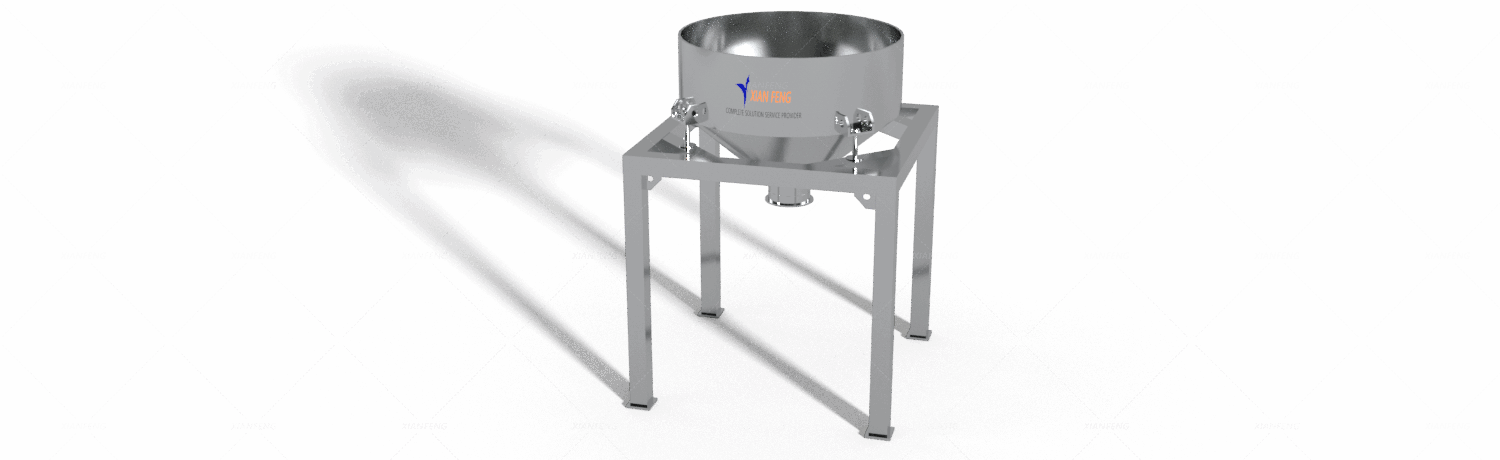

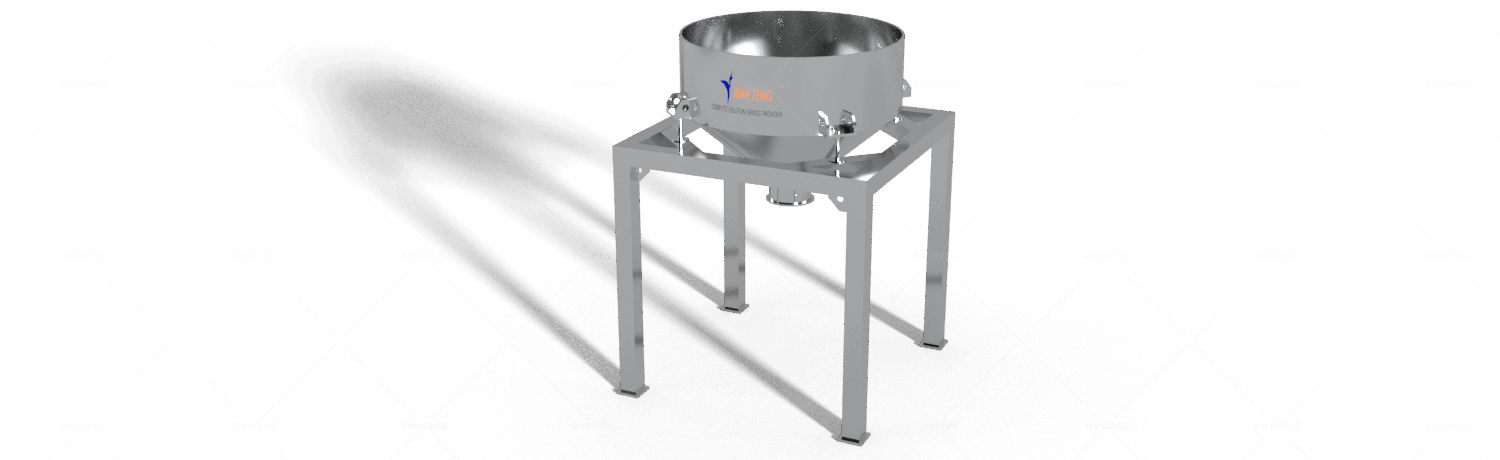

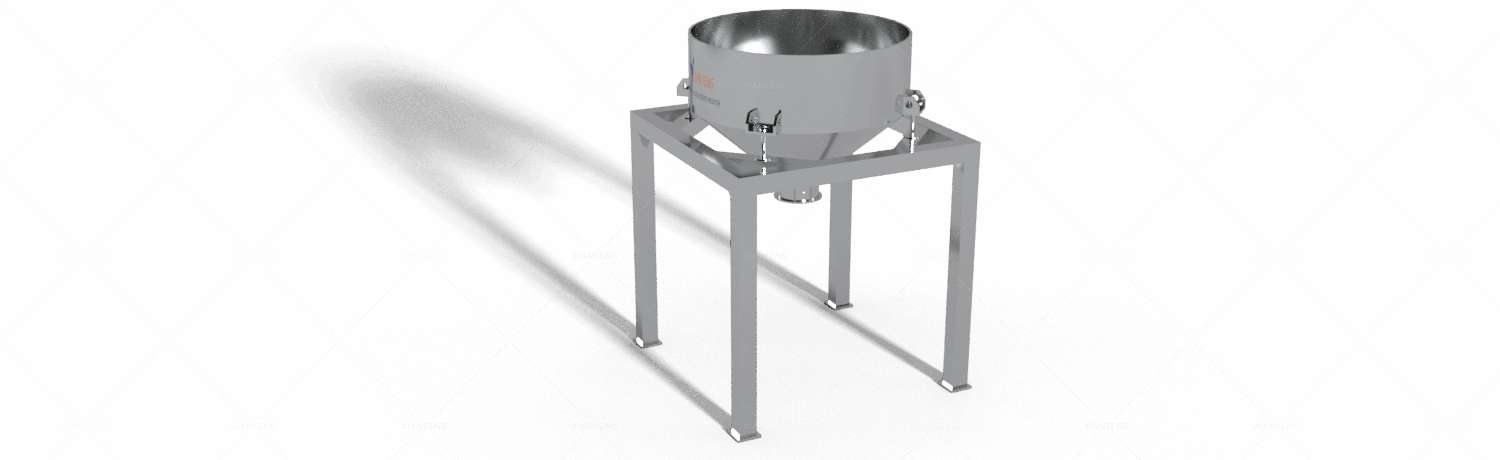

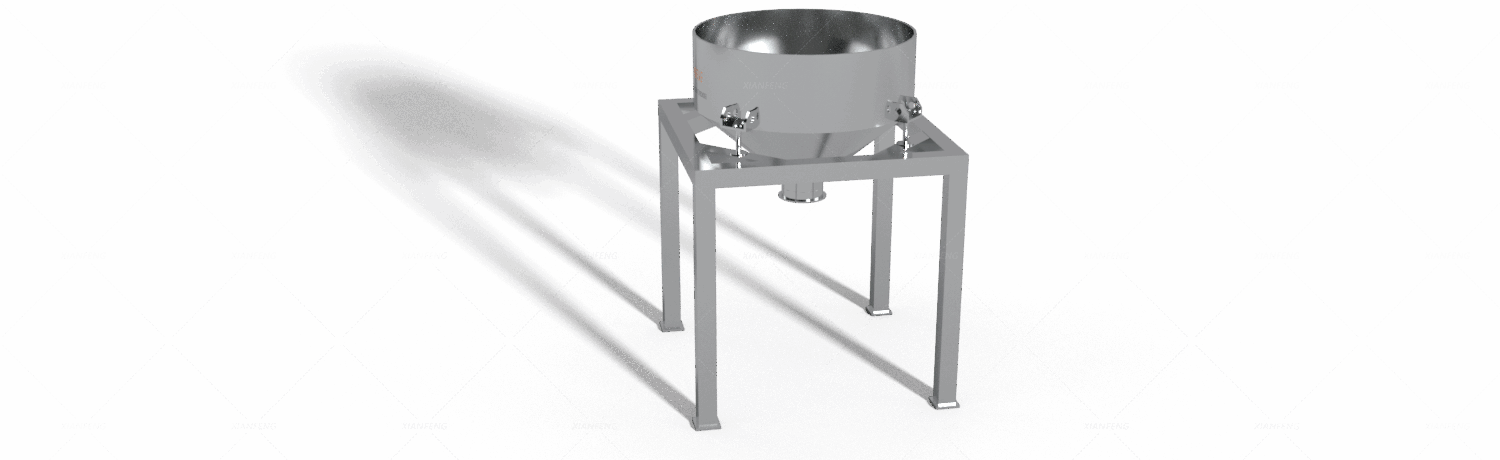

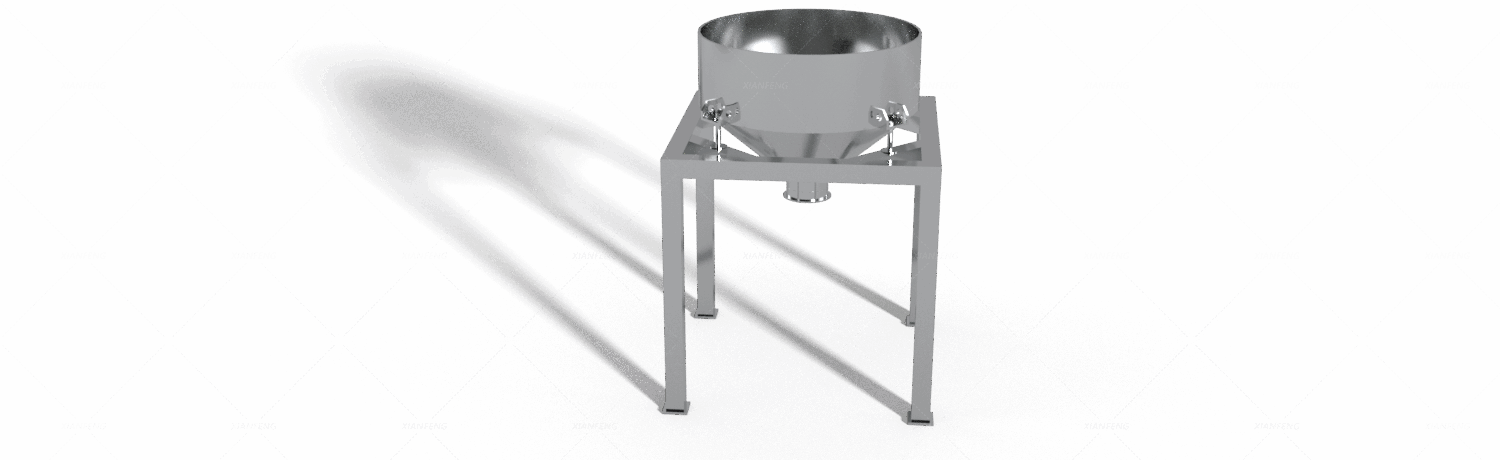

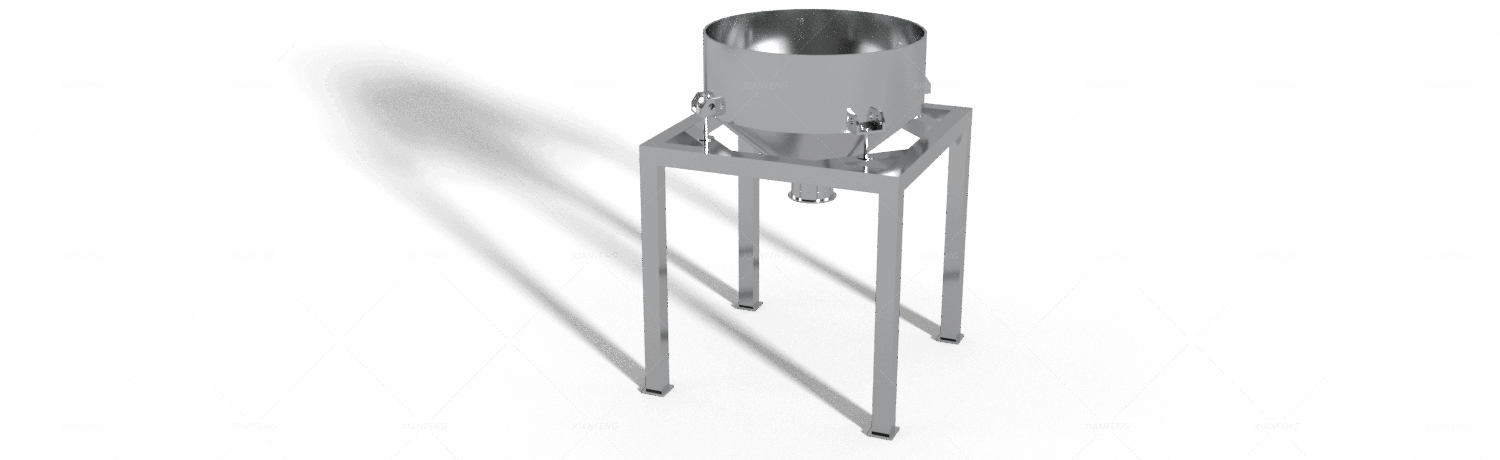

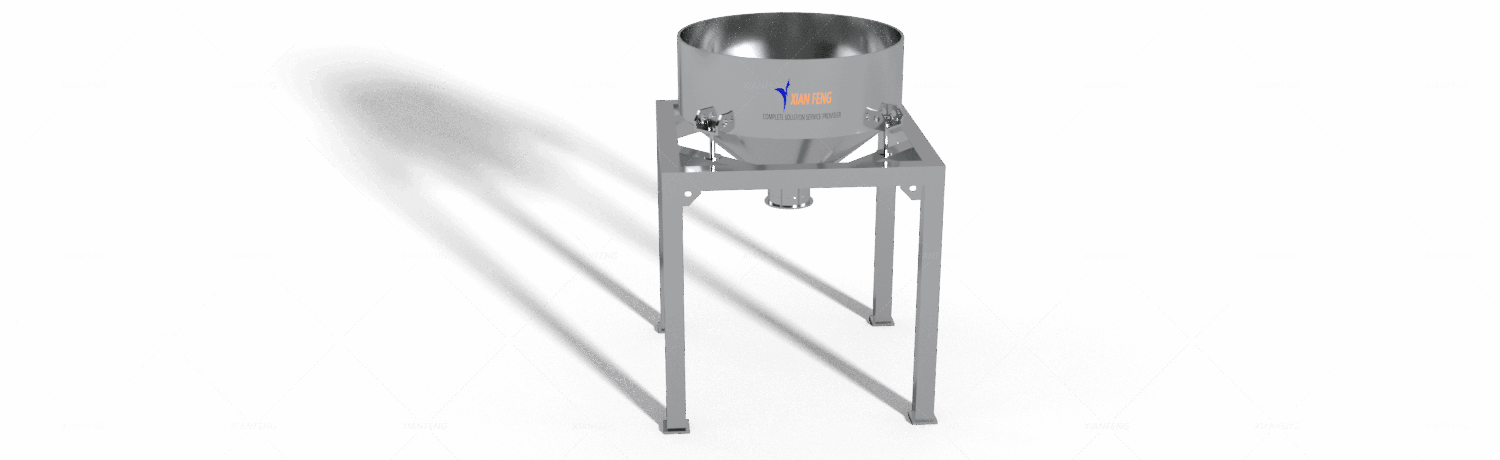

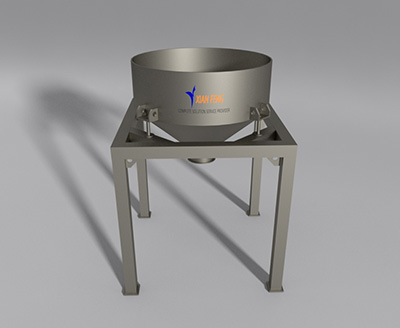

The silo is a key auxiliary equipment that connects the upstream material storage/transportation link with the downstream vibrating screen screening link. Its core function is to achieve "buffer temporary storage" and "stable feeding" of materials, avoiding the decrease in screening efficiency and equipment damage caused by upstream feeding fluctuations (such as material breakage and overload) of the vibrating screen, while coordinating the material flow rhythm of the entire production line. Widely applicable, can be customized according to different industries such as food, pharmaceuticals, chemicals, mining and metallurgy, metal powders, etc.

Flour, powdered sugar, milk powder, fruit juice, nuts, tea, dried flowers, pet food, etc.

Pills, pills, powders, capsules, intermediates, excipients, etc

Coatings, hydrochloric acid, resin particles, fluorescent powder, nitric acid, sodium hydroxide, sodium carbonate, etc

Coal, quartz sand, lime powder, cement powder, dry sand, soil, glass, talcum powder, etc

Iron powder, copper powder, aluminum powder, tungsten powder, titanium powder, nickel powder, zinc powder, etc

