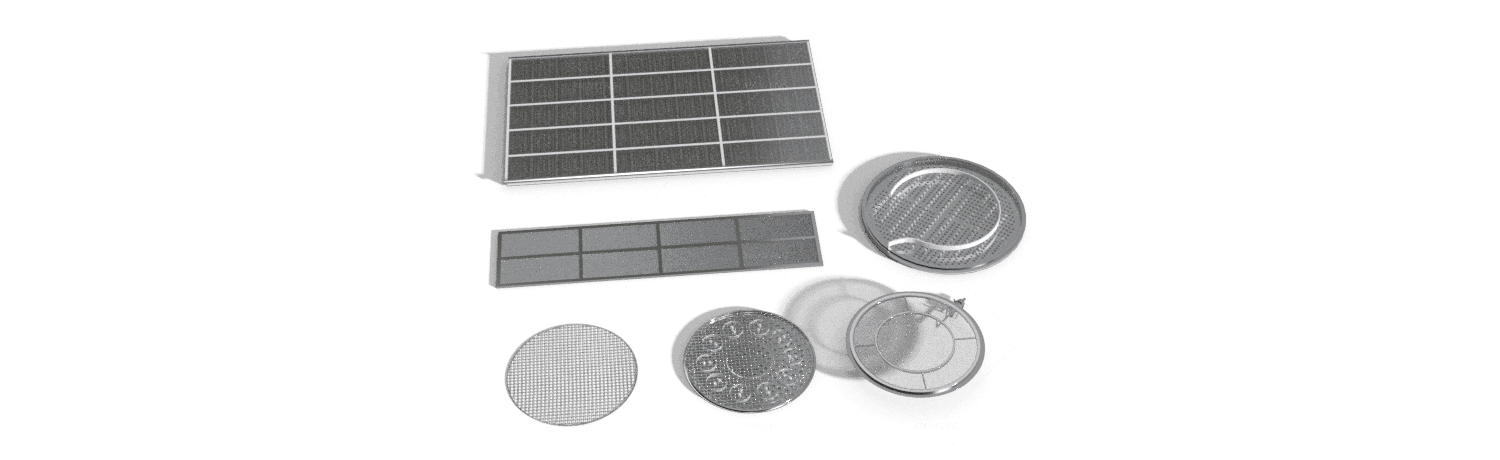

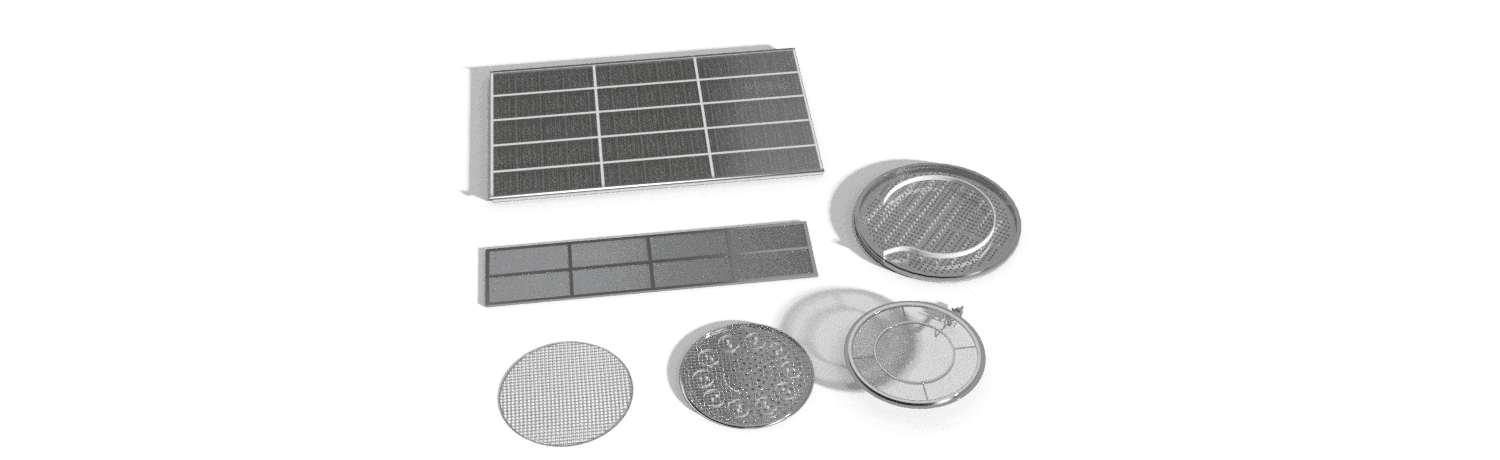

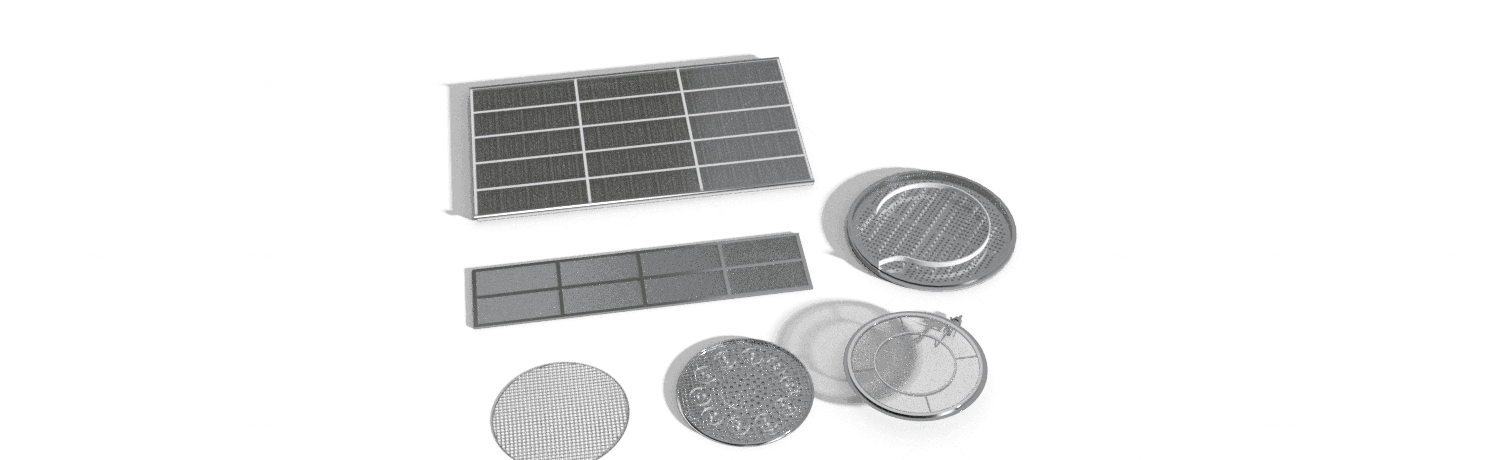

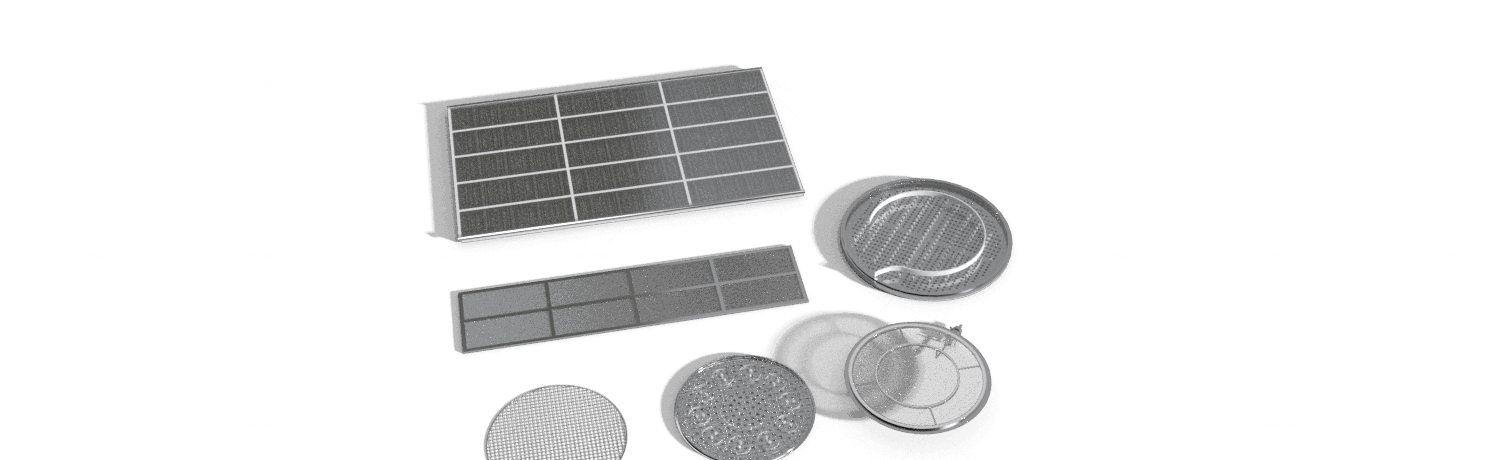

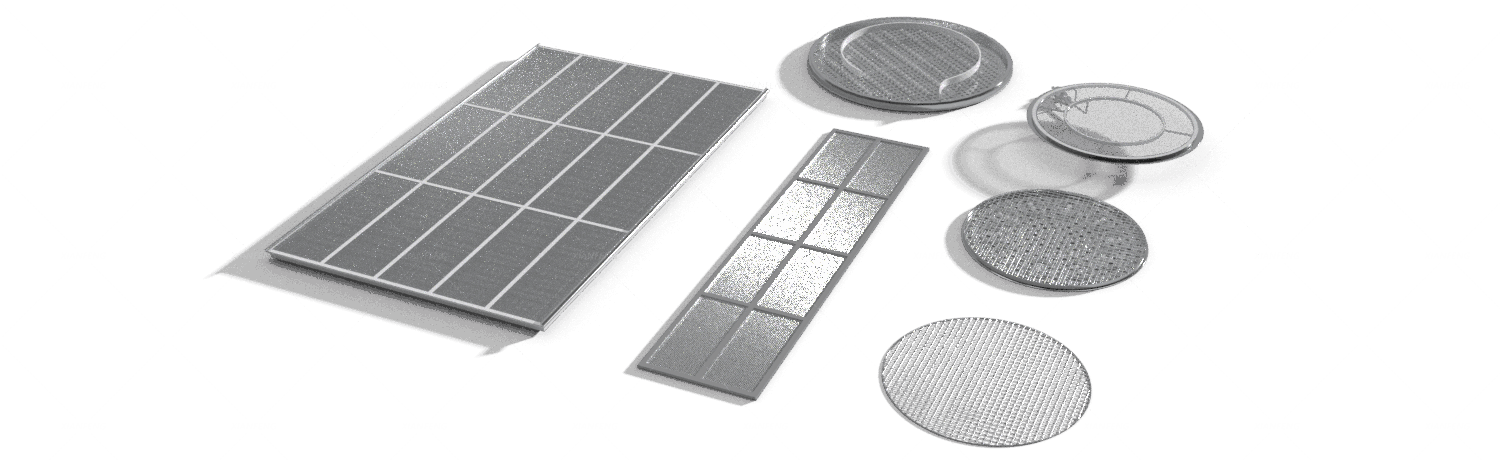

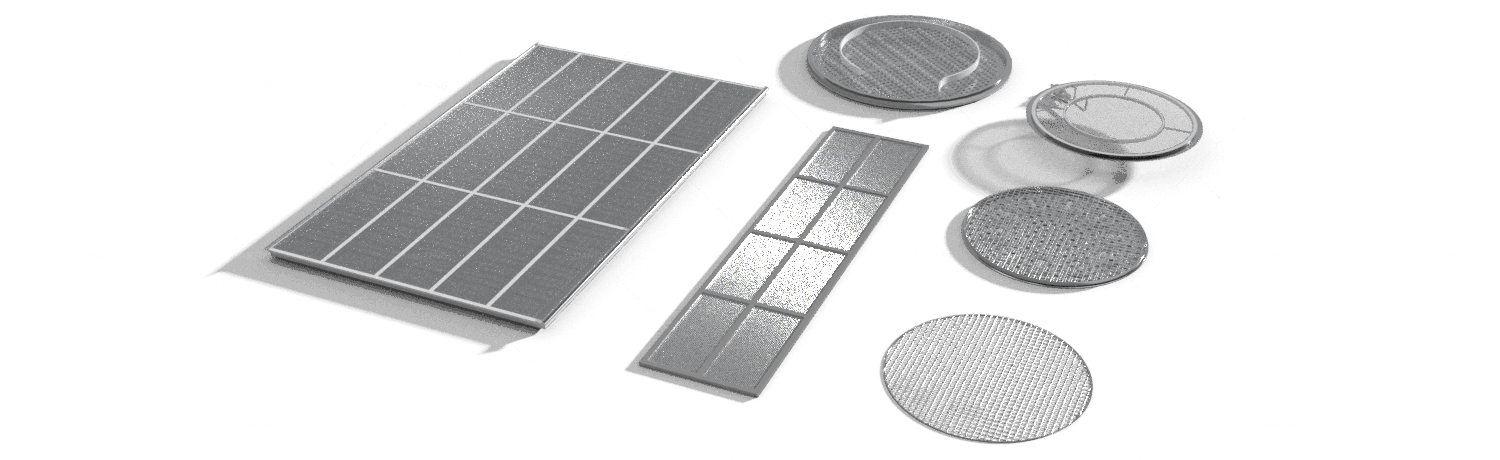

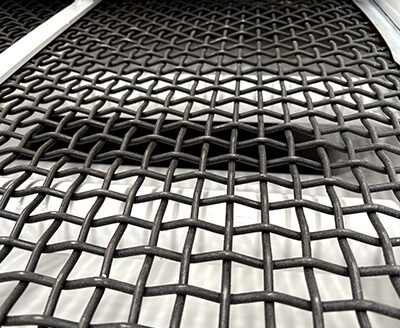

The vibrating screen mesh is the core component of the industrial vibrating screen used for grading materials. Common types include stainless steel metal woven mesh, punched plate mesh, bar mesh, polyurethane mesh, etc. The mesh holes include square holes, circular holes, rectangular holes, etc. The principle is to distinguish the size of materials by the mesh size of the screen mesh. Large particle materials are isolated above the screen mesh, and small particle materials pass through the screen mesh to complete material screening. The range of mesh aperture size is 0.03mm to 100mm

If you want to learn more, you can directly contact us to communicate details..

