A vacuum conveyor is a type of vacuum conveying system that uses negative pressure vacuum power to achieve dust-free conveying and feeding of dry materials such as powders or particles throughout the entire process. It has two power sources: pneumatic and electric, and is divided into intermittent and continuous types to meet different production needs. It can meet explosion-proof conveying scenarios and is widely used in the food, pharmaceutical, chemical, and new materials industries. It can be applied to various industrial production lines in conjunction with vibrating sifters.

raw material powders such as amoxicillin powder, cephalosporin powder, vitamins; Medicinal excipients such as lactose powder, microcrystalline cellulose, dextrin, etc

wheat flour, flour, skimmed milk powder, biscuit powder, nut fragments, glucose powder, sugar, potassium sorbate, refined flavor powder, etc

PE (polyethylene) particles, PP (polypropylene) particles, natural rubber powder, styrene butadiene rubber particles, carbon black powder, titanium dioxide, fertilizers, catalysts, etc

ternary material powder, lithium iron phosphate, graphite powder, polycrystalline silicon powder, lithium salt powder, soda ash powder, electrolyte additive powder, etc

calcium carbonate powder, aluminum powder, coke powder, limestone powder, fluorite powder, cement, gypsum powder, talc powder, resin powder, etc

Pipe Material

Filter element and discharge valve

Bracket

Control Panel

Material

Power Type

The general material for pipelines is flexible materials such as silicone or PU, and stainless steel material can also be customized to meet different production environment requirements.

Conventional filter cartridges are made of materials such as PP, PE, polyester fiber, stainless steel, titanium metal, etc., to meet different production needs.

The unloading method usually uses flip butterfly valves, star shaped unloaders, or customized auxiliary equipment for different scenarios.

Fixed brackets can be customized according to different production needs to meet the requirements of different production environments.

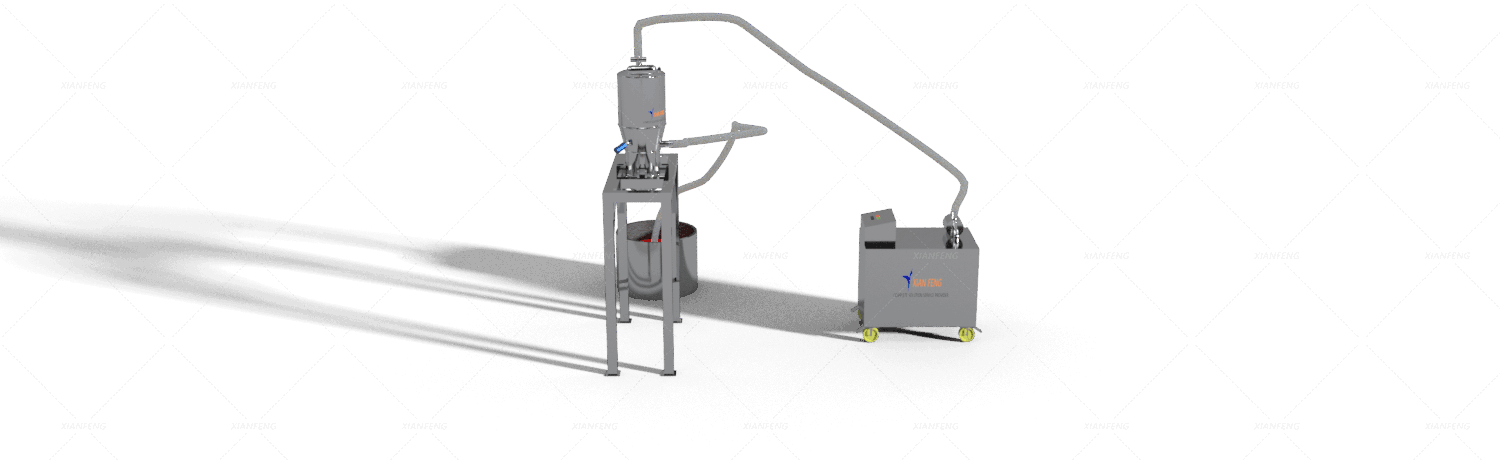

Pneumatic vacuum feeders generally use a simple basic panel, with a single core function of controlling ventilation and power-off, and simple setting of work cycles.

Electric vacuum feeders generally use more advanced intelligent control panels, based on PLC or dedicated microcontrollers, with rich control functions. They can not only monitor the suction status, but also customize functions such as automatic alarm, material level control, or production line automation control.

Made of 304/316 stainless steel material, acid and alkali resistant, and corrosion-resistant.

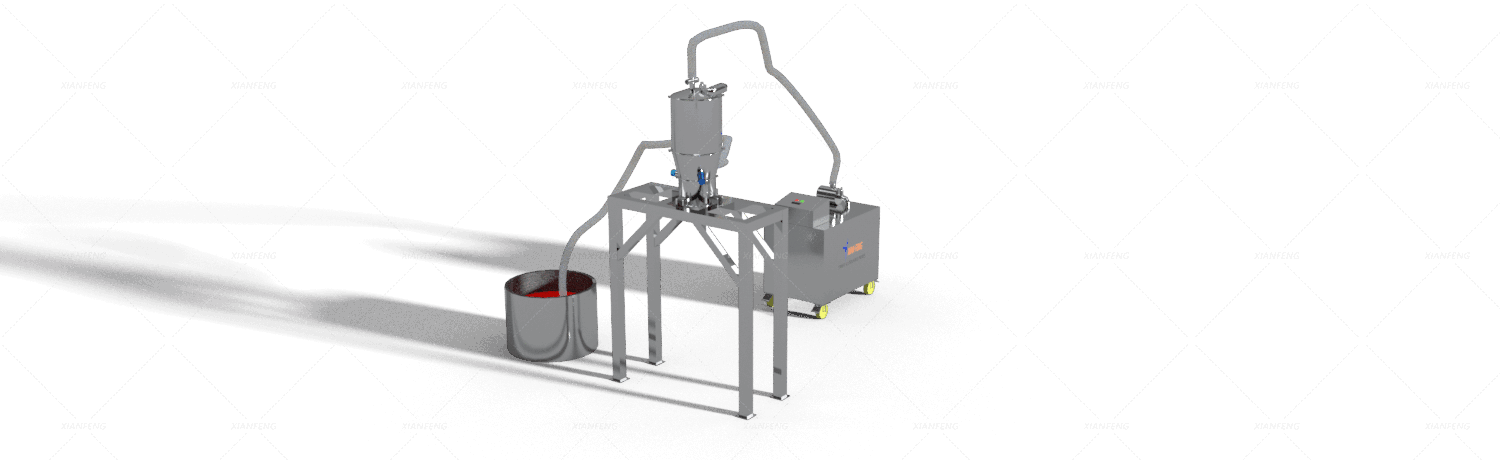

It is mainly divided into two power sources: electric and pneumatic. Electric drives the fan, which generates negative pressure through the rotation of the fan, realizing the vacuum suction and conveying of materials, and can operate continuously. Pneumatic uses a pneumatic motor to drive the impeller for material conveying, which is more suitable for intermittent material conveying due to its pneumatic characteristics