Surface treatment process

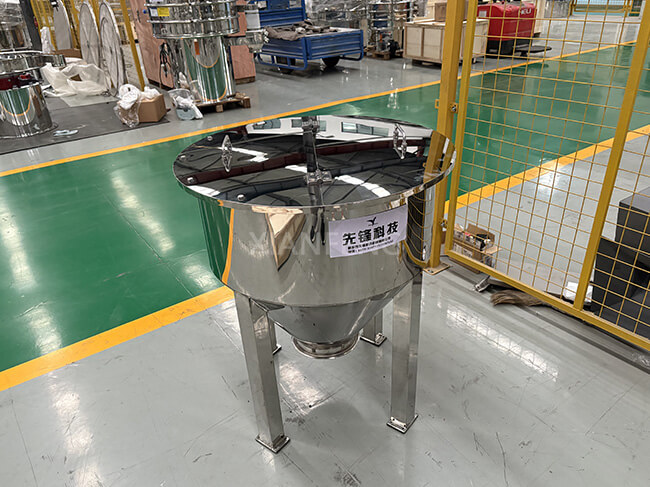

Inside the silo

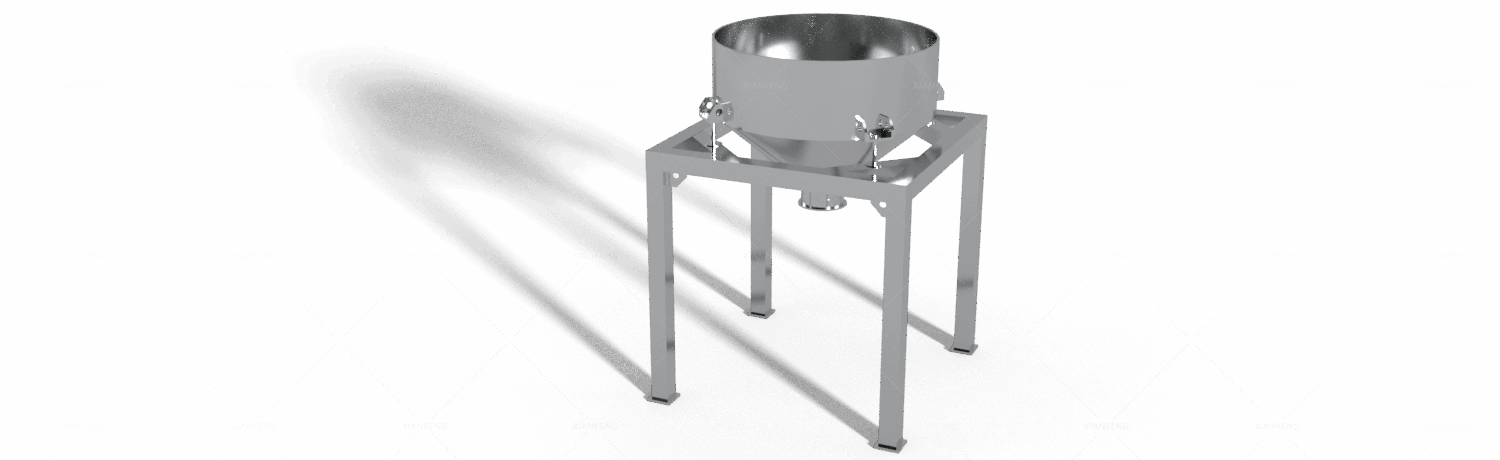

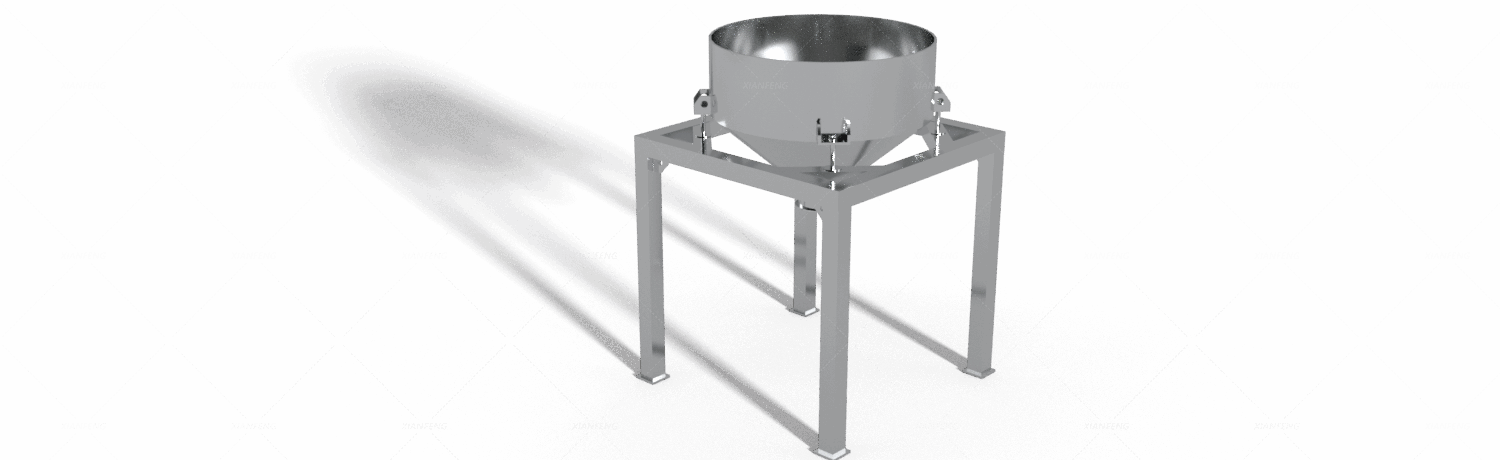

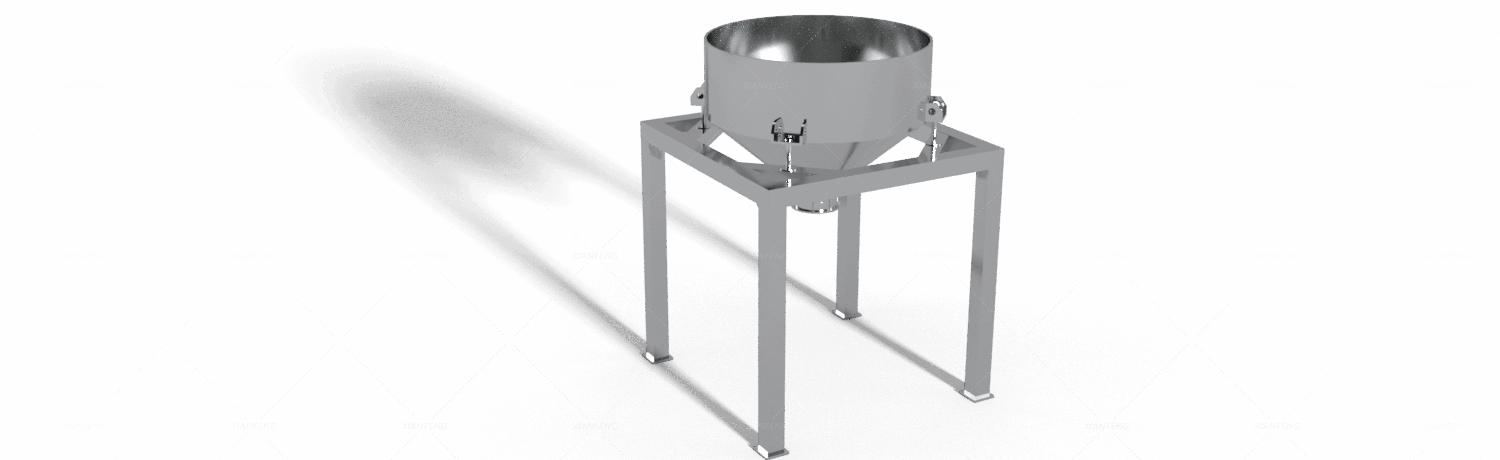

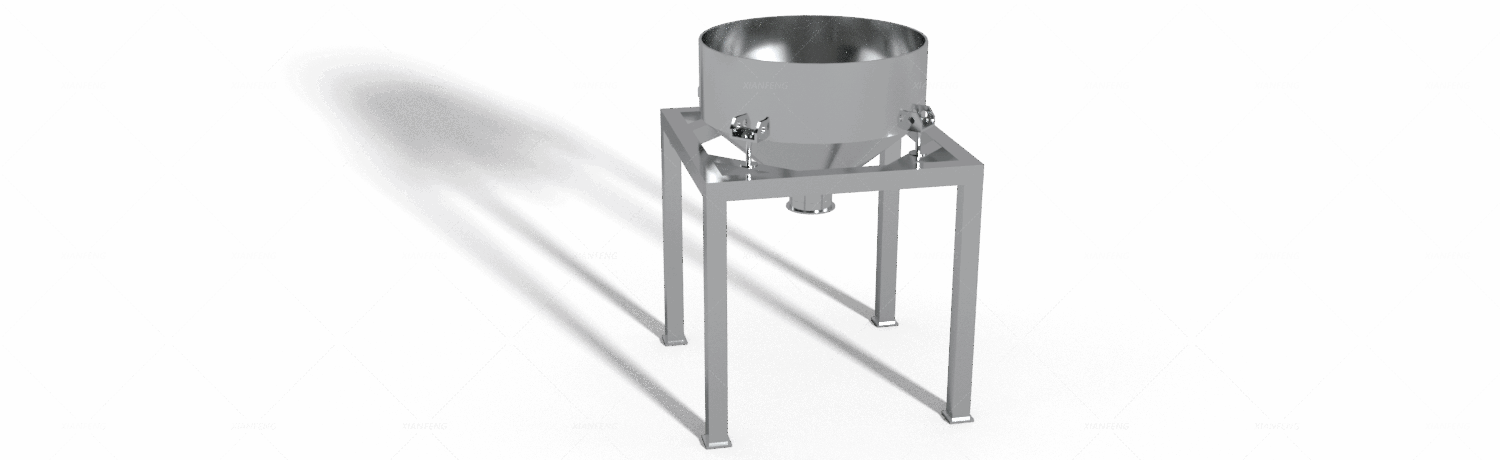

Fixed and functional

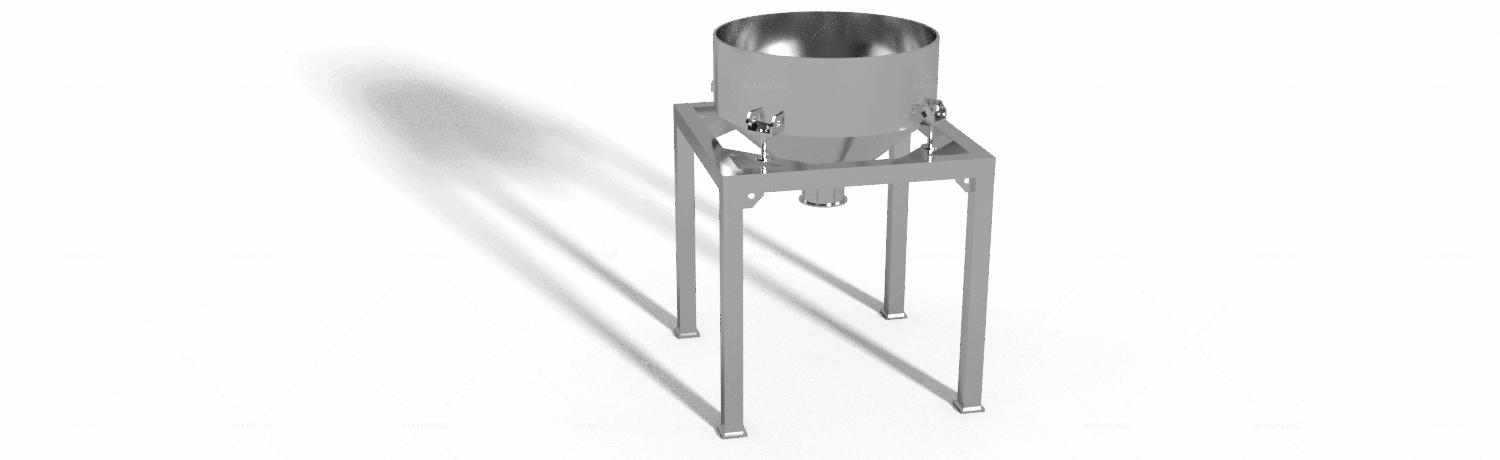

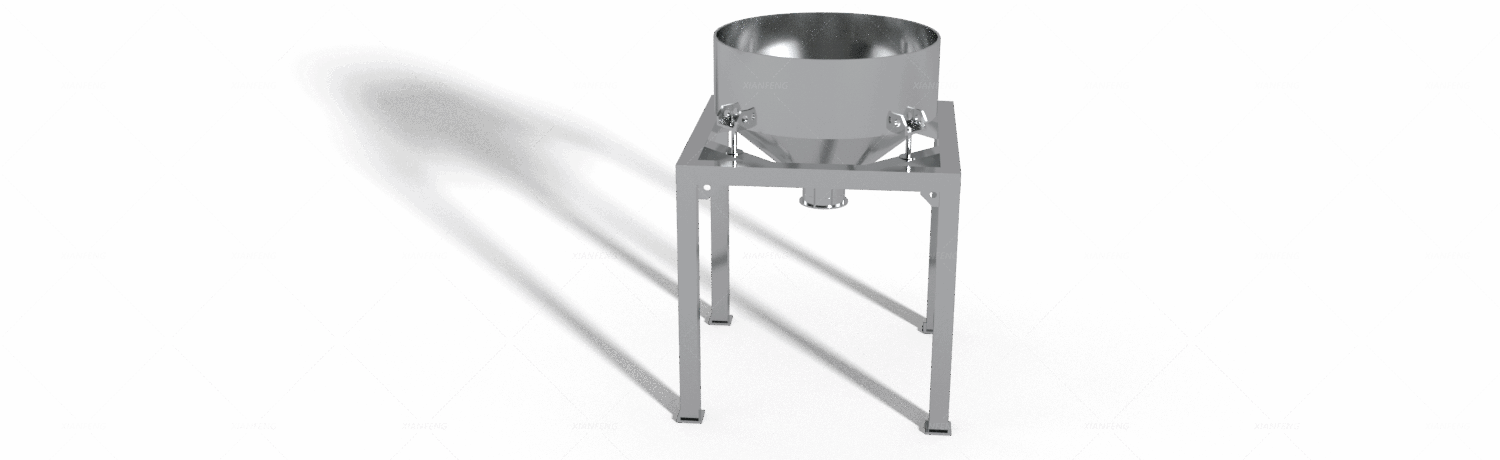

Discharge outlet

Base

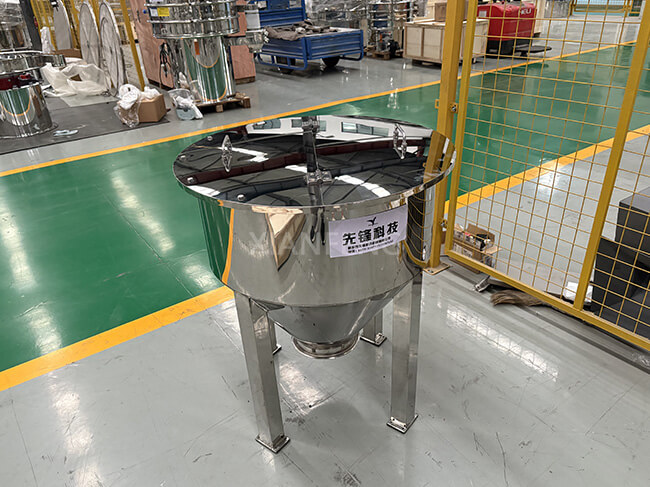

We can customize surface treatment processes such as sandblasting, polishing, and wire drawing according to customers

The silo can be customized with single-layer or double-layer structure according to customer needs

Choose split bolt fixation or integral welding method according to actual needs.

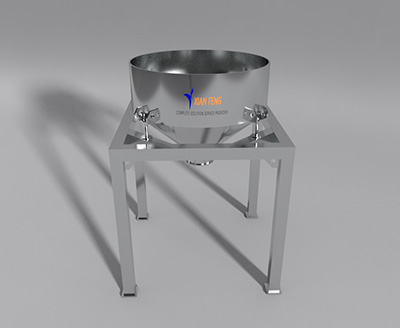

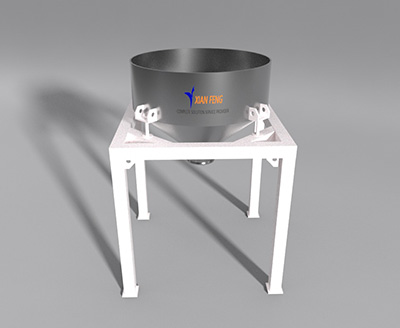

The discharge port can be matched with various types of connecting accessories to adapt to various upstream and downstream equipment. For example, manual butterfly valves, rotary flip valves, suction adapters, flanges, or directly linked screw conveyors can meet different production needs.

Different support methods can be customized according to the weight of the silo to meet different load-bearing requirements.