Flour, powdered sugar, milk powder, fruit juice, nuts, tea, dried flowers, pet food, etc.

Pills, pills, powders, capsules, intermediates, excipients, etc

Coatings, hydrochloric acid, resin particles, fluorescent powder, nitric acid, sodium hydroxide, sodium carbonate, etc

Coal, quartz sand, lime powder, cement powder, dry sand, soil, glass, talcum powder, etc

Iron powder, copper powder, aluminum powder, tungsten powder, titanium powder, nickel powder, zinc powder, etc

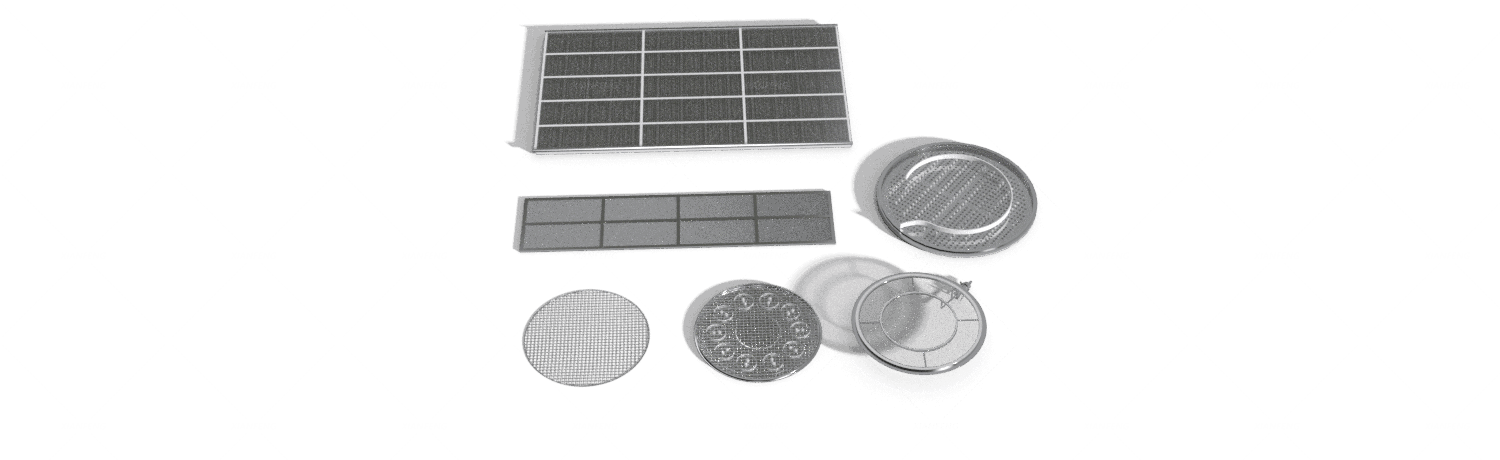

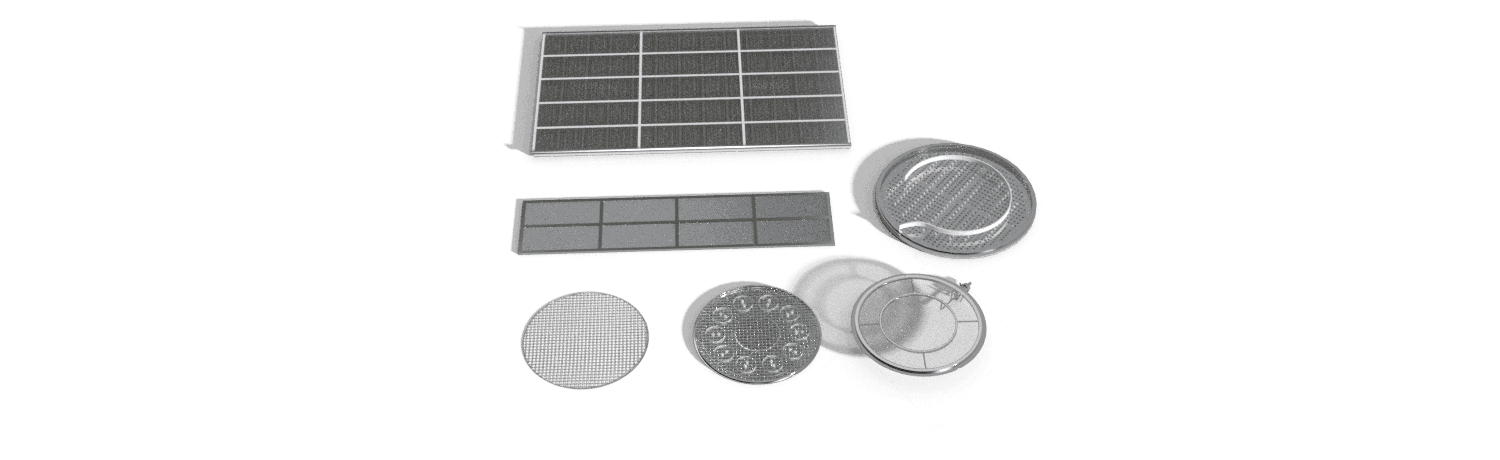

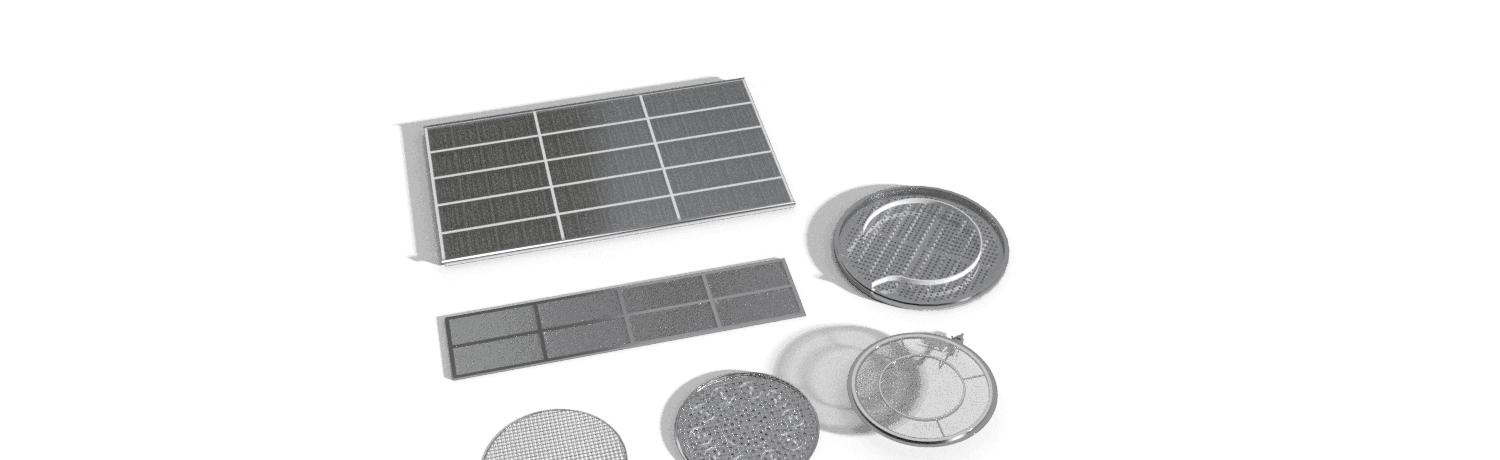

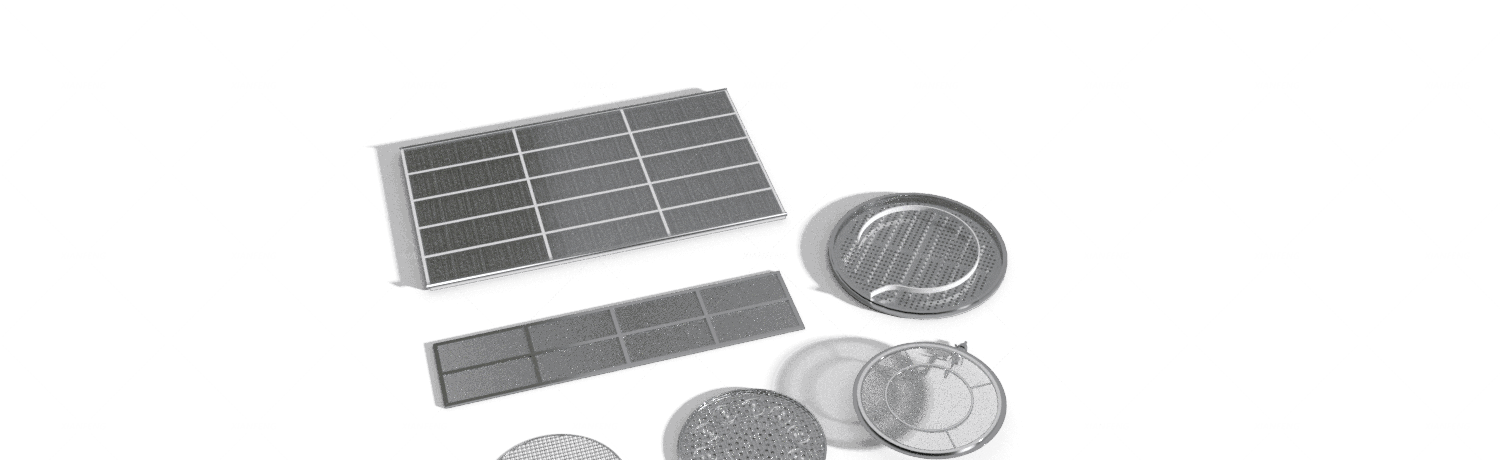

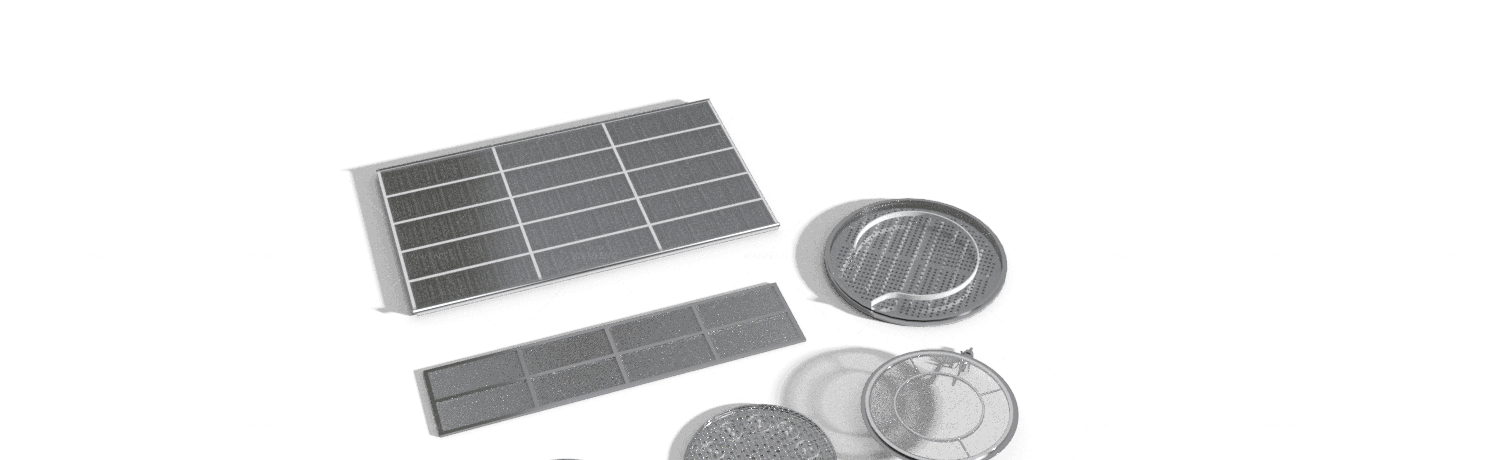

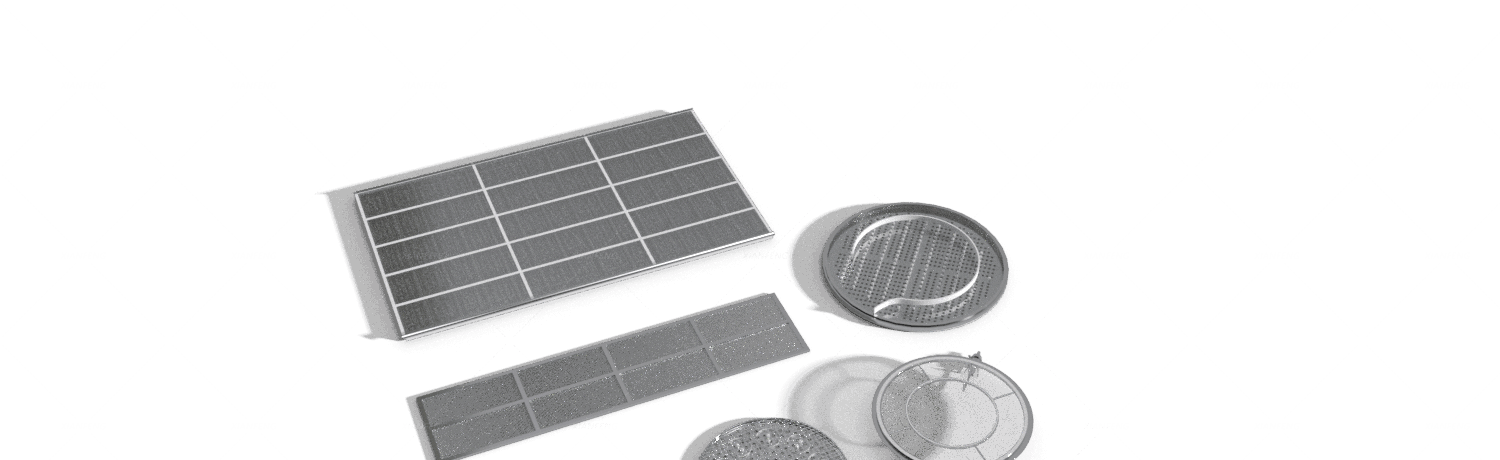

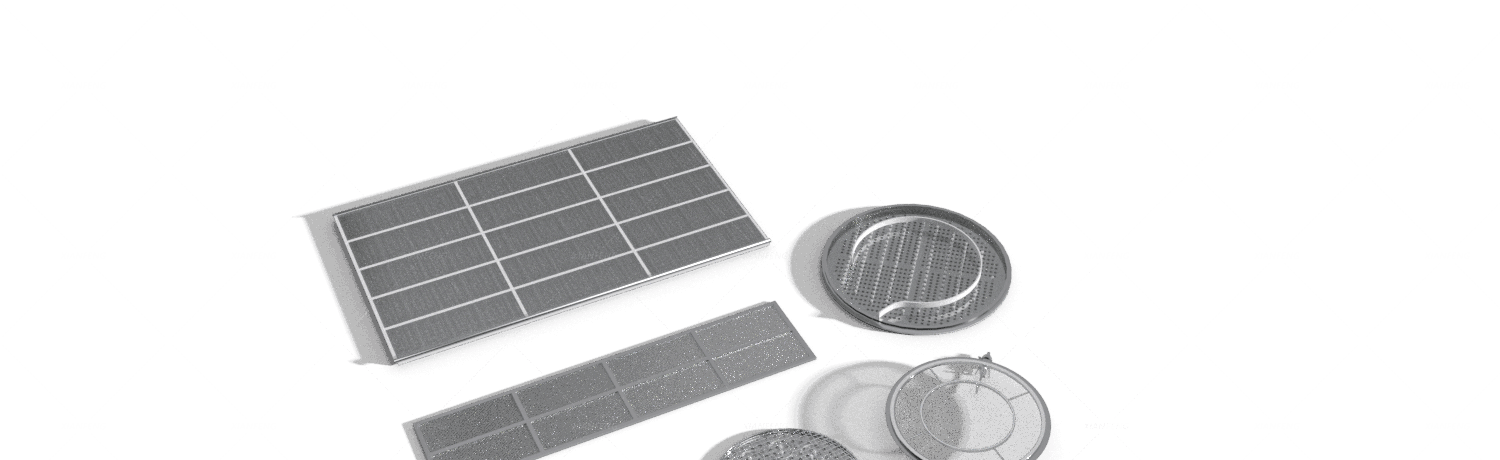

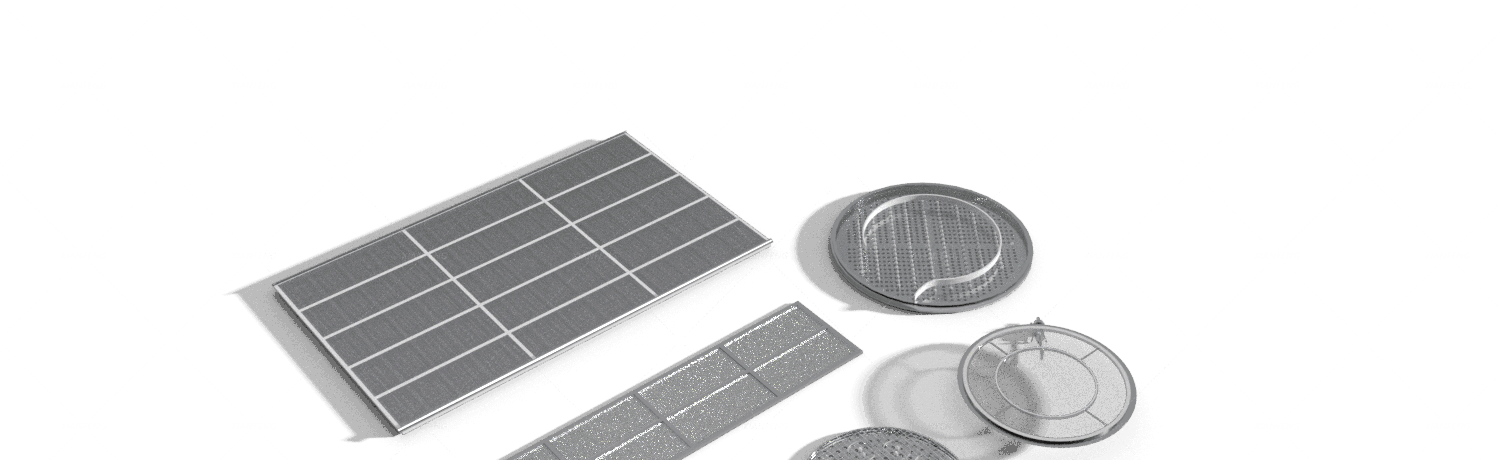

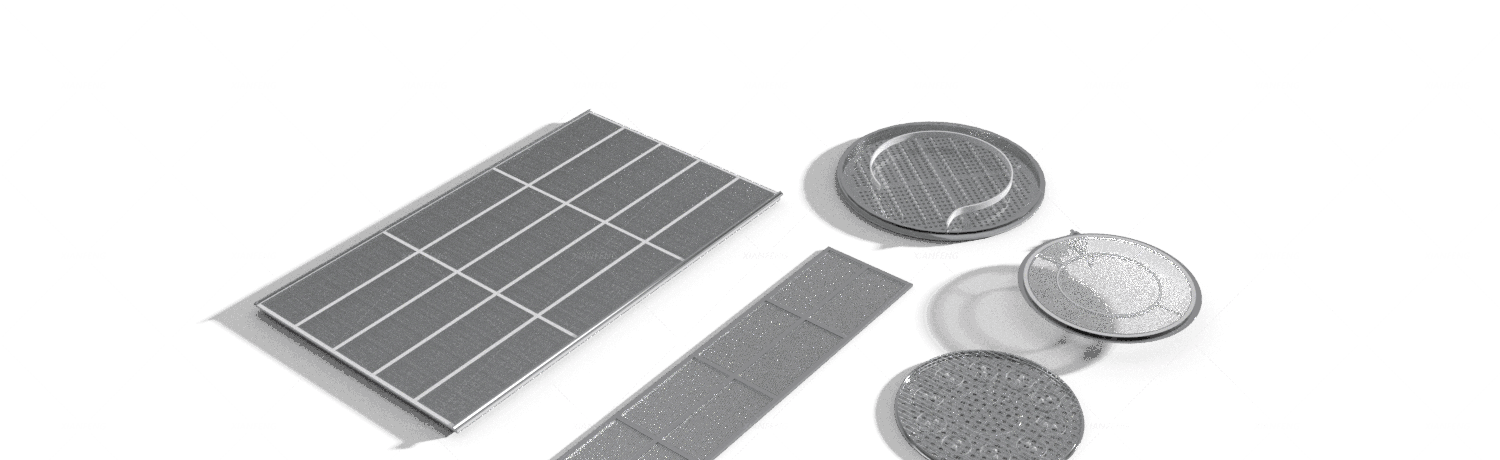

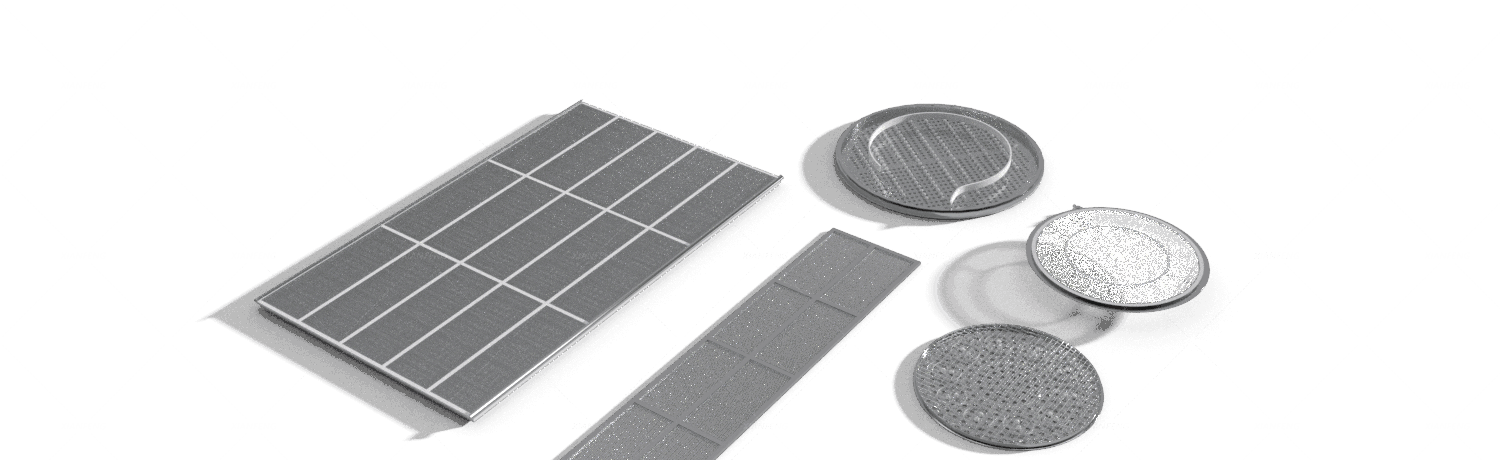