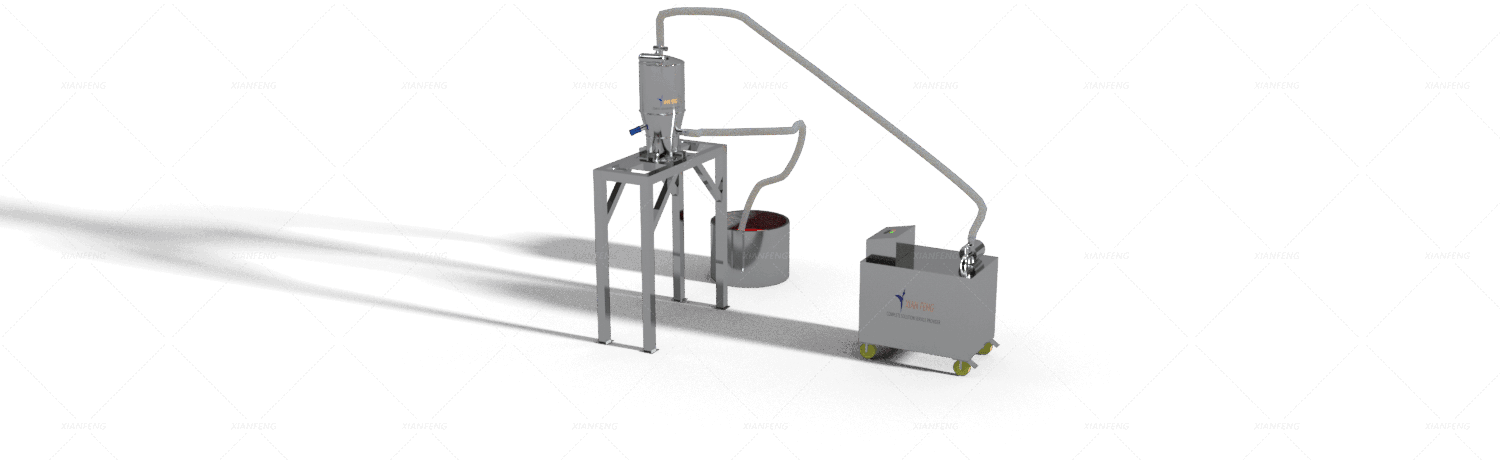

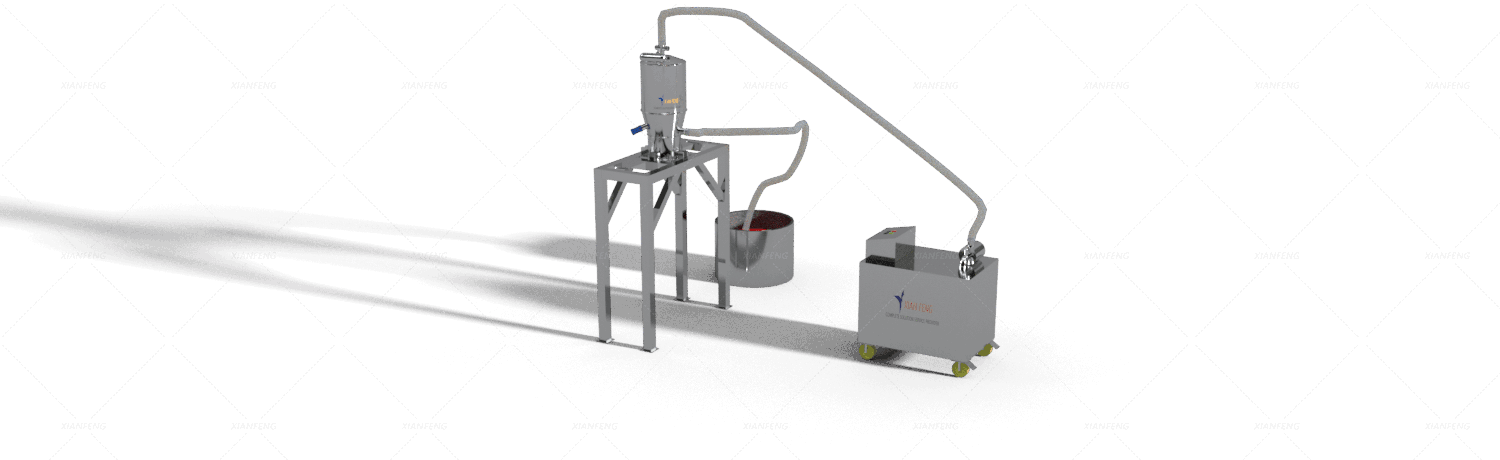

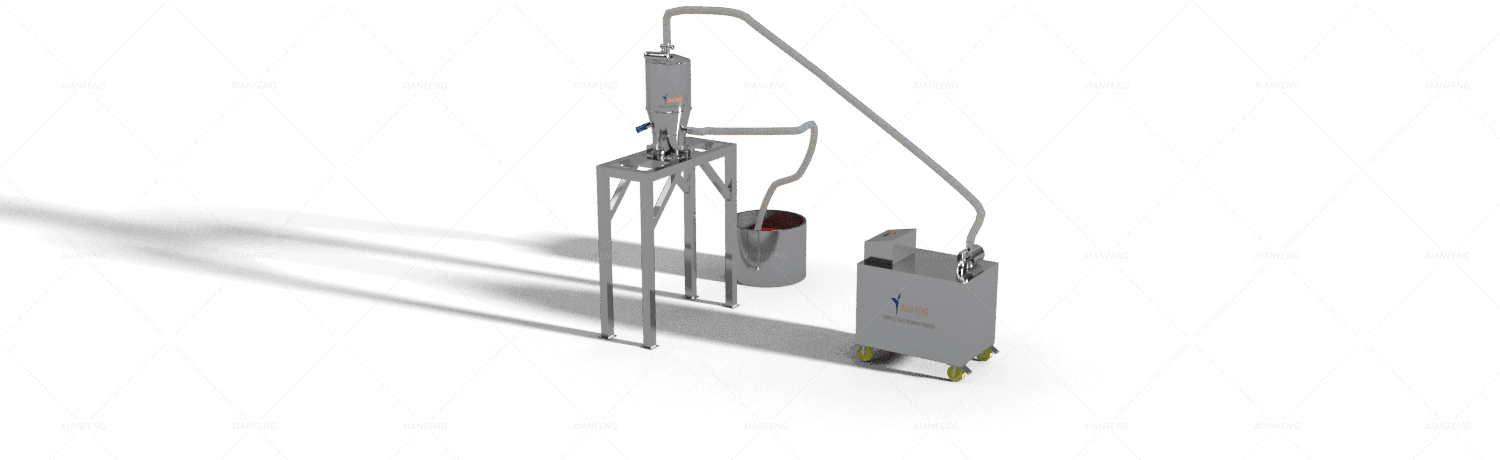

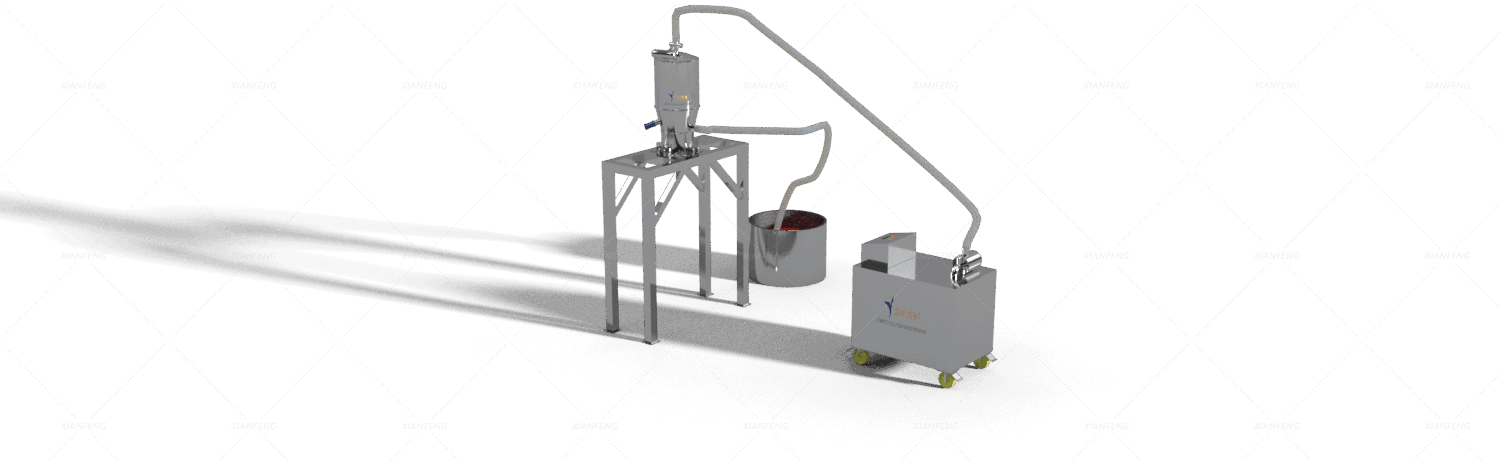

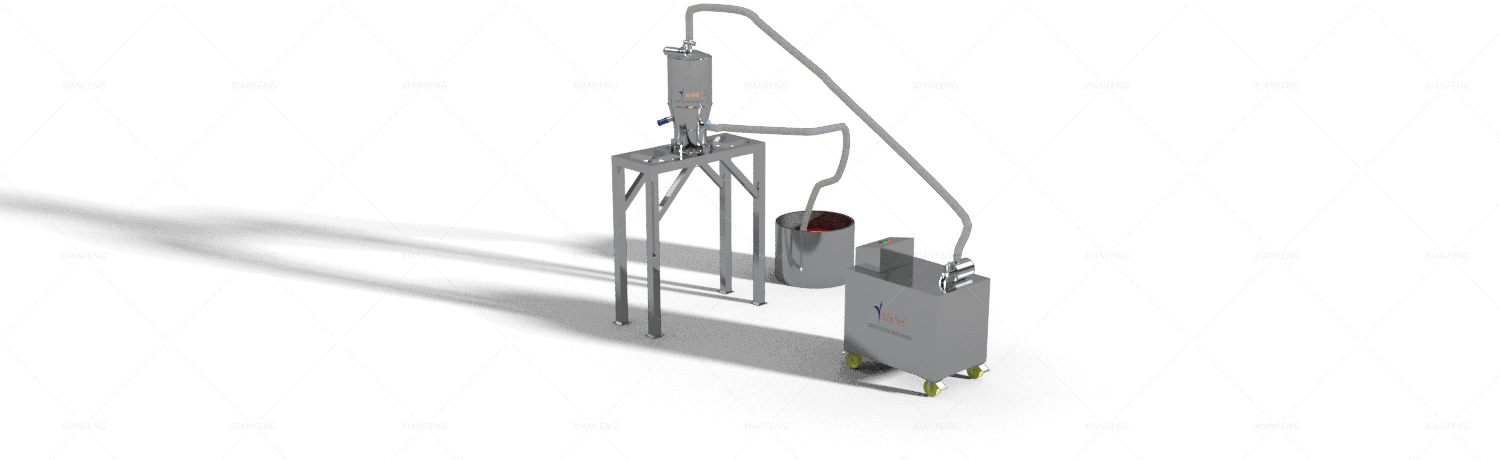

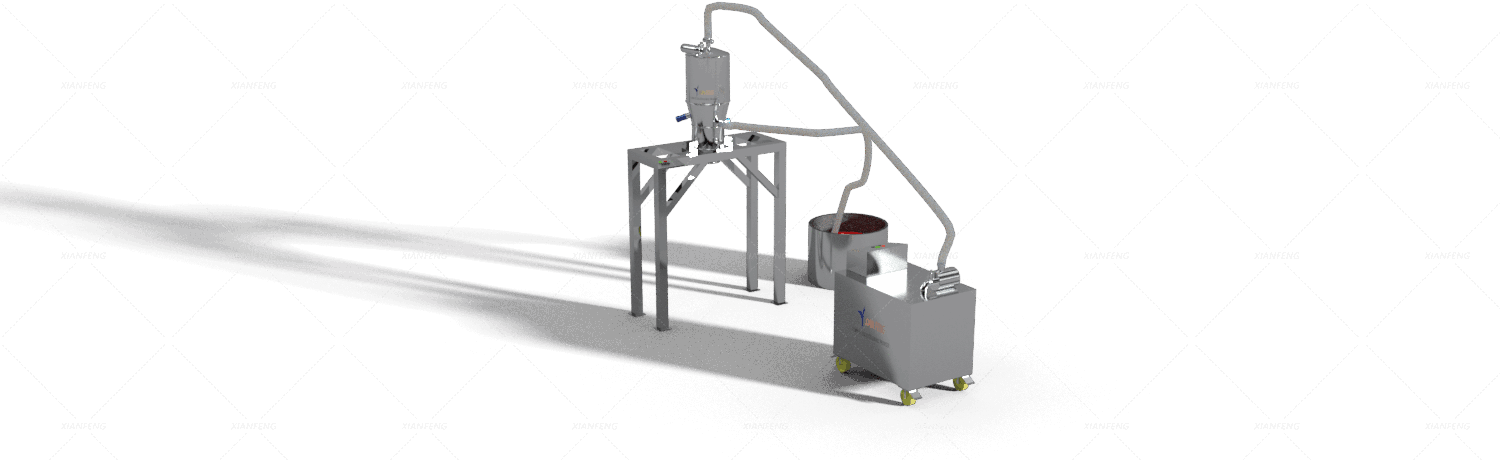

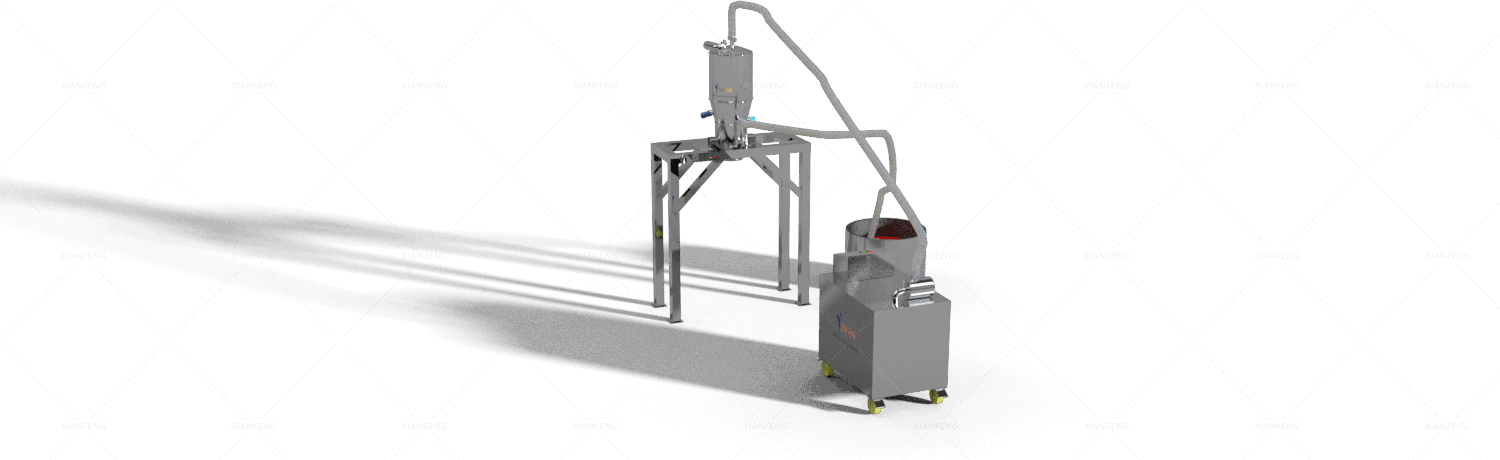

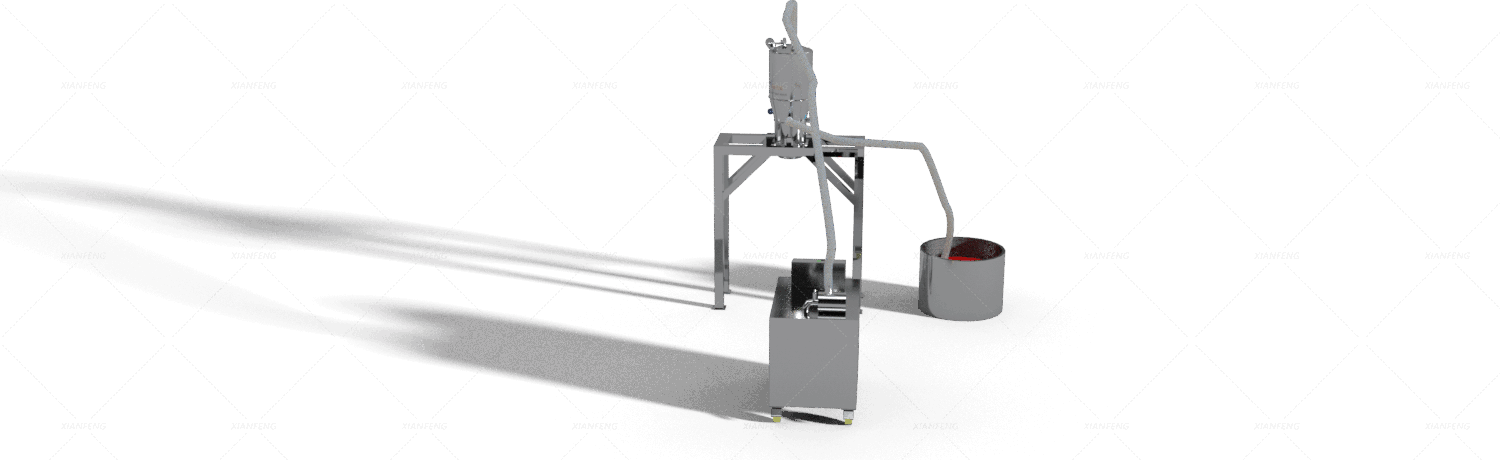

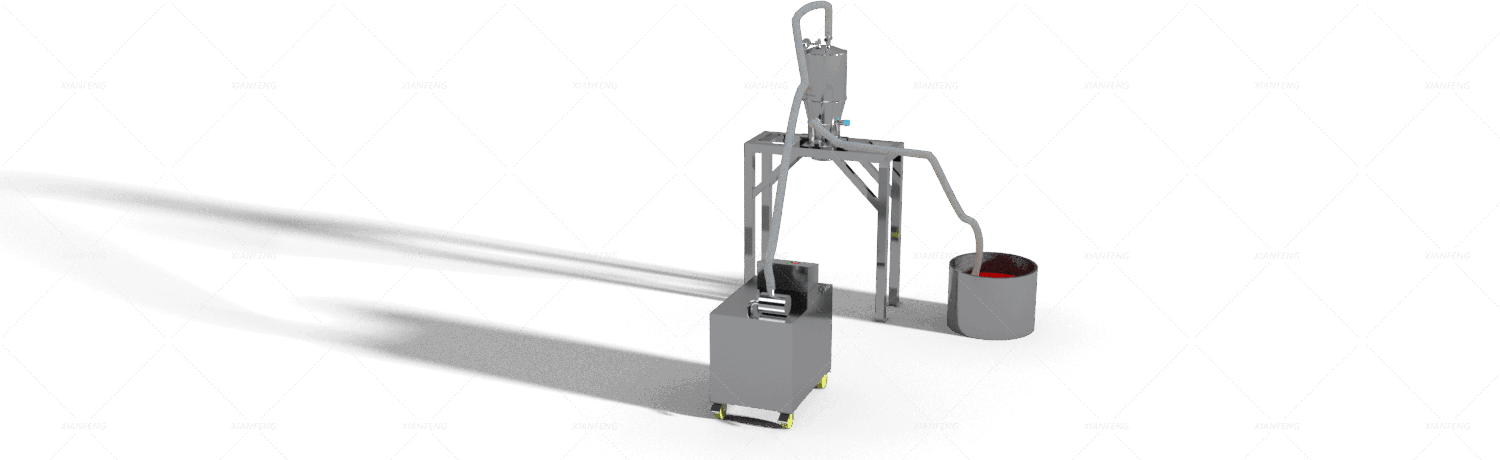

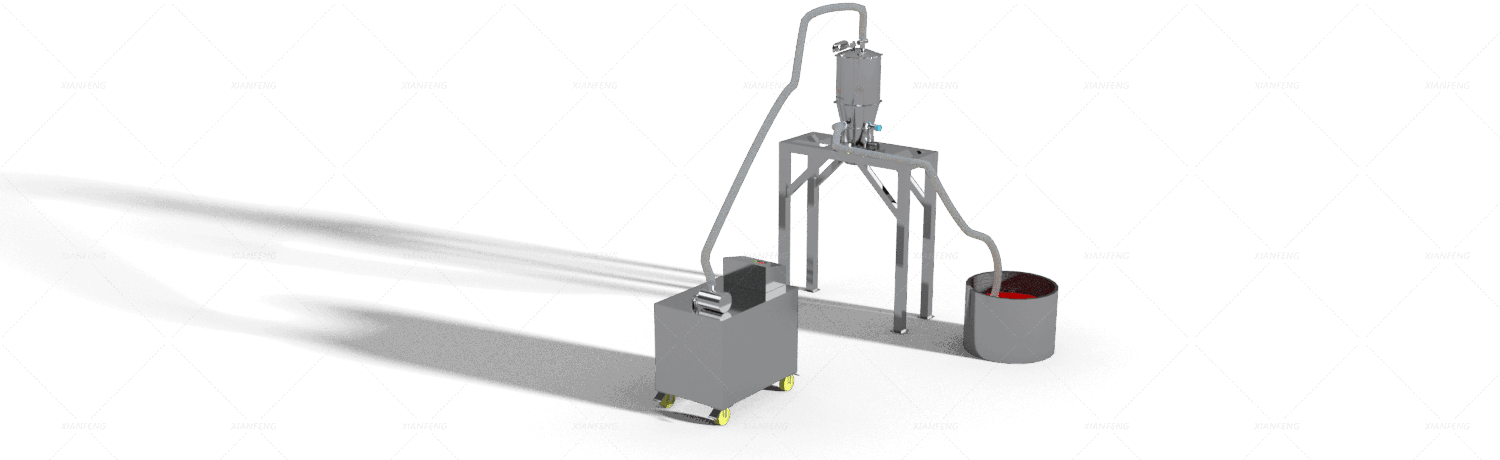

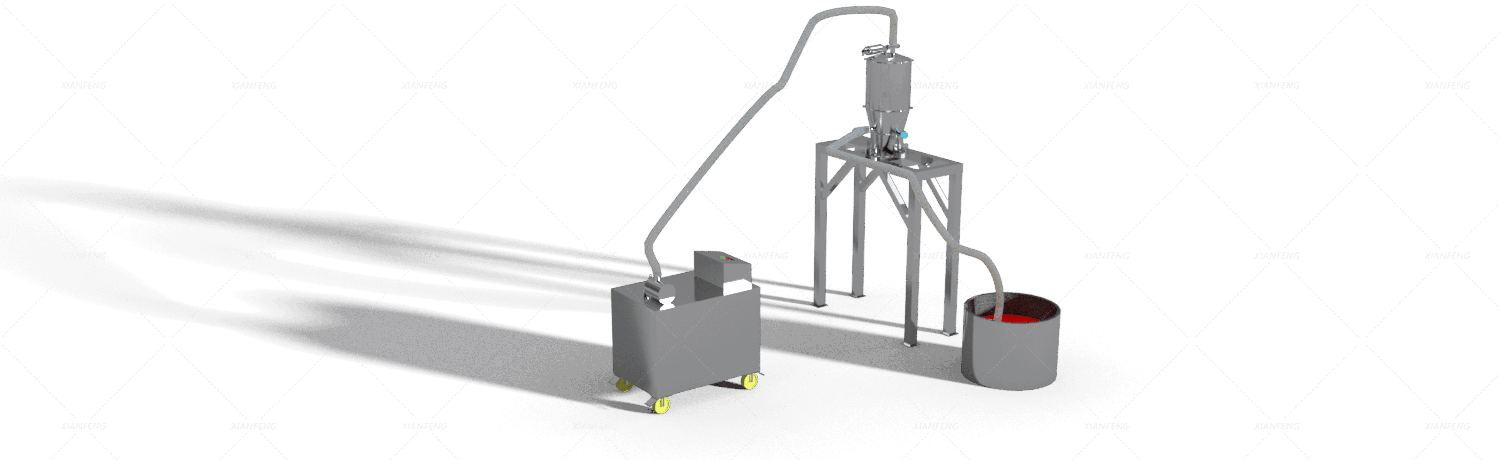

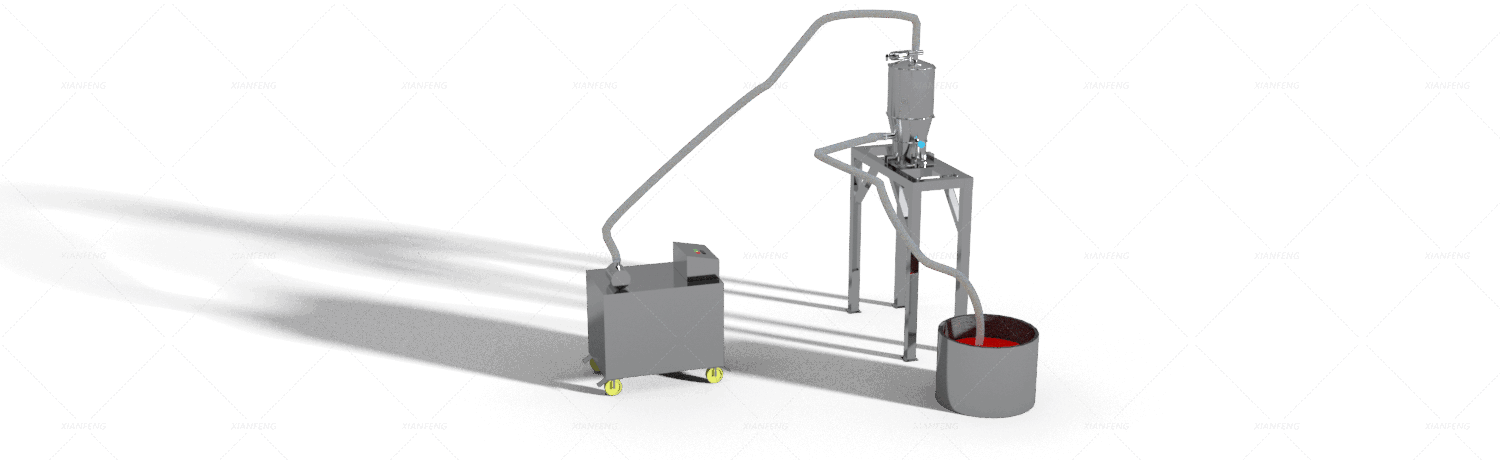

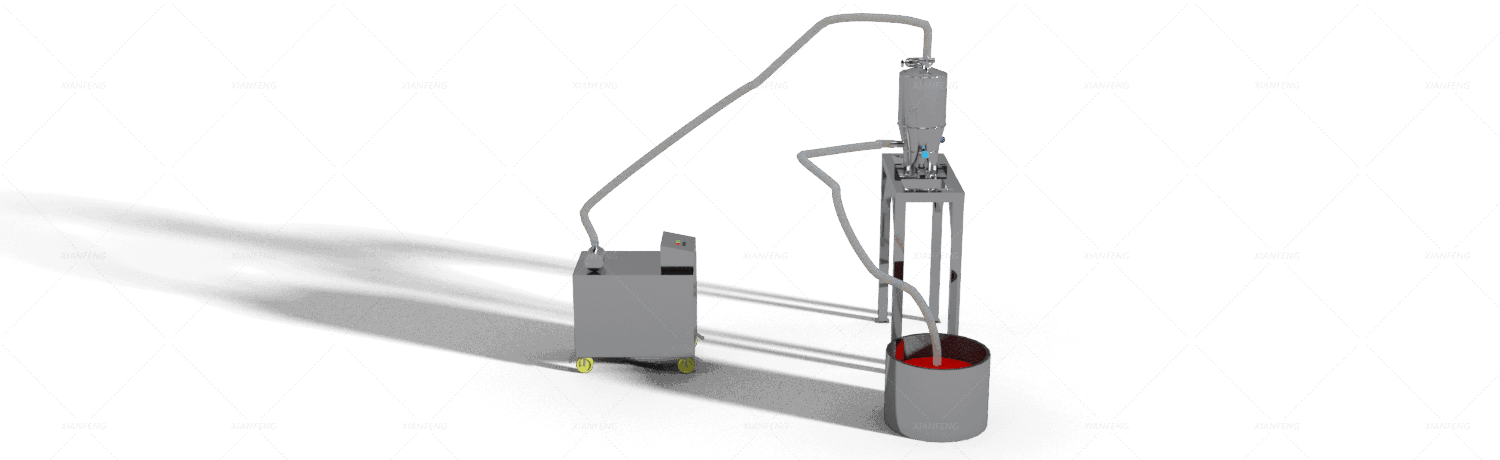

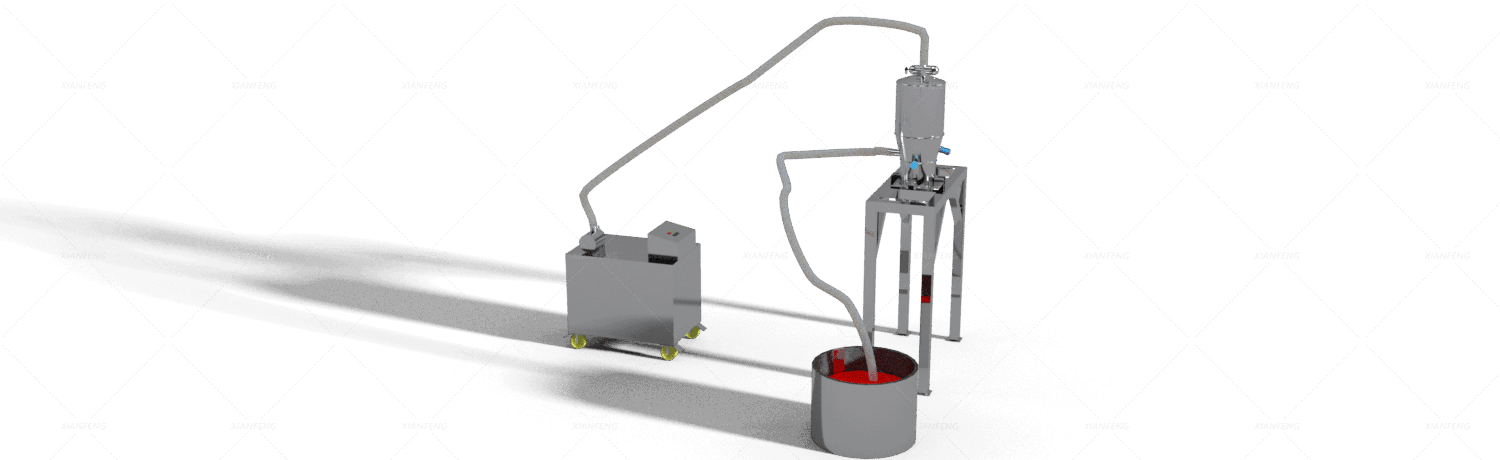

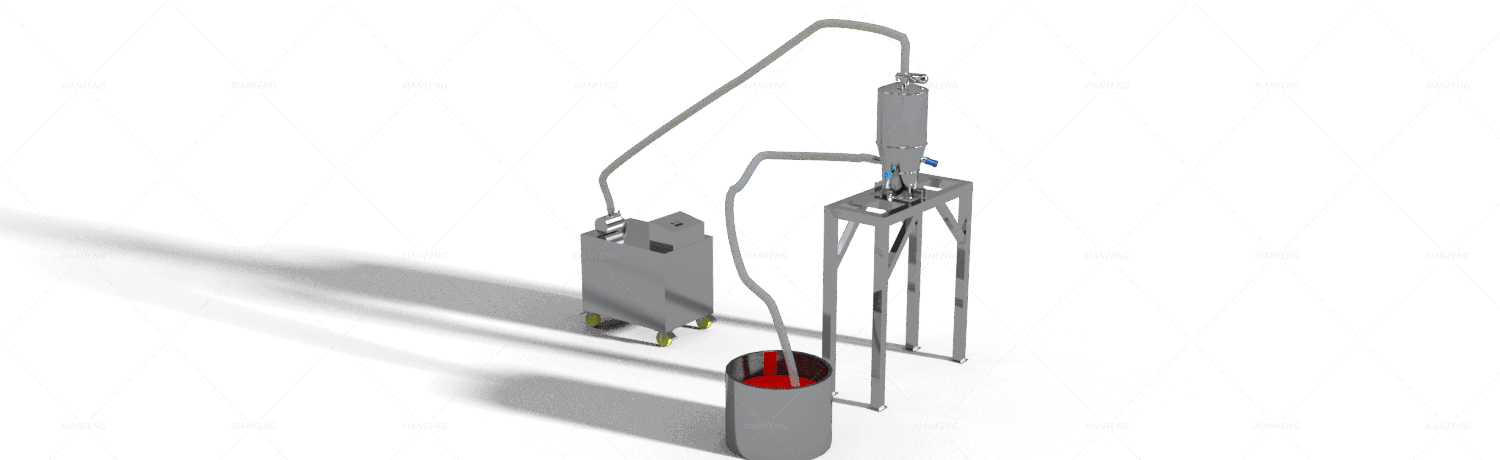

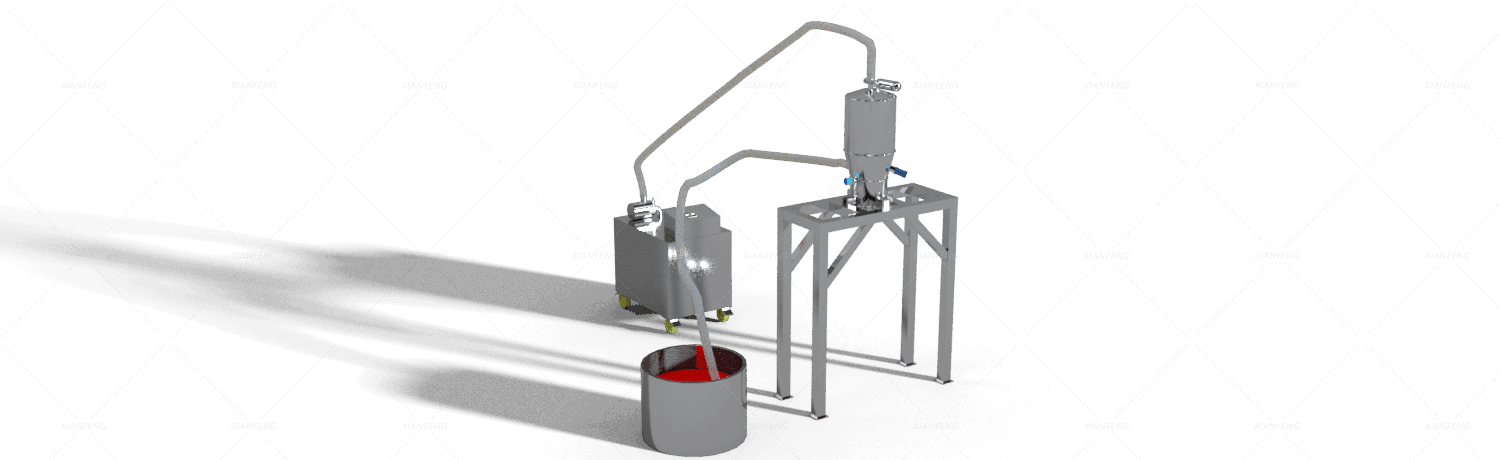

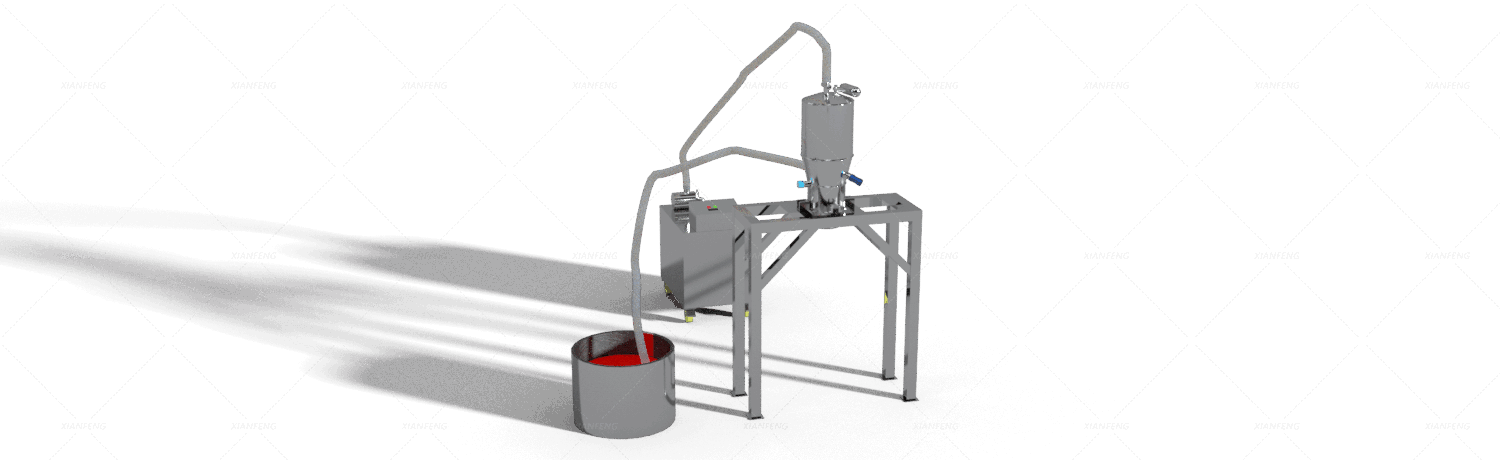

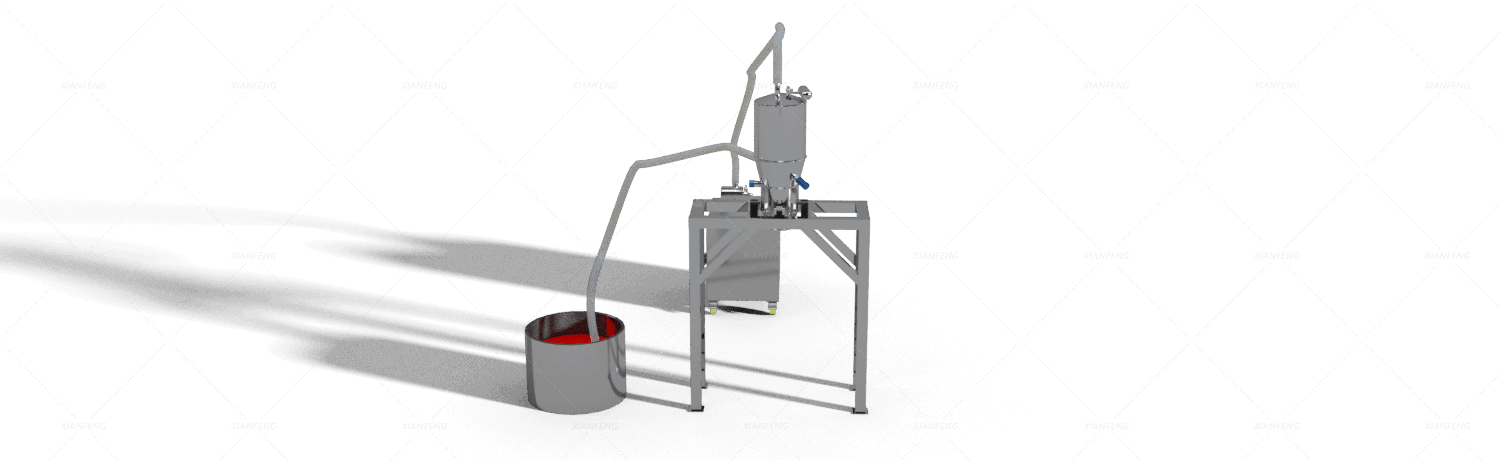

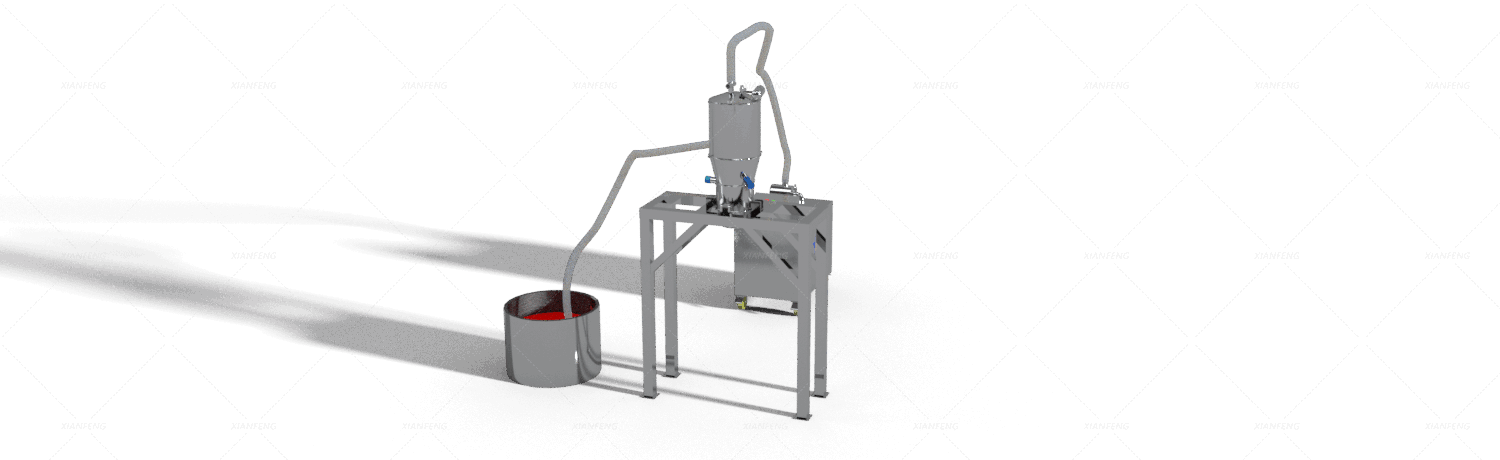

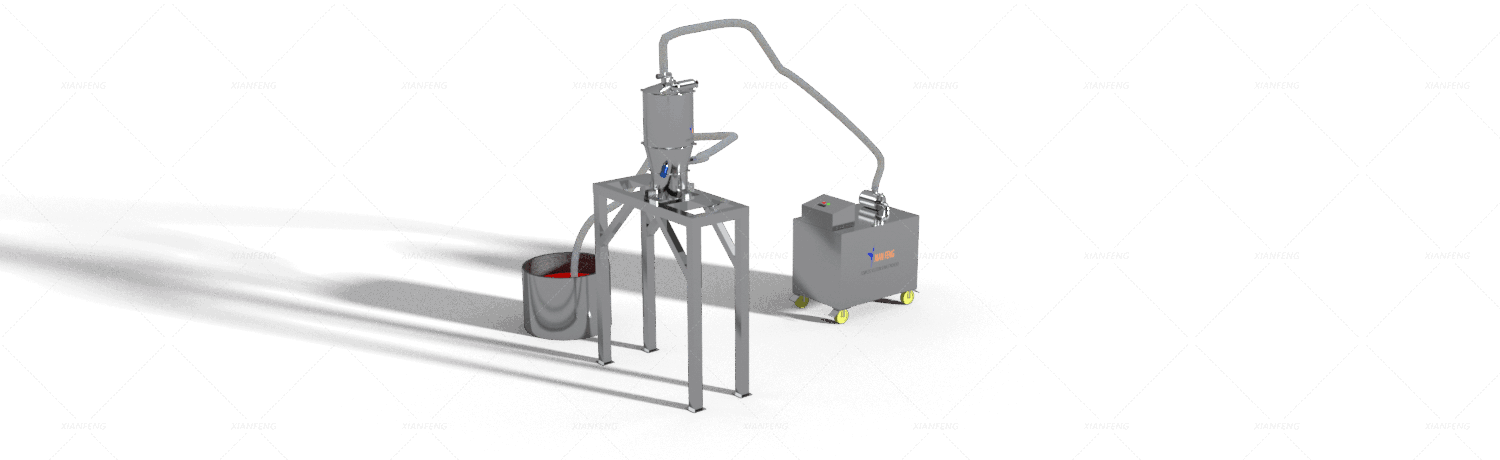

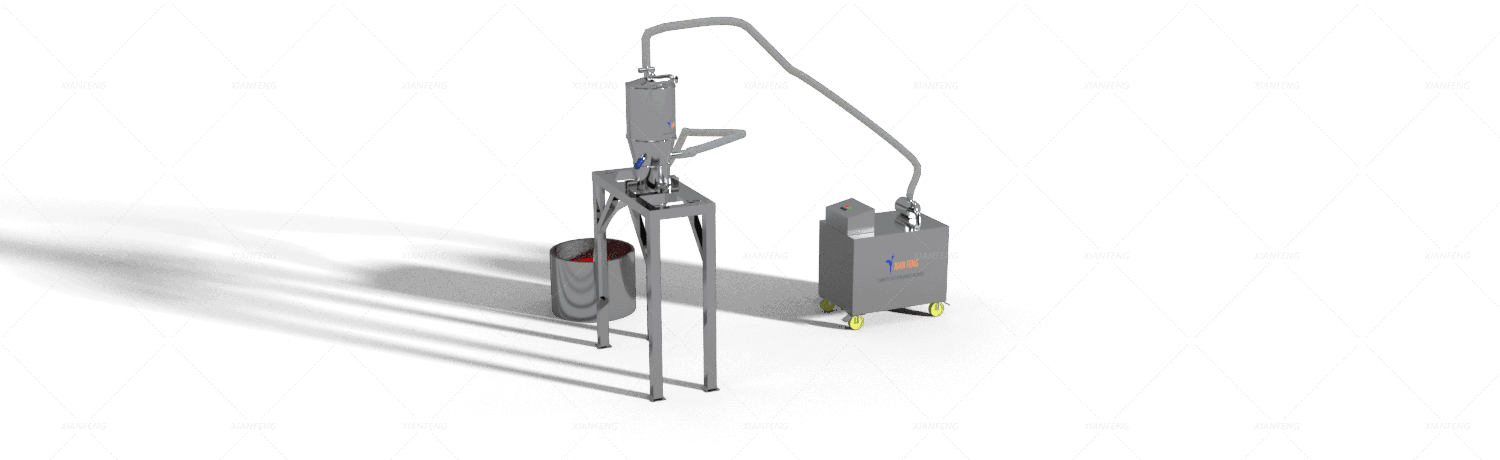

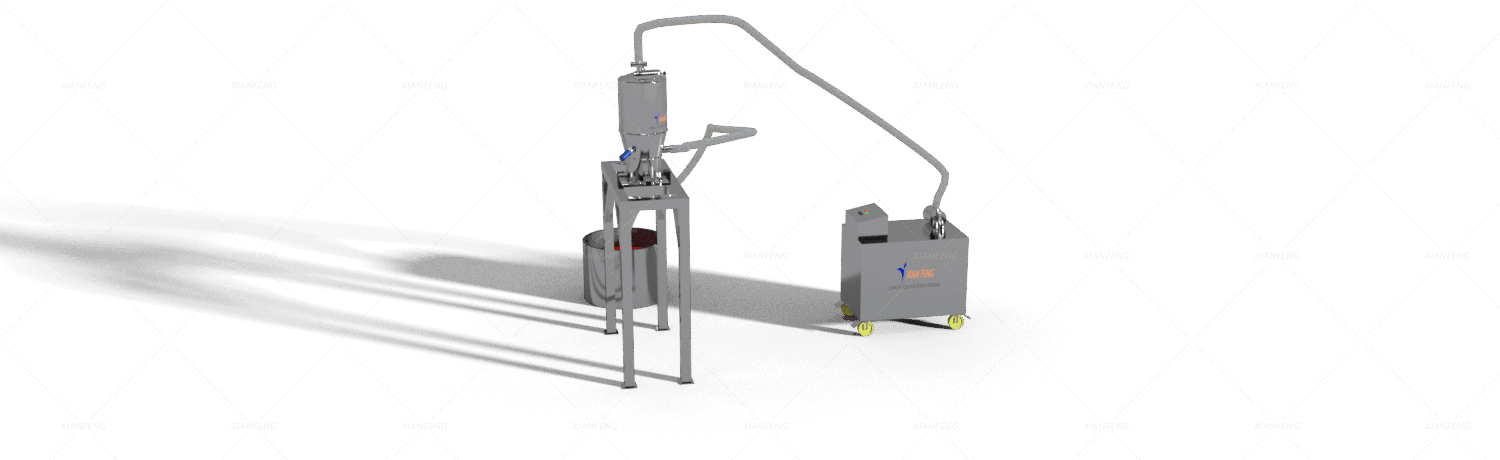

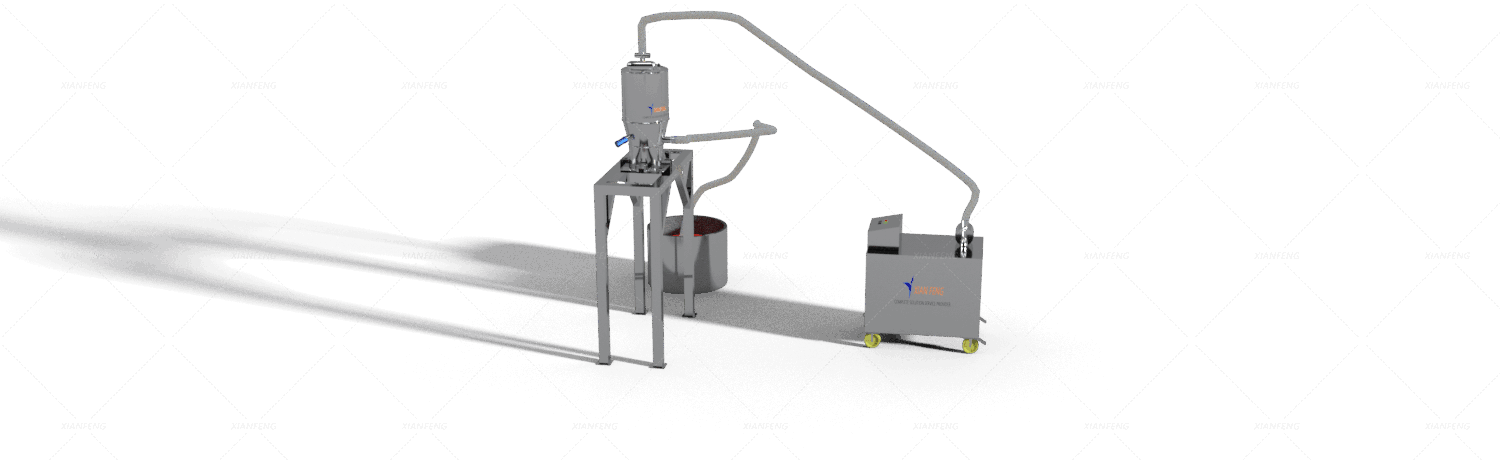

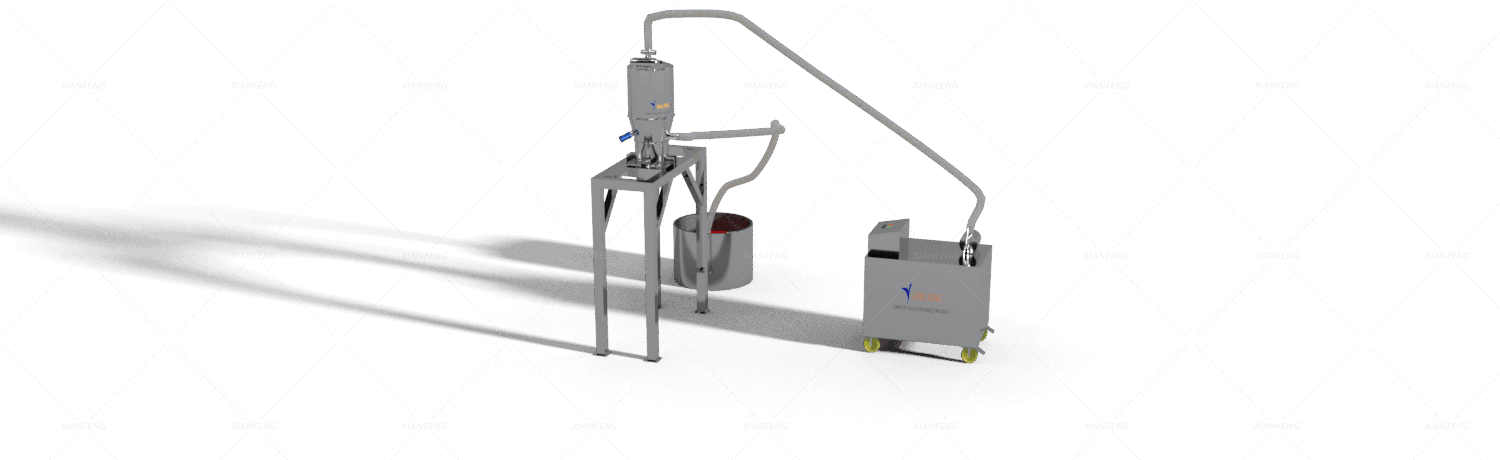

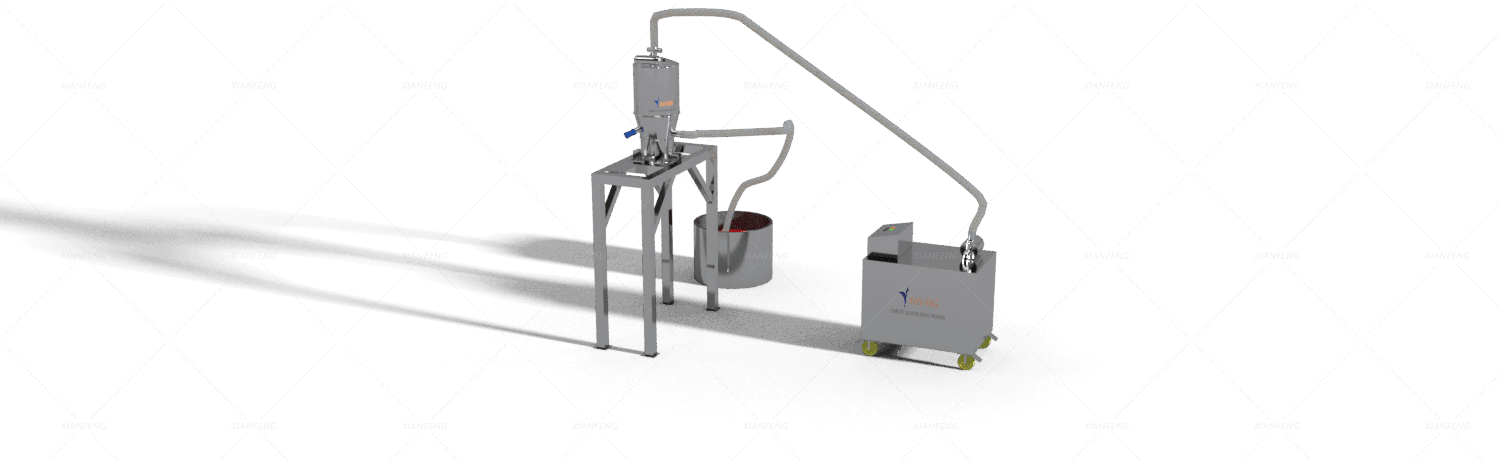

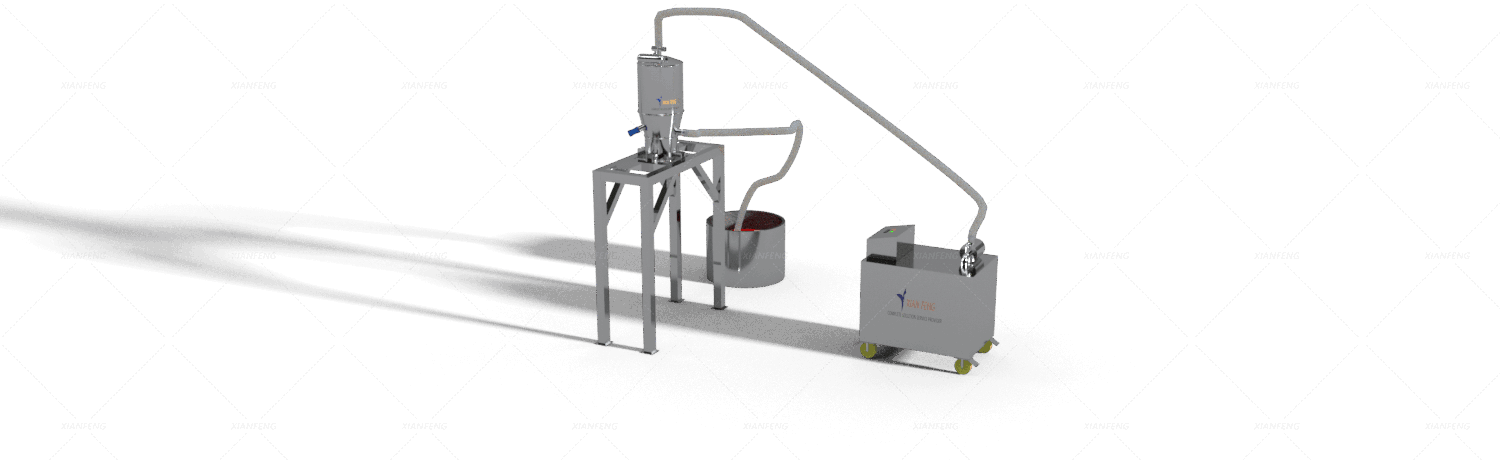

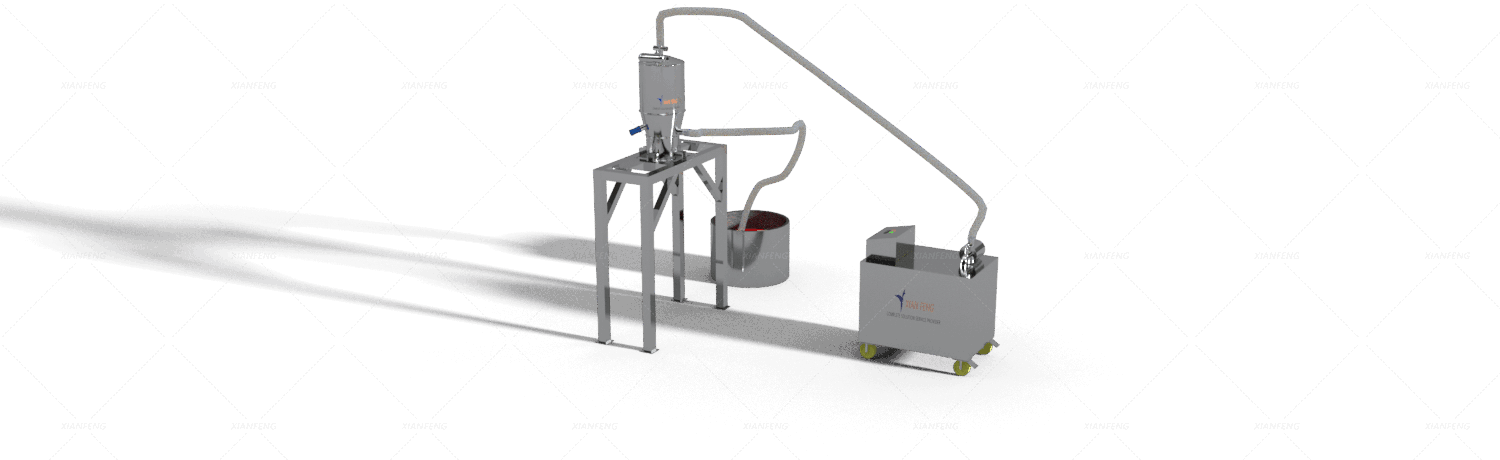

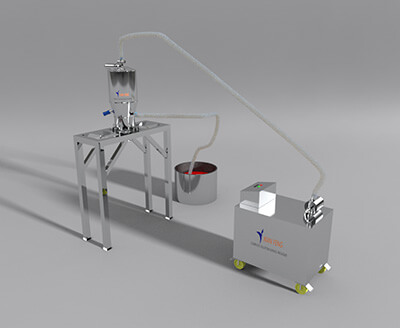

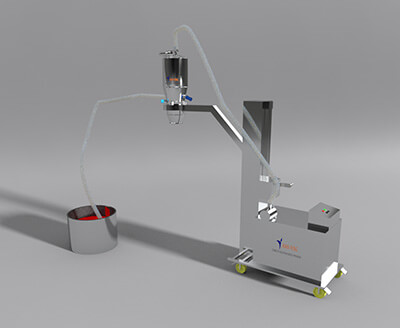

Different from traditional screw conveyors,the working principle of a negative pressure vacuum feeder is to use a vacuum pump as the power source, create negative pressure by extracting air from the system, create air pressure between the equipment suction port and the outside, and drive air to carry materials (such as powder and particles) into the pipeline, while forming a high-speed airflow sufficient to wrap the materials and transport them to the separation tank; The separation tank experiences a sudden drop in airflow velocity due to the expansion of its internal space, causing the material to settle to the bottom of the tank under the influence of gravity. The air is then filtered through a top filter (which intercepts residual material) and discharged by a vacuum pump (the filter element periodically cleans the powder on the filter element through a blowback system to ensure continuous operation of the air flow); When the material in the tank reaches the set amount, the vacuum pump pauses and the bottom discharge valve opens to unload the material to the target equipment. Then, the discharge valve closes and the vacuum pump restarts, entering the next cycle of "negative pressure suction material separation discharge", achieving the full process of closed material transportation.

Negative pressure power source vacuum pump type: Vortex vacuum pump is suitable for small output fine conveying, Roots vacuum pump is used for large output long-distance continuous conveying

There are two types of power sources: electric and pneumatic

made of SS304/316L stainless steel material, with mirror polished inner walls to effectively prevent material adhesion. Some models are designed with S-shaped curved edges, supporting quick disassembly and cleaning without tools.

Suction device:

Stainless steel adjustable suction gun: adaptable to different container heights, supporting various forms of materials such as particles and powders;

Conveyor pipes: Flexible materials such as silicone hoses and PU hoses have a wide range of application scenarios, including bendability, easy installation, and vibration buffering. Stainless steel pipes are mostly made of 304 or 316L stainless steel, with core advantages of "high strength, high stability, corrosion resistance, and easy cleaning", making them the mainstream choice for industrial grade fixed production lines.

Filter configuration: Provides multi-level filtering solutions:

Basic type: Polyester film filter, with a filtration accuracy of 99.9%;

High end type: Titanium sintered filter, wear-resistant and corrosion-resistant, with a service life of more than 5 times that of ordinary filter materials, and can effectively eliminate material static electricity.

Backblowing cleaning system: By using compressed air pulses to blow back, it automatically removes dust adhering to the surface of the filter material, ensuring continuous and stable filtration efficiency.