The core working principle of the silo is to achieve temporary storage, uniform feeding, and anti clogging control of materials through gravity flow and mechanical assistance. The material flows from the top of the warehouse to the bottom discharge port by gravity, and the inclination angle of the warehouse wall (usually ≥ 55 °) and smooth material (such as stainless steel) can reduce friction and prevent adhesion. To deal with viscous or agglomerated materials, arch breaking devices such as vibrators are often equipped, or flow patterns are changed by built-in modified fluids (such as conical baffles) to convert inefficient "funnel flow" into efficient "integral flow", ensuring continuous and stable discharge of materials. Flow control is achieved through manual/pneumatic valve adjustment of opening, combined with level sensors and PLC control systems to achieve automated start stop and precise feeding. This composite mechanism is widely used in industries such as chemical, mining, and food. When combined with vibratory separators, conveyors, etc., the structure and parameters can be flexibly adjusted according to material characteristics (particle size, humidity) to meet personalized production needs..

dust cover, screen frame, screen mesh, cleaning elastic ball, punching tray, tie ring, spring, vertical motor, and base.

Its main function is to prevent internal materials or dust from overflowing during feeding. It can be

Shaped by a high-precision coiling machine and welded with fish scale patterns to ensure strength, it ensures no looseness, deformation, or cracking under high-frequency vibration, and efficient transmission vibration ensures screening efficiency.

Made of 304/316 stainless steel, with precise mesh holes.

Made of rubber/silicone material to meet various material requirements, ensuring elasticity, durability, and preventing damage, powder loss, and material contamination.

made of high-strength steel material, with rounded and polished material that does not adhere during cutting.

V-shaped is used for connecting and interlocking components such as screen frames, with high quality and no vibration cracking. Bolts or quick opening structures are optional.

High load-bearing, high elasticity spring, efficient shock absorption and wear resistance.

Imported Ouli Wolong motor is used, with high amplitude and low power, which is more energy-efficient. Explosion proof motor can be selected to meet special needs.

The unique high-strength steel cone design evenly distributes the vibration force to the screen frame and screen surface, reducing energy loss and improving screening efficiency.

Rigid support to resist resonance, built-in optimized shock absorption structure to reduce ground impact and ensure equipment safety.

The silo used with a vibrating screen is designed to ensure efficient and stable operation. These functions primarily include three key aspects:

Buffering and temporary storage to eliminate feed fluctuations

Upstream feeders (such as conveyor belts and elevators) often experience intermittent or unstable flow rates (e.g., ore delivery in mines). A silo can temporarily store a certain amount of material. When the upstream feed is insufficient, the silo can be replenished; when the upstream feed is excessive, the silo can be used to temporarily store material, preventing the vibrating screen from running idle or overloading and blocking the screen.