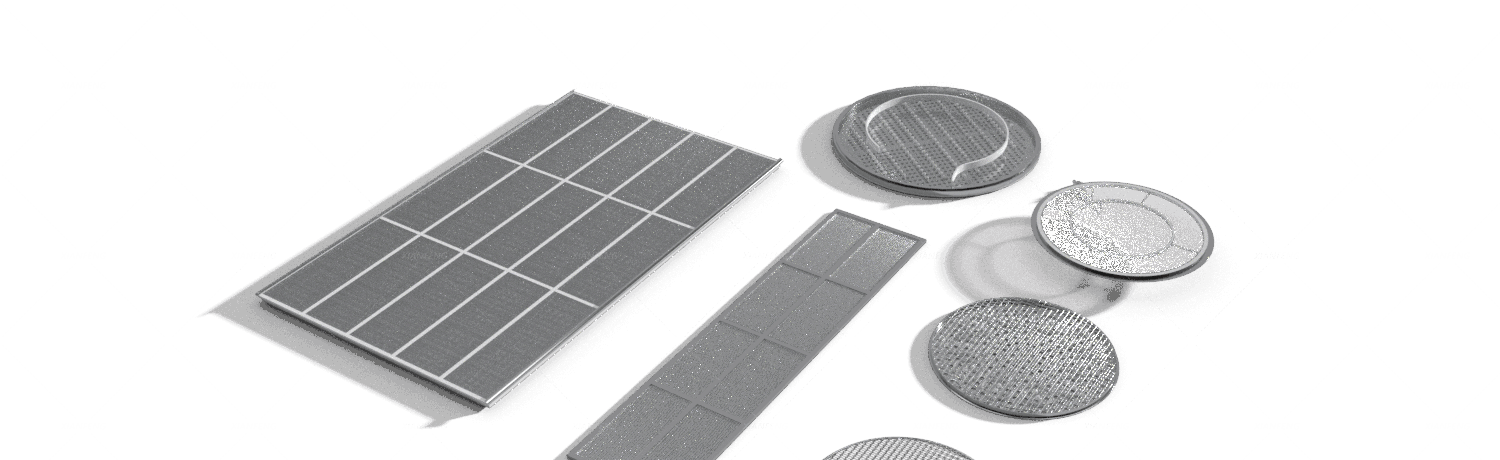

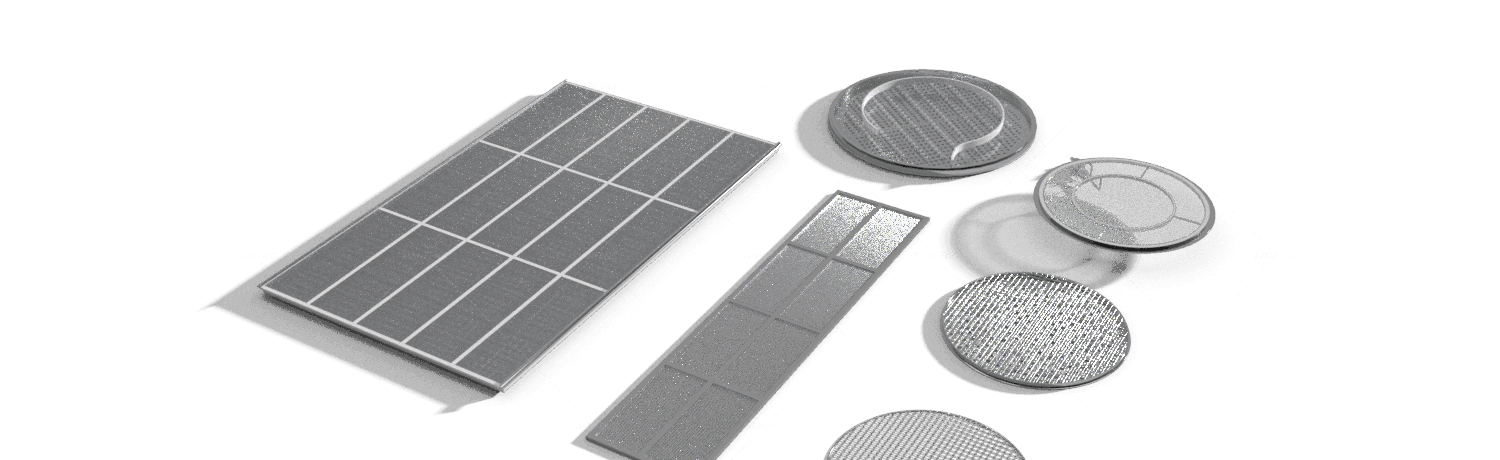

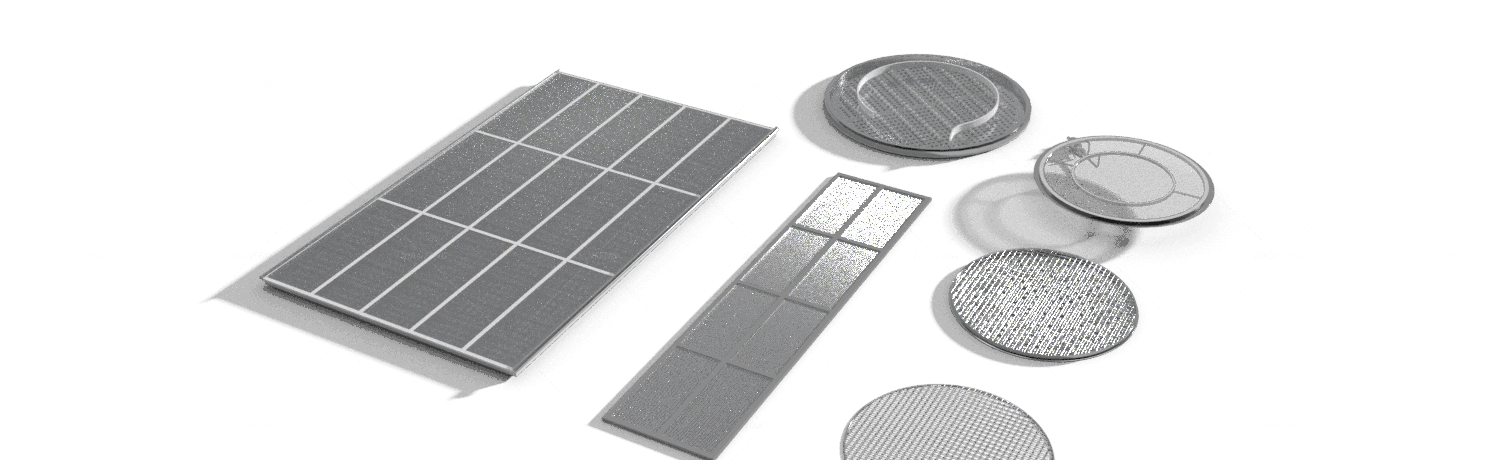

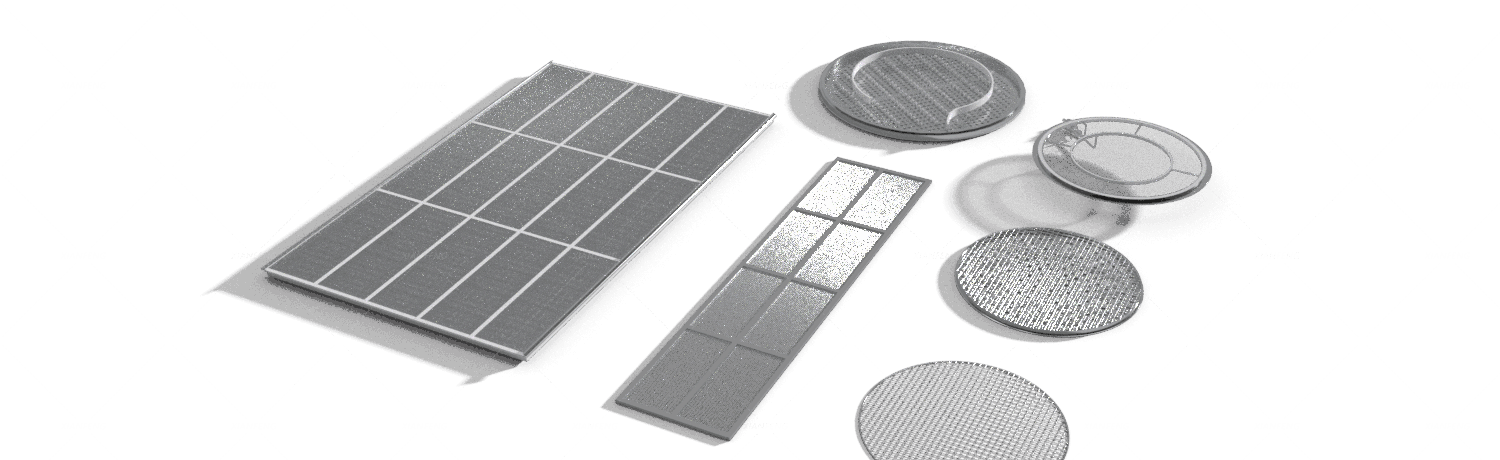

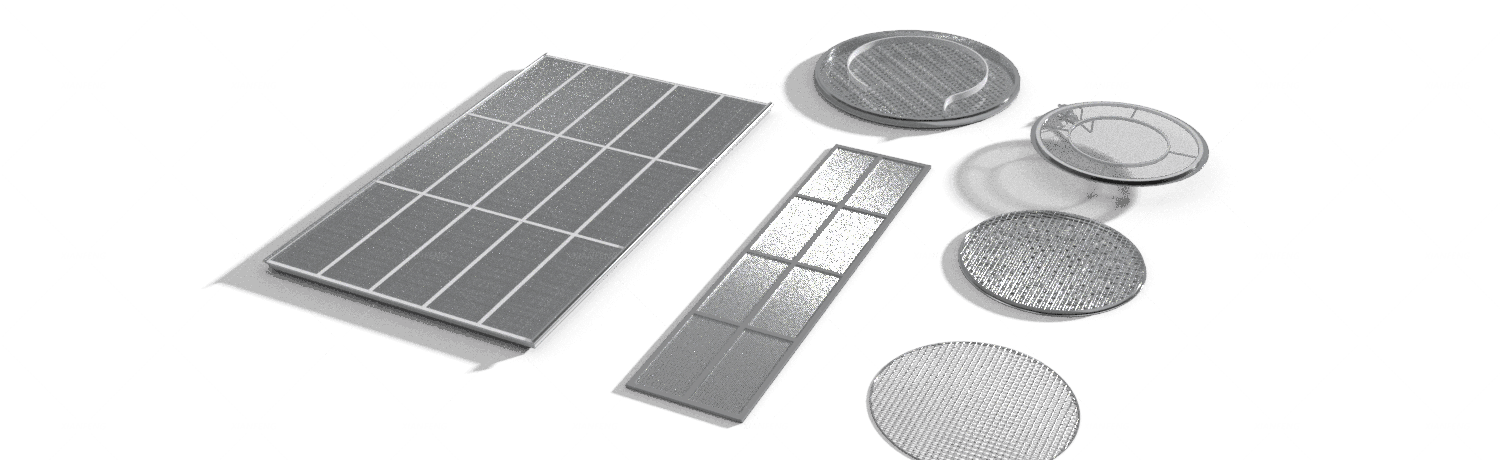

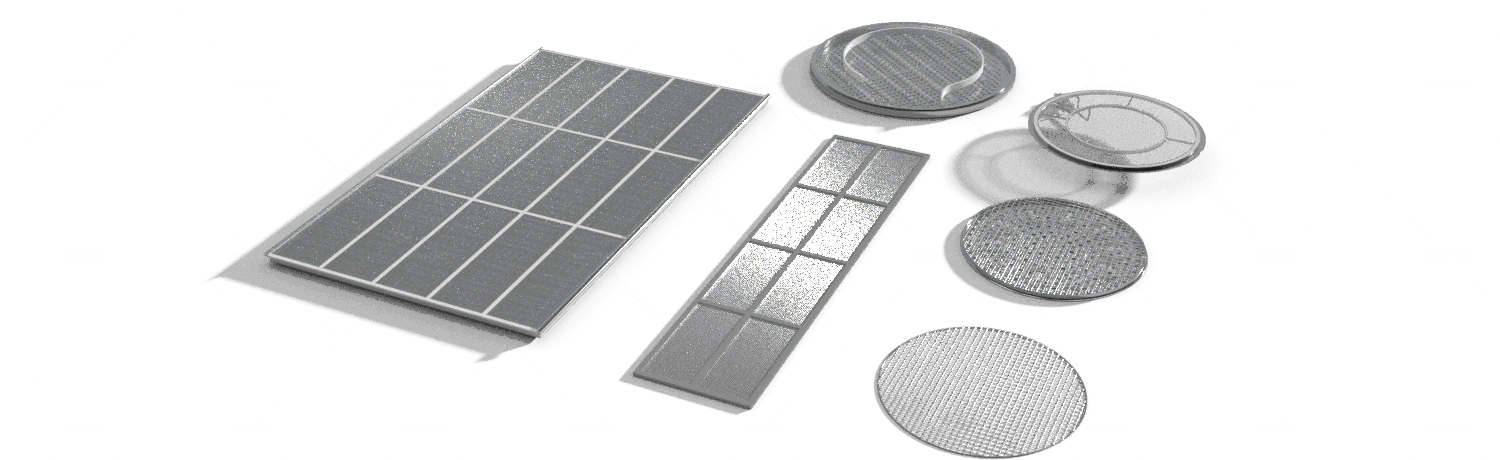

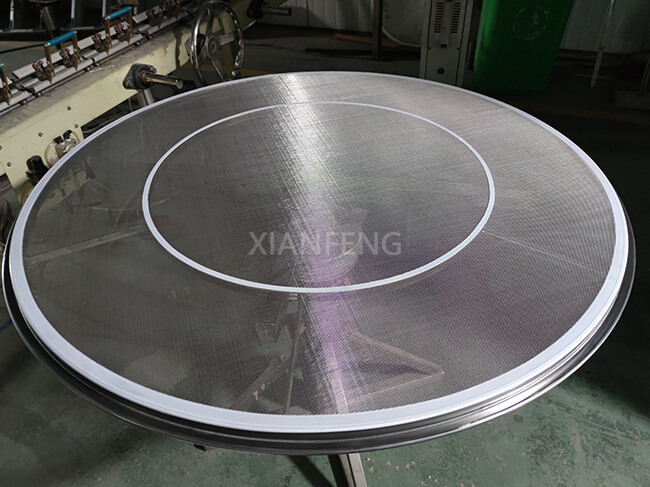

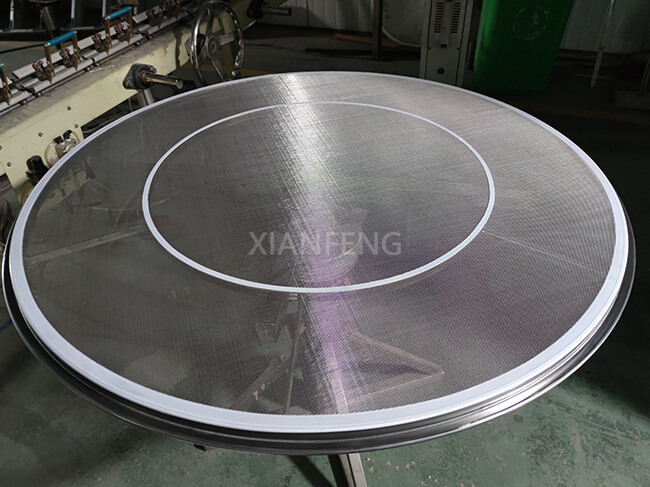

Circular sieve mesh

Screen mesh

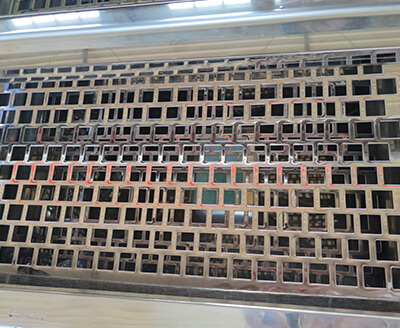

Grid support and fixation

Discharge outlet

The circular screen mesh with a mesh size of 2-200 mesh can be assembled according to customer requirements and is commonly used in equipment such as circular vibrating screens, swing screens, straight row vibrating screens, and high-frequency screens. You can also customize punched plate screen mesh.

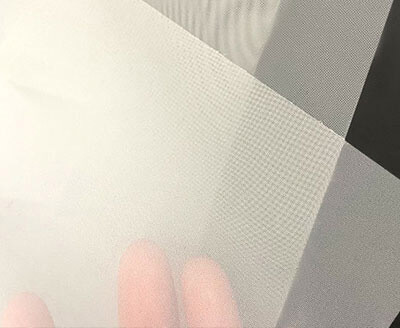

Circular mesh screen with a mesh range of 200-500, selected according to customer requirements, commonly used for screening and processing ultrafine powder materials.

The compatible equipment includes ultrasonic vibrating screen, ultrasonic swinging screen, airtight screen, ultrasonic inspection screen, etc.

Square mesh or punched mesh, with a pore size range of 0.074mm-10cm, can be customized and selected according to customer requirements. It is commonly used in equipment such as linear vibrating screens and probability screens.

Square swing screen special sieve, available in the 0.074-2mm range, is a specialized sieve for square swing screen equipment.

Vibration screen mesh is commonly used for metal woven stainless steel mesh, metal punched plate, nylon mesh, polyurethane mesh, etc. We can customize different types of screens according to the actual needs of customers, such as square holes, round holes, rectangular holes, bar grid style, etc. