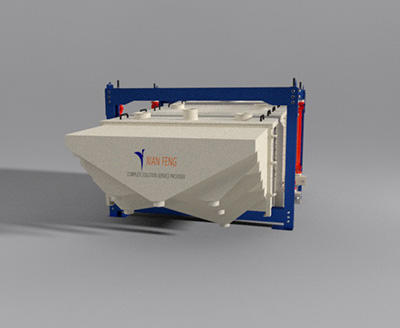

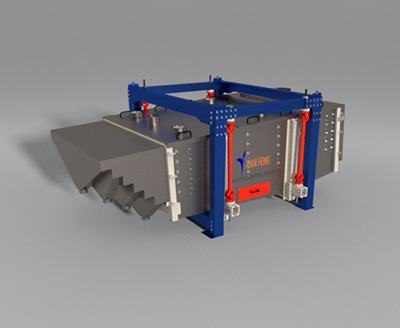

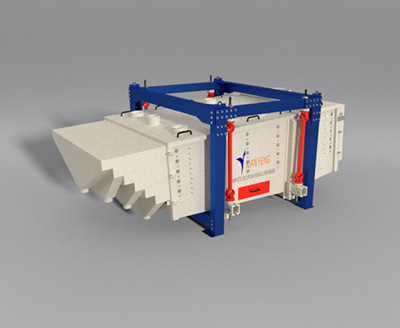

Gyratory Sifter, also known as Reciprocating Gyratory Screen, is a large-scale screening equipment developed specifically to meet the high-precision screening and high production requirements of customers. The principle is that the motor drives the counterweight block to provide power, and the screening machine performs planar rotary motion. The material rotates forward on the screen surface, and each layer of ball support plate has 600 cleaning silicone elastic balls to provide cleaning effect, allowing the material to quickly pass through the screen for size classification. It is commonly used in the food, chemical, metallurgical, and building materials industries. Common materials include quartz sand, fracturing sand, ceramic particles, salt, calcium carbonate powder, etc. The two specifications of independent and double composite can meet different production requirements and can be combined in batches to achieve screening on the production line.

iron ore, coal, quartz sand, fracturing sand (ceramic grain sand), perlite, calcite, potassium feldspar, dolomite, etc.

aluminum powder, iron powder, copper powder, tantalum powder, aluminum oxide powder, magnetic materials, metallic silicon, etc.

Soda ash, urea, resin, melamine, plastic masterbatch, fertilizer raw materials, etc.

Flour, Starch, Sugar (White Sugar/Sugar), Salt, Milk Powder, Grains, Feed, etc.

tablets/powders (pharmaceutical industry), waste plastics/glass (environmentally friendly recycling), abrasives (such as silicon carbide), refractory materials.