Level monitoring: Capacitive or ultrasonic level sensors detect the height of materials in the hopper in real time, achieving automatic start stop (control accuracy ± 5mm).

Operation interface:

Basic model: Mechanical button control, suitable for simple working conditions;

Intelligent model: PLC touch screen+remote monitoring module, supporting parameter preset, fault diagnosis, and production data traceability.

Pneumatic discharge door: Butterfly valves or star shaped discharge valves are used to meet different production requirements.

Shock absorption device: rubber isolation pad+spring hanger combination reduces noise. Quick opening device: easier disassembly and maintenance.

Flour vacuum conveying| vacuum conveying system

Chemical powder conveying | powder transfer system

Cassava powder conveying | material conveying system

Food powder conveying | air powered vacuum conveyor

| Model | Motor power(kw) | Capacity(kg/h) | |

| ZKS-1 | 1.5 | 400 | |

| ZKS-2 | 2.2 | 600 | |

| ZKS-3 | 3 | 1200 | |

| ZKS-4 | 5.5 | 2500 | |

| ZKS-6 | 5.5 | 3200 | |

| ZKS-7 | 7.5 | 6000 | |

| ZKS-10-6 | 7.5 | 6000(length 10m) | |

| ZKS-20-5 | 11 | 5000(length 10m) | |