Stable feed to match the screen's capacity

The screening efficiency of a vibrating screen depends on a uniform and continuous feed rate. If the feed rate fluctuates, screening may be incomplete at best, or material may accumulate on the screen surface and clog the meshes at worst. The silo delivers material to the vibrating screen's inlet at a constant flow rate through a bottom-mounted feed structure (such as a star discharger or screw feeder), ensuring the feed rate perfectly matches the screen's rated capacity. Pre-treatment Assistance Optimizes Screening Performance

For materials prone to agglomeration and high moisture content (such as pulverized coal and clay), some silos are equipped with integrated arch-breaking devices (such as pneumatic arch-breaking or vibration arch-breaking) or pre-dispersion mechanisms to preemptively break up material agglomerates and disperse material clumps. This prevents agglomerated materials from entering the vibrating screen and clogging the screen apertures, reducing screening efficiency.

You can categorize materials based on "material properties + screening requirements." Materials from different industries (such as ores, chemical powders, and food granules) have significantly different characteristics, and vibrating screens have different screening requirements. Therefore, supporting silos need to be designed according to their type. Common types are as follows:

1. Classification by Material: Adapting to Material Corrosiveness/Hygiene Requirements

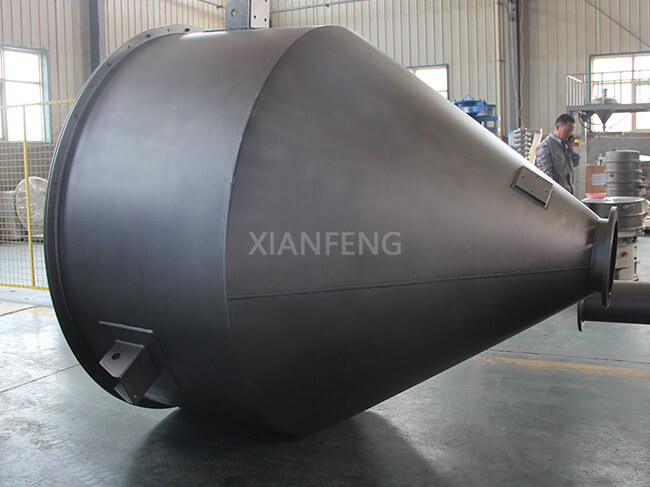

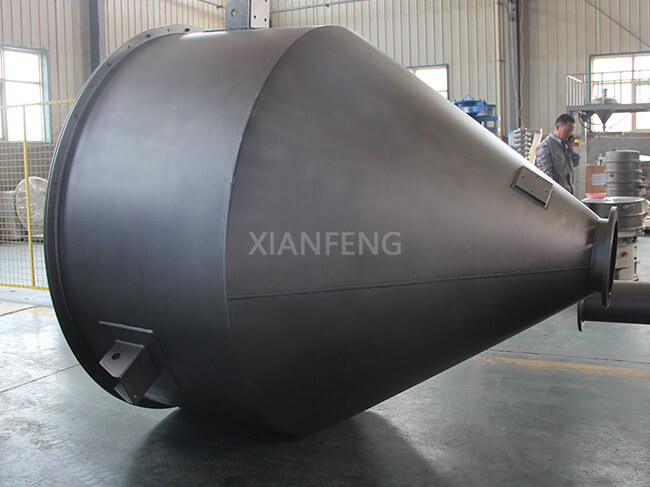

Carbon Steel Silos: Low cost and high strength. Suitable for non-corrosive materials with no hygienic requirements, such as mining ores and construction sand and gravel, and paired with heavy-duty vibrating screens.

Stainless Steel Silos (304/316L): Highly corrosion-resistant and easy to clean. Suitable for industries such as food (e.g., flour and grain), pharmaceuticals (e.g., powdered drugs), and chemicals (e.g., acid and alkali granules). Paired with sanitary or corrosion-resistant vibrating screens.

2. Classification by Structural Type: Adapting to Site and Material Flow

Cylindrical Silos: Uniform wall stress and good material flow (prevents accumulation). Suitable for highly fluid granular materials (e.g., plastic granules). Paired with small and medium-sized vibrating screens, they occupy a small footprint. Square/Rectangular Silos: These facilitate multiple material discharges (can be connected to multiple vibrating screens simultaneously) and are suitable for production lines requiring multiple screens in parallel (such as grading and screening in the chemical industry). However, corners are prone to material accumulation, requiring additional arch-breaking devices.

3. Classification by Function: Adapting to the Core Needs of Vibrating Screens

Buffer Silos: Their core functions are "temporary storage and flow stabilization." They have a smaller capacity (typically equivalent to a vibrating screen's processing capacity for 10-20 minutes) and are suitable for situations with large upstream material fluctuations (such as intermittent feeding), ensuring continuous vibrating screen operation.

Metering Silos: Integrated weighing modules (such as belt scales or load cells) enable precise control of feed rate (e.g., 500 kg per hour). They are suitable for applications requiring high screening accuracy (such as precise batching and screening in the pharmaceutical industry).

Heating/Cooling Silos: For materials requiring temperature control (such as hot-melt plastic pellets and high-temperature slag), the silo is equipped with heating or cooling interlayers to regulate the material temperature before entering the vibrating screen, preventing high-temperature damage to the screen mesh or low-temperature agglomeration.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.