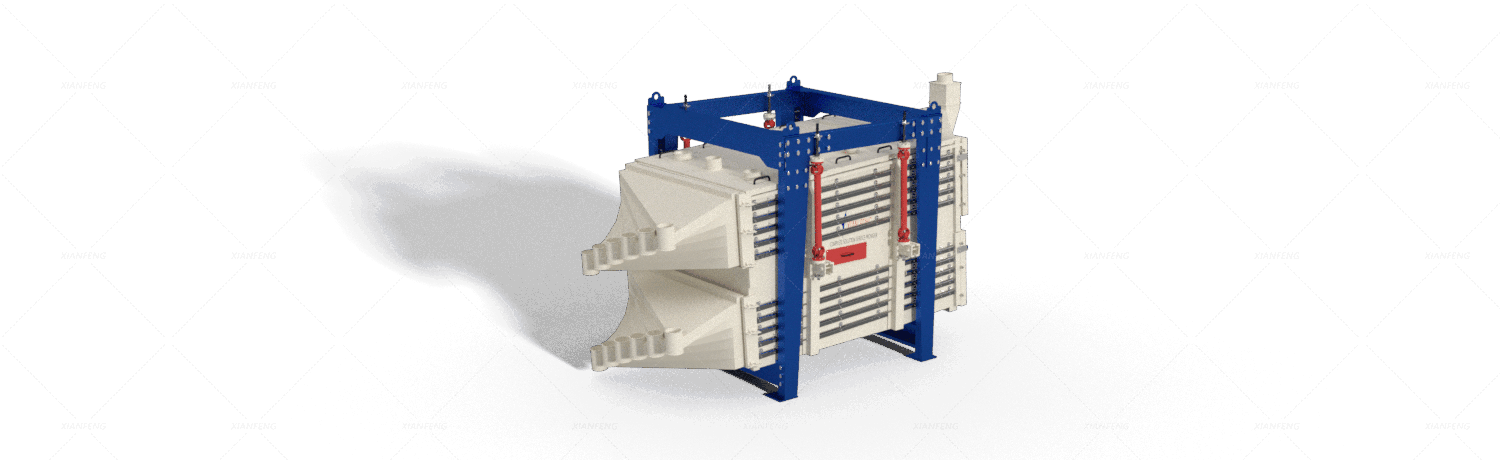

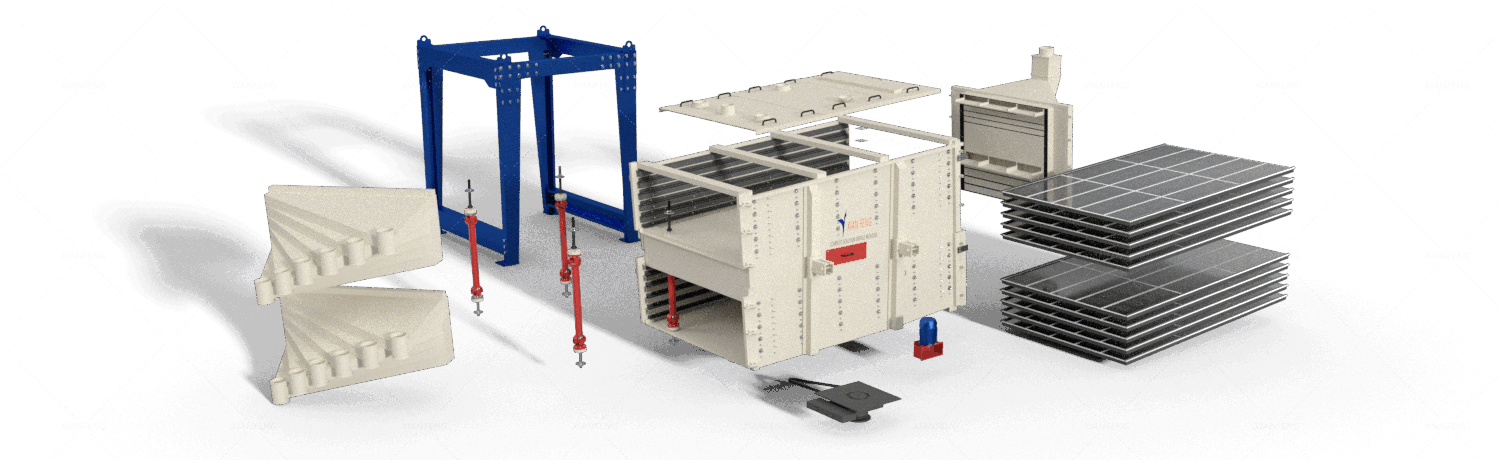

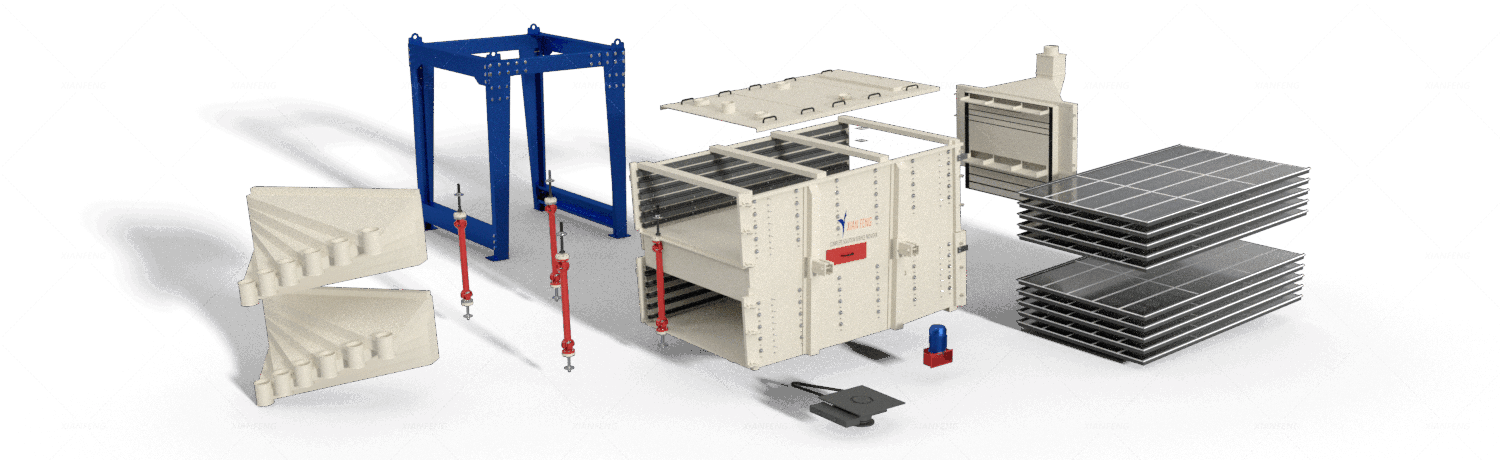

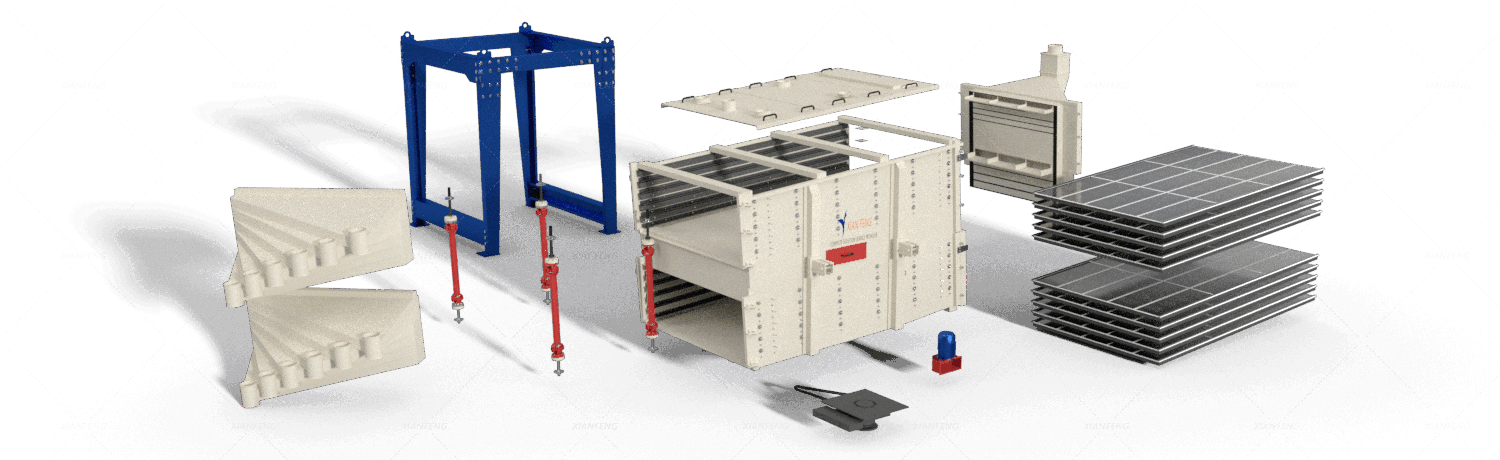

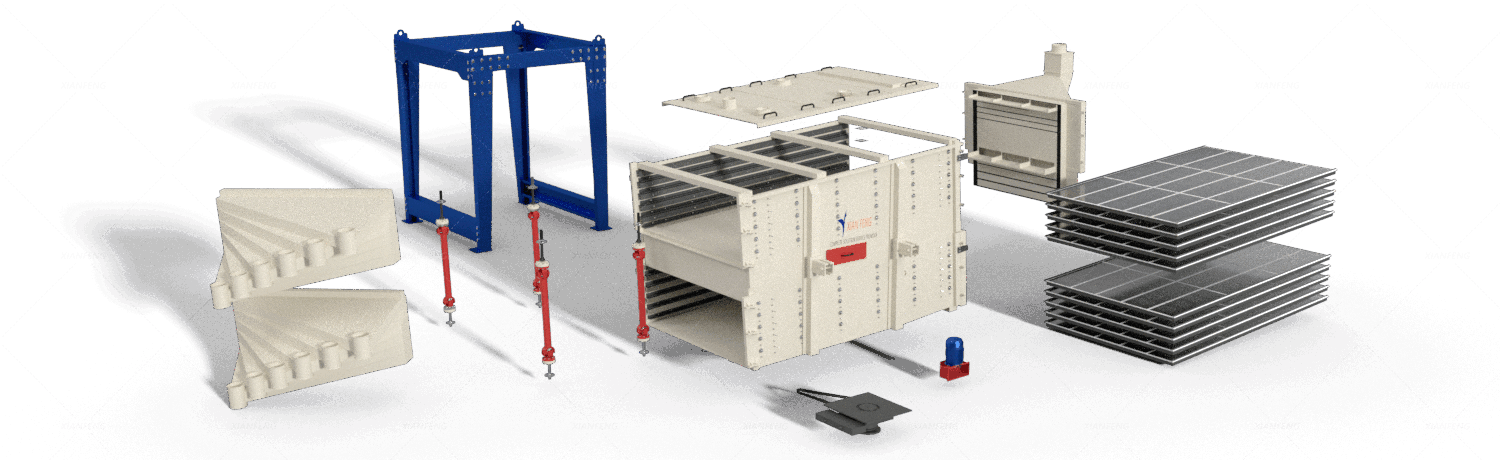