Transportable materials include various powders (such as flour, milk powder, cement powder), granules (such as plastic pellets, quartz sand), and small pieces of materials (such as nuts, etc.); Unsuitable materials: Highly viscous materials such as wet dough and asphalt paste, which are prone to clogging pipes and filters; Ultra coarse/overweight block materials such as sand and gravel; Materials that are prone to sublimation/gasification, such as dry ice;

Follow the steps below to troubleshoot: ① Check the vacuum pump for oil shortage (oil type vacuum pump) and normal motor speed. If the vacuum pump malfunctions, it needs to be repaired or replaced; ② Check the sealing: whether the suction port is in contact with the material pile (whether there are any air leakage gaps), whether the pipeline interface/discharge valve is not tightly sealed, and replace the aging sealing ring; ③ Check the filter: whether it is blocked by materials (especially fine powder), remove it and clean it with compressed air or replace the filter material; ④ Check the material: whether it has clumped due to moisture (clumped material blocks the suction port), and the material needs to be broken or dried first.

Explosion proof vacuum feeding machine must be selected, with core configuration: ① Explosion proof vacuum pump (motor with explosion-proof rating, such as Ex d IIB T4); ② Anti static pipeline/separation tank (transported by metal pipeline and made of stainless steel with grounding treatment to prevent static electricity accumulation); ③ Explosion proof sensors and control boxes (such as level sensors, button switches, to avoid electric sparks); ④ Inert gas protection (optional, when transporting highly flammable materials such as aluminum powder, fill the system with nitrogen to reduce oxygen concentration).

Vacuum feeding machines are mainly classified into two types based on their power sources: electric drive and pneumatic drive. Electric drive uses devices such as vortex fans and Roots fans to generate vacuum negative pressure for conveying materials, with low energy consumption and low noise, making it the preferred choice for most ordinary working conditions. Pneumatic safety explosion-proof is more suitable for hazardous environments such as chemical engineering, but it has high noise and energy consumption.

According to the working mode, it can be divided into intermittent and continuous types. Intermittent type adopts intermittent work of first sucking and then discharging, and then reciprocating cycle. It has a simple structure and low cost, and is suitable for most conveying conditions. Continuous type refers to the simultaneous suction and discharge of materials, with uninterrupted material flow, which can meet the high requirements for continuous feeding in production lines. However, the cost is also higher, and double compartments can be customized according to demand to meet larger production needs.

Yes, the vacuum feeder can achieve simultaneous feeding of materials by one device.

One to two:

This is the most common basic configuration, which feeds two hoppers simultaneously through a vacuum pump or fan. For example, in the dust-free feeding system of the pharmaceutical industry, a vacuum feeder can alternately transport materials to two reaction vessels, achieving closed operation and reducing dust pollution. In plastic processing, the one to two system can simultaneously process crushed materials and PP pellets, with horizontal conveying of 12 meters and vertical conveying of 10 meters, meeting the production capacity demand of 600kg/h.

From one to three to one to five:

Large and medium-sized systems often adopt this type of configuration. For example, a certain engineering plastic production line uses Roots blower type air conveying system to feed three hoppers through the one driven three mode, and realizes high-precision proportioning in combination with the weight-loss feeder. In the chemical industry, the one to four system can simultaneously transport four types of materials including calcium carbonate powder and PVC, with a conveying capacity covering 250-600kg/h

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.