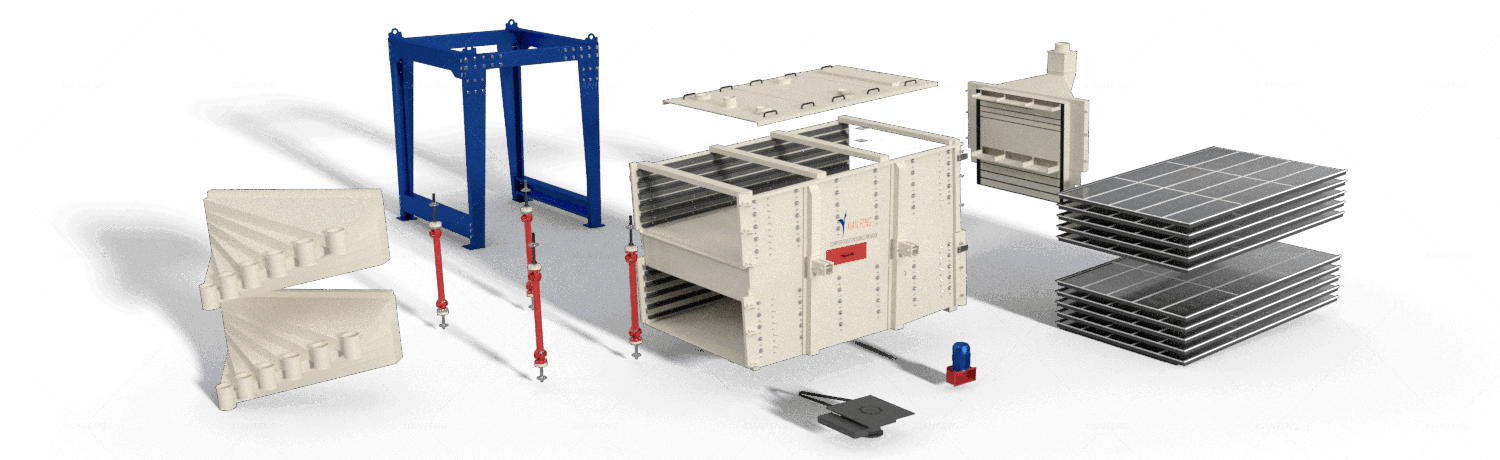

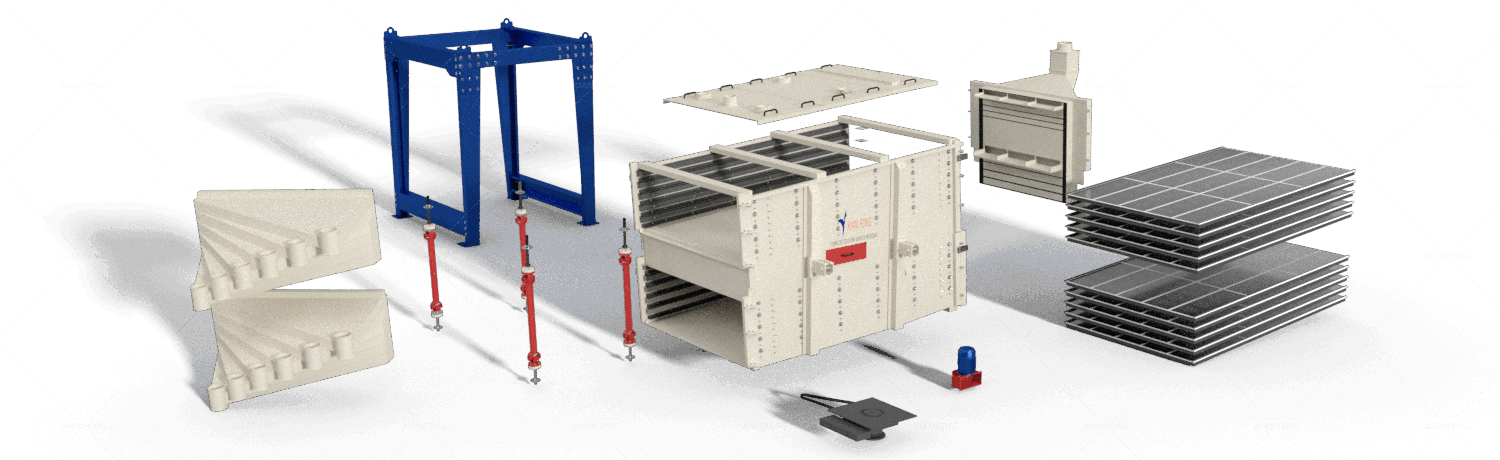

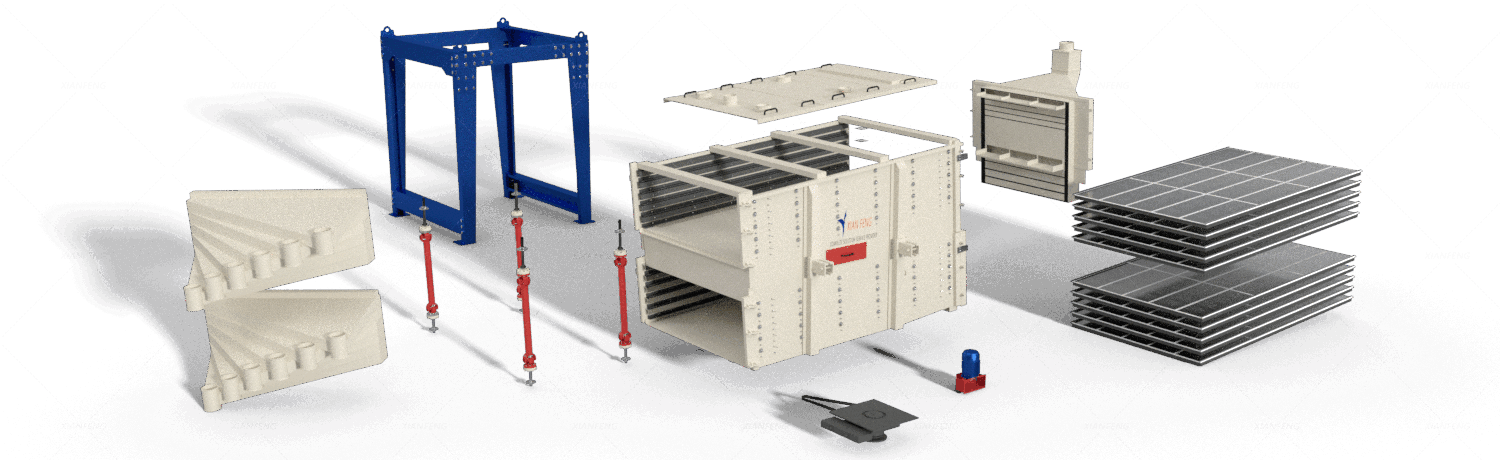

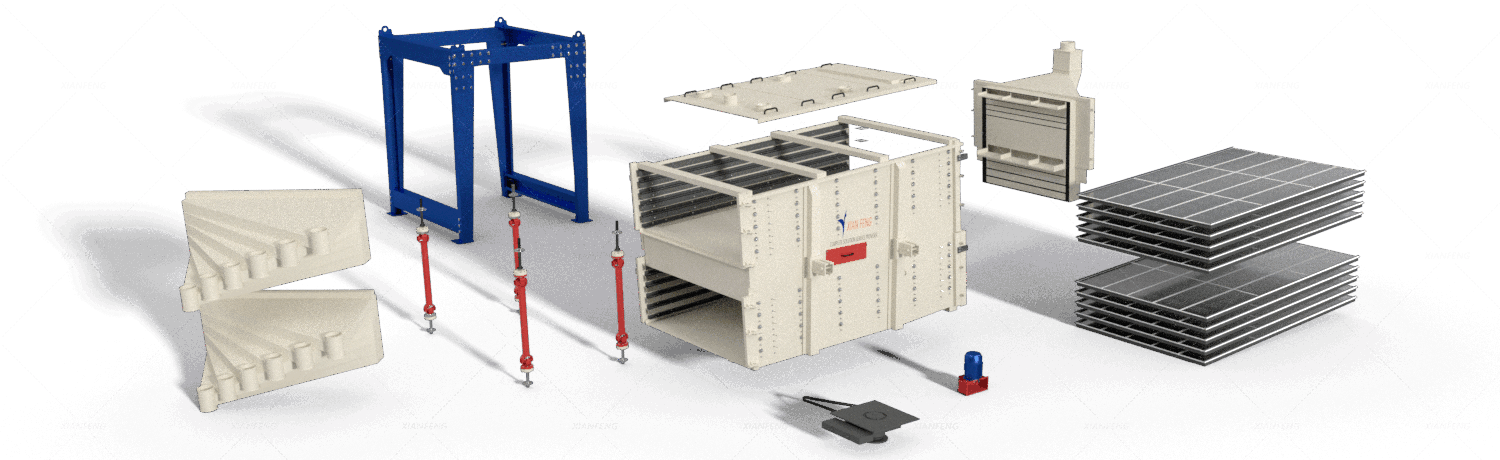

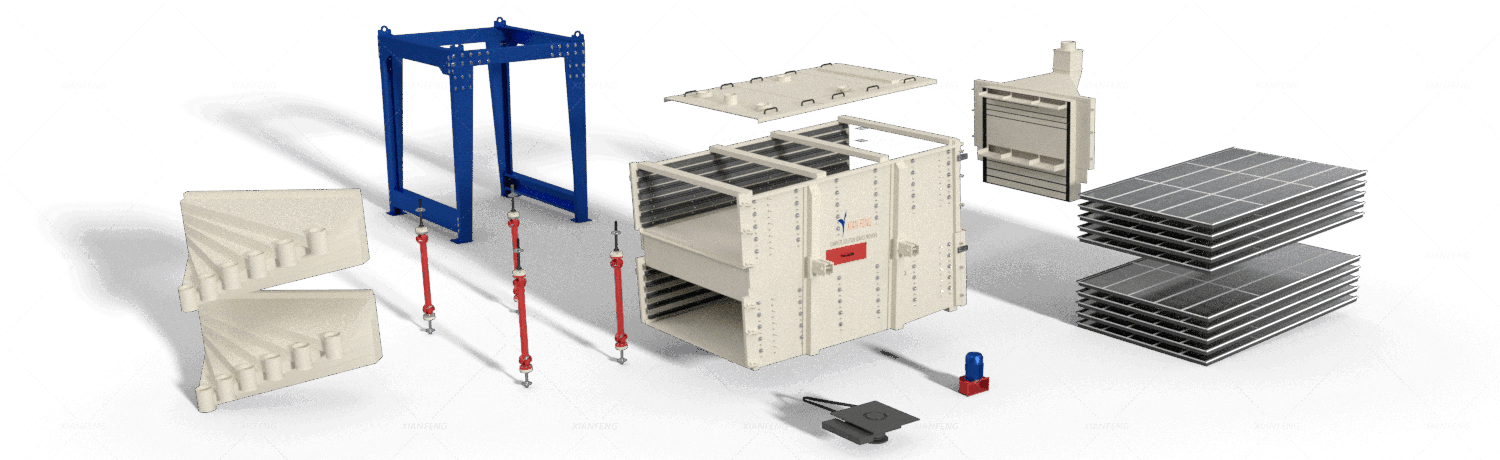

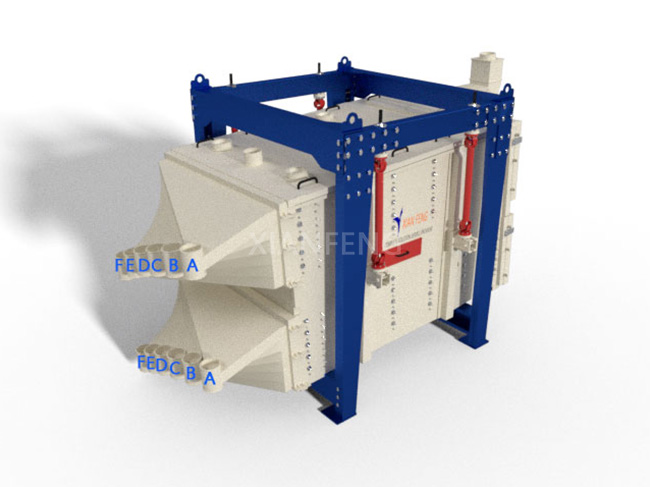

Feed inlet and distribution

Screen components and seals

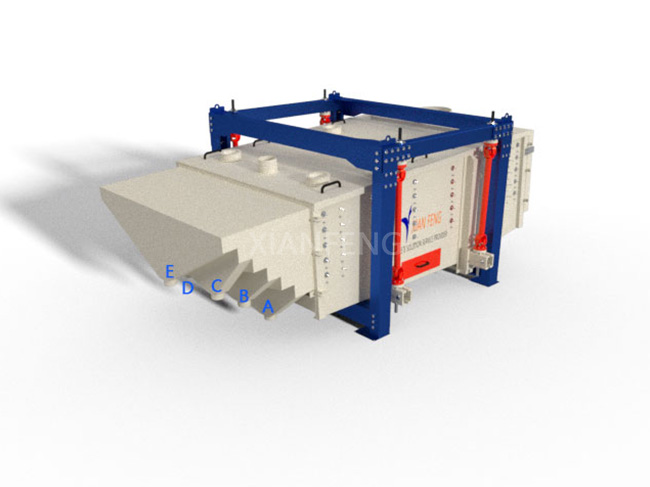

Discharge outlet

Bearings and motors

Drive shaft and fixation

Framework

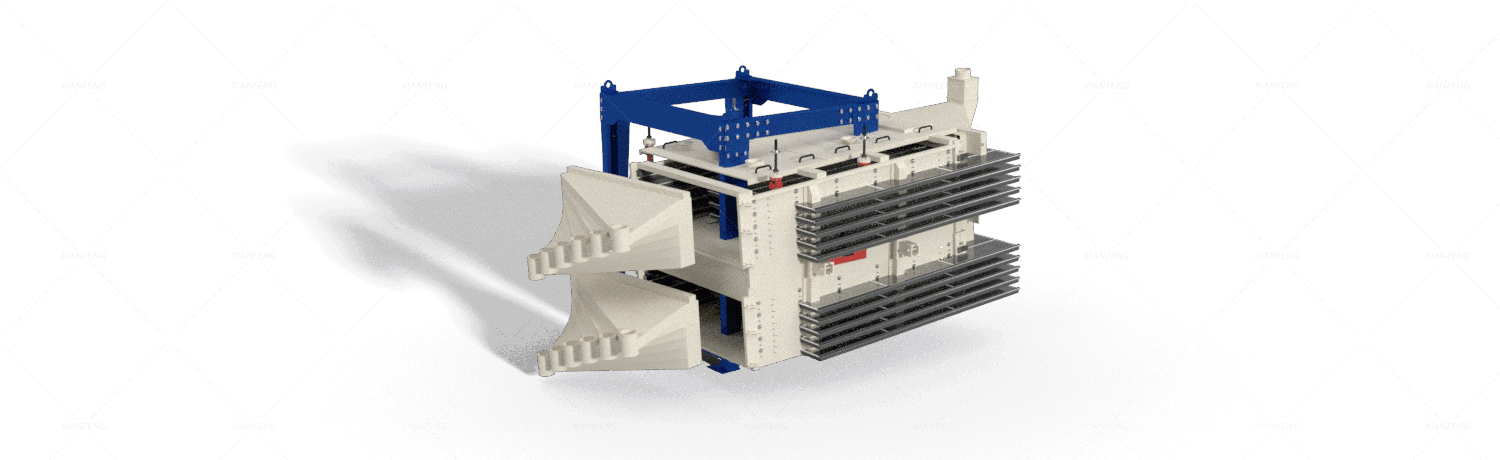

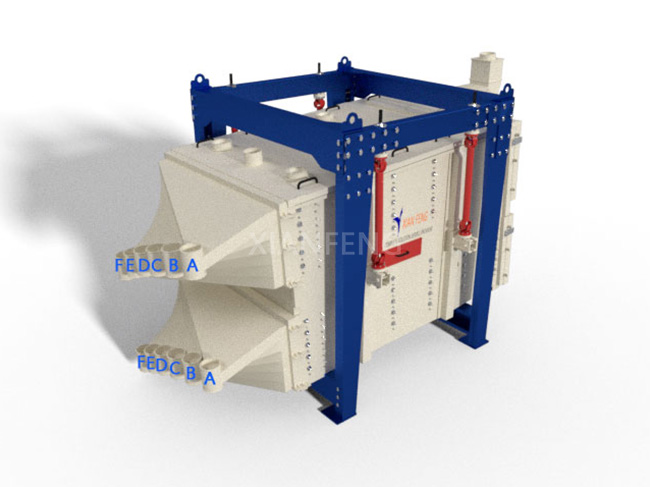

Feed inlet link, precise size can be customized and matched with different feeding equipment according to needs.

The sealing strip of the back cover is tightly sealed to prevent dust leakage.

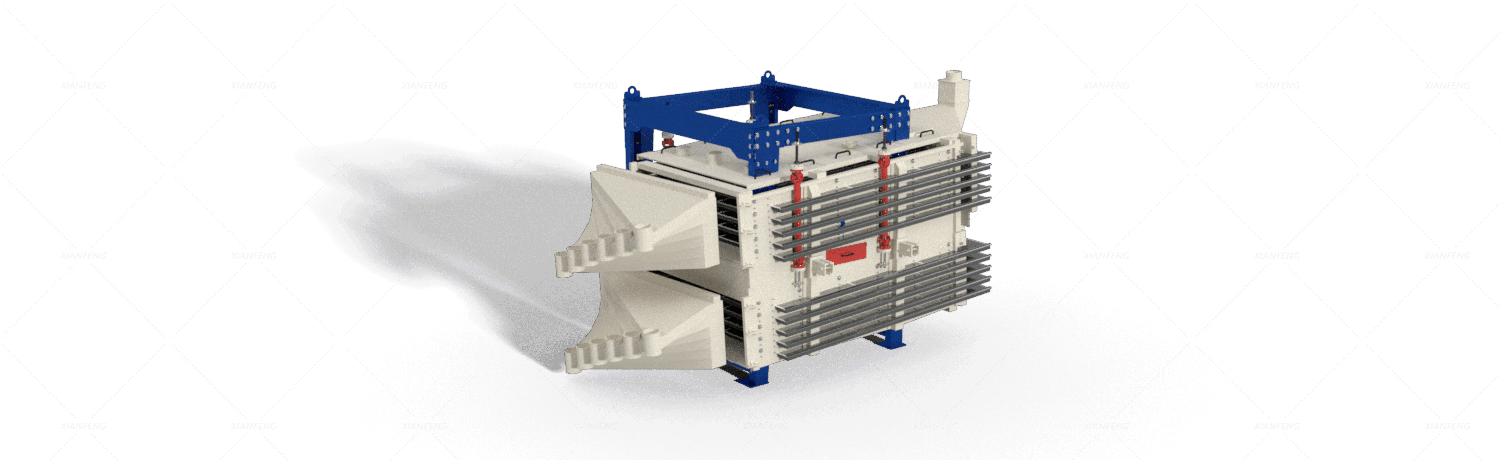

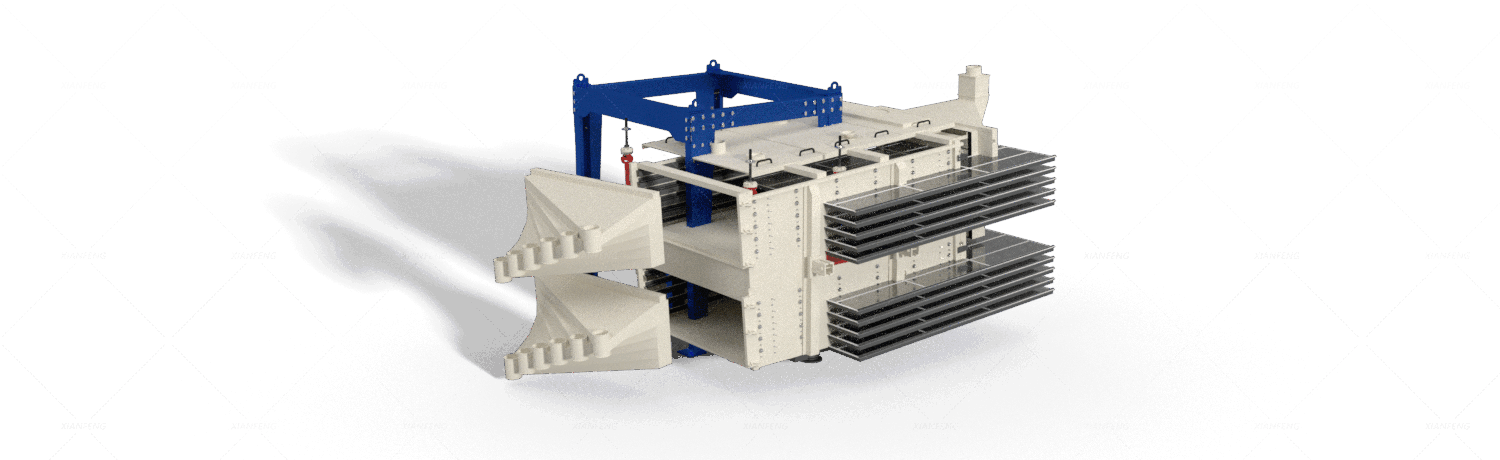

The material diversion device realizes double layered screening for retesting, doubling the output of one equipment.

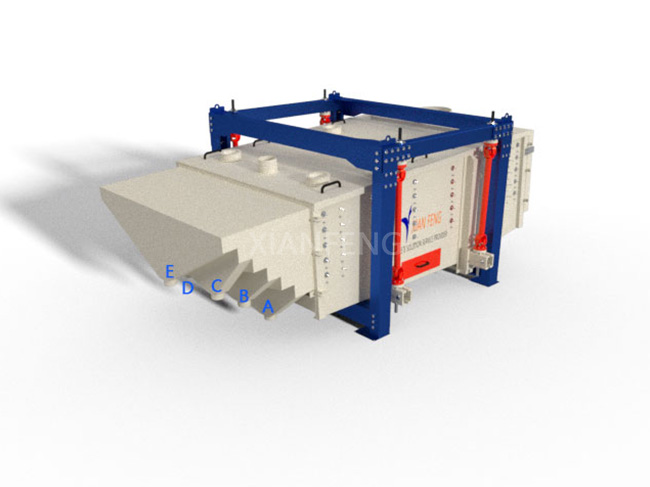

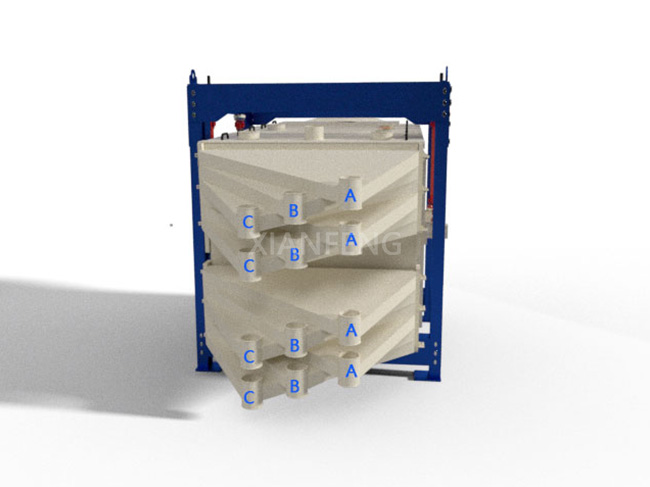

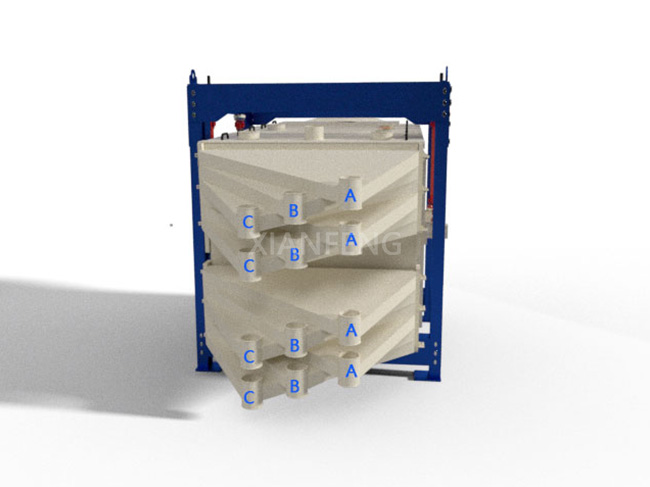

The mesh size of the screen mesh is precise, and the adhesive cloth strip process corresponds to the position of the rubber strip on the screen frame, reducing the stress distribution of the screen mesh and extending its service life.

XIAN FENG's unique wavy tray design increases the rebound frequency of the elastic ball and improves the net cleaning effect by 30%.

Each layer uses 600 silicone elastic balls, exceeding the industry standard of 400, and is matched with two irregular elastic balls per grid. The edges are cleaned without dead corners, anti blocking nets, screening accuracy, and production are effectively improved.

The discharge port can be customized according to needs. Screening from layers 1 to 10.

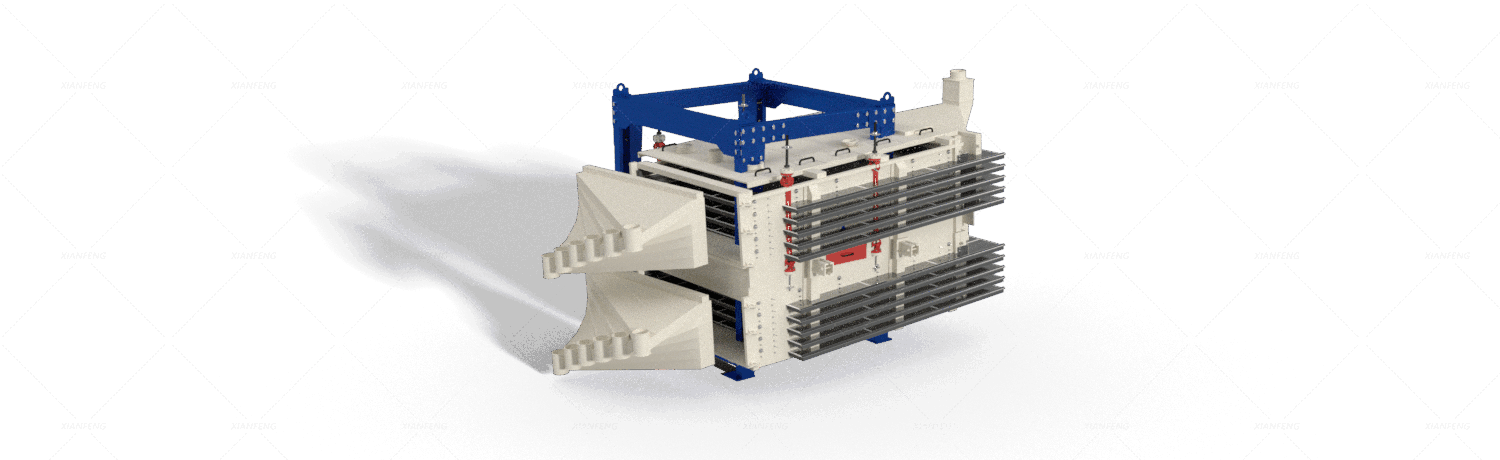

The riveting process has high strength, with a hook plate design and a quick opening device for easy replacement of the screen mesh.

Thicken the fixed components to avoid the risk of breakage accidents during personnel operation.

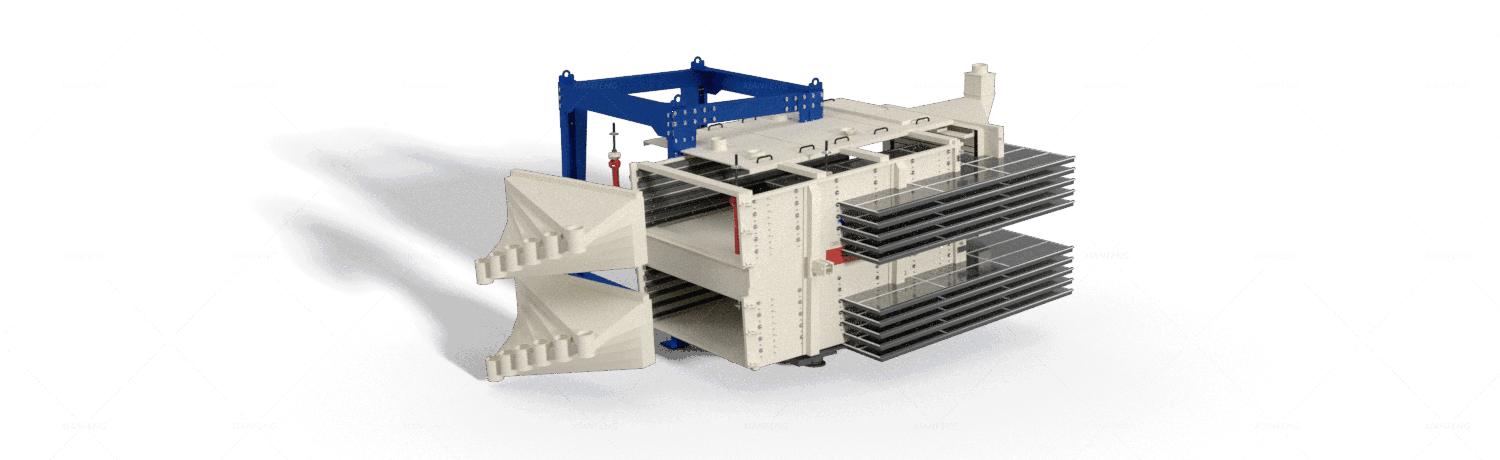

Adopting imported Swiss ABB motors with low power consumption, high performance, and low failure rate.

Using imported Swiss SKF bearings, it is possible to achieve a 10-year surface oiling.

Adopting imported Japanese Three Star transmission belt, it is non slip, wear-resistant, and fracture resistant.

Bold transmission shaft, mid position, low position design, suitable for both compound screening and single screening square swing screens.

High strength, no breakage, smooth transmission, ensuring efficient screening.

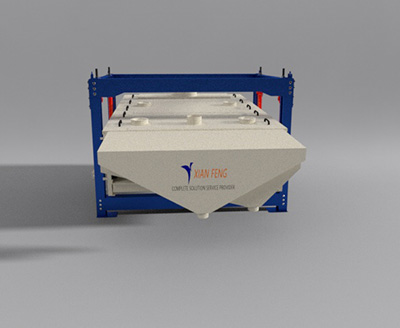

The thickened frames have been reasonably designed by XIAN FENG's technical department and subjected to multiple anti fatigue tests by the quality inspection department.

Paired with riveting technology, it ensures strength while effectively reducing the construction period.

The working principle of the square swing screen is as follows: using a three-phase asynchronous motor as the power source, the motor is connected to an eccentric shaft through a coupling, and combined with two side rollers or slider type guide mechanisms, Like circular swing screen products,it converts its own rotational motion into a composite motion of "horizontal reciprocating swing+slight up and down swing" of the screen body. After the material enters from the upper feeding port, it quickly diffuses uniformly to both sides and below of the screen surface under the combined action of the swing force of the screen body and the 1-5 ° inclined screen surface. During the movement process, fine particles pass through the screen holes under the action of the swing, while coarse particles continue to move forward. If 1-5 layers of screen mesh are configured with decreasing mesh size from top to bottom, it can also achieve "one-time feeding and multi particle size classification". Finally, materials of different particle sizes can be classified from top to bottom. Corresponding discharge outlet for discharge; This composite motion not only reduces the problem of clogging and avoids mixing, but also increases processing capacity due to the large effective area of the square screen surface, resulting in low noise and less wear, thus achieving efficient, high-precision, and low loss screening effect.

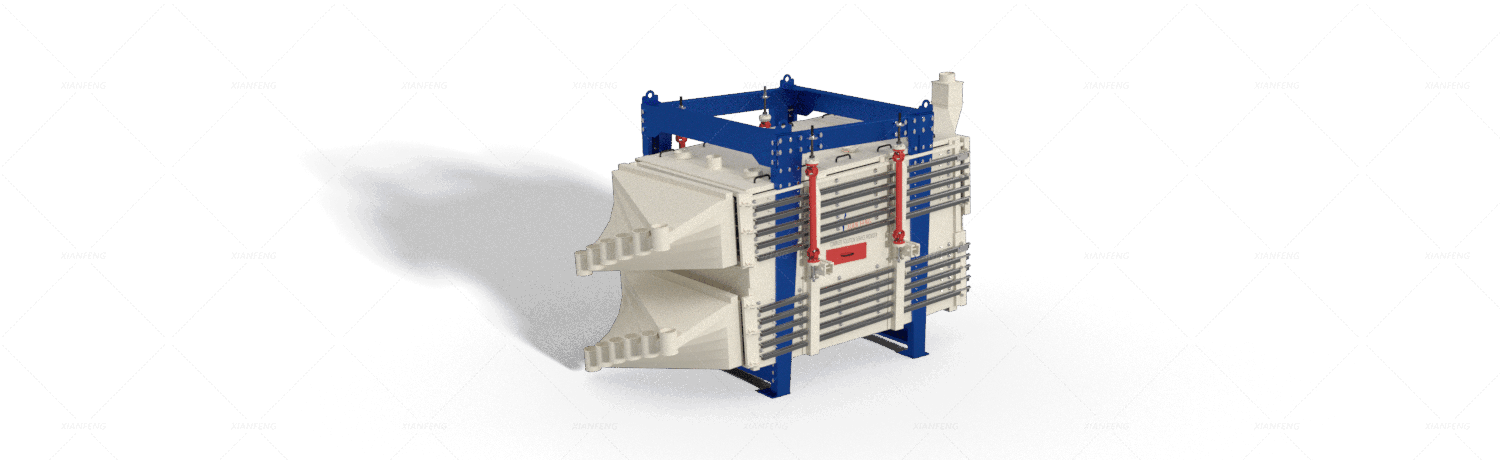

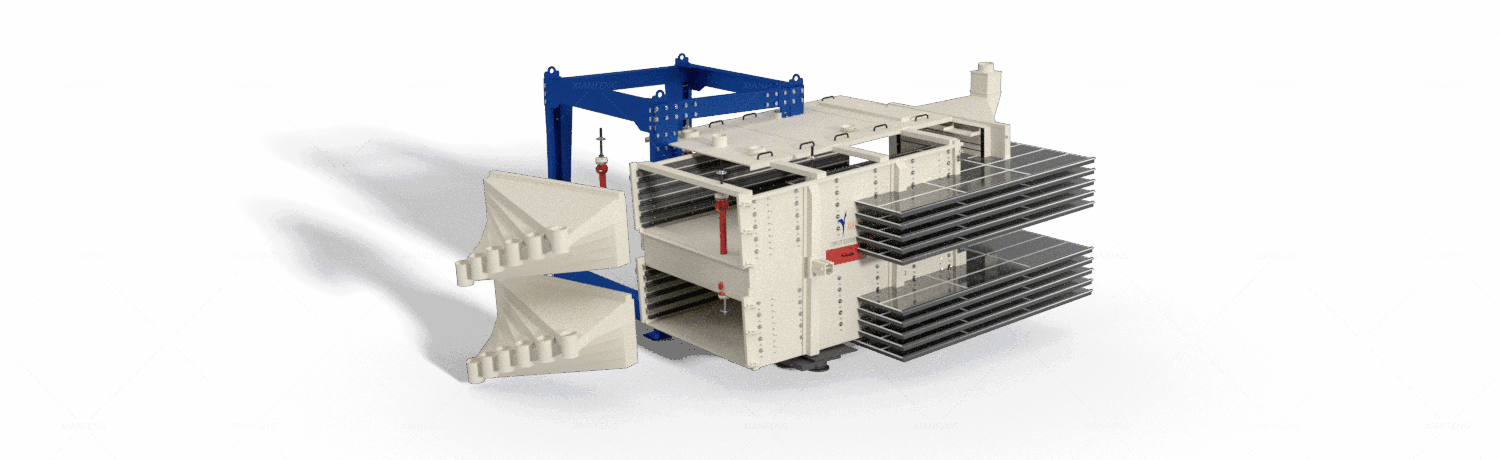

Made of Q235 thick high-strength carbon steel material, with high bolt riveting strength and a construction period of only 30 days. The surface is treated with electrostatic spraying or spray painting rust removal technology.

Carbon steel, stainless steel materials are optional. Coping with material scene screening in different industries, the inner wall is smooth without dead corners, the robotic arm automatically and accurately welds, seals well, and does not leak materials.

Imported Swiss ABB motor is used, with low power consumption, high efficiency, and low failure rate, effectively avoiding downtime and production line losses.

The rubber isolation on the surface of the screen frame prevents the screen mesh from sliding and wearing. XIAN FENG sieve plate adopts a unique wave pattern design, combined with high elasticity silicone elastic balls, which improves net cleaning efficiency by 30% and effectively increases production.

The mesh size of the screen mesh is precise, and the surface adhesive cloth strip process corresponds to the rubber of the screen frame, resulting in more uniform stress and greatly reducing wear. Combined with the hook plate design, two people can complete the screen replacement operation in 10 minutes.

Adopting a thick transmission shaft, it has high strength and no cracking, and runs smoothly in synchronous transmission.

Imported Swiss SKF bearings are used, which are oil-free for ten years. The exciter is oil free for life. Imported Japanese Tristar conveyor belt is adopted, which is free from deviation, slip and aging, and has a service life twice that of ordinary belts. Paired with Dutch Shell grease to ensure efficient operation of the production line.

Quartz sand screening

Mechanism sand screening

Screening of Fangyao Petroleum Fracturing Sand Production Line

Industrial salt screening production line

| Model | Screen layers | Power(kw) | Screen angle(°) | Rotation frequency(r/min) |

| FYBS1236 | 1-6 | 4 | 5 | 260-300 |

| FYBS1536 | 1-6 | 5.5 | 5 | 260-300 |

| FYBS2036 | 1-6 | 7.5 | 5 | 260-300 |

| 2FYBS1536 | 2-10 | 5.5-7.5 | 5 | 260-300 |

| 2FYBS2036 | 2-10 | 7.5-11 | 5 | 260-300 |

| 4FYBS2036 | 4-8 | 7.5-11 | 5 | 260-300 |

As of 2025, our square swing screen has undergone 5 technological iterations and obtained multiple national technical patent certifications. We have conducted detailed inspections on the square swing screen and have authoritative department issued inspection reports. The equipment uses imported motors and bearings to ensure smooth operation of the production line and avoid downtime. Our products have obtained CE and ISO related certificates, and we are a well-known large-scale source manufacturer in China. We have the strength to provide you with a complete set of customized screening and conveying production lines and supporting upstream and downstream equipment. From design to installation to after-sales service, there is no worry, and we support you or your partners to come to the factory for inspection at any time.

Yes, we can provide customized services based on your different material requirements, such as corrosive chemical materials or food materials. We recommend upgrading the screen body and frame to 304/316L stainless steel, and replacing the seals with fluororubber to meet different types of needs. And based on the layout of your production line and the actual situation of the site, we will tailor a solution for you, change the equipment height to match your production line, customize PLC linkage control automation production, explosion-proof function, etc. You can also send samples in advance for free machine testing, and we will show you the actual results of screening efficiency, accuracy, and impurity rate through video or live streaming.

The linear vibrating screen is mainly based on "linear trajectory (high-frequency small amplitude)", and the core difference between the two lies in "material movement mode and screening accuracy":

Square swinging screen: The material moves forward slowly along the screen surface, with a long residence time (10-30 seconds), suitable for high-precision grading (such as particle size error ± 5 μ m);

Linear vibrating screen: The material rushes rapidly in a straight line along the screen surface, with a short residence time (3-10 seconds), suitable for rapid impurity removal (such as removing a small amount of coarse slag from the material), but with low accuracy.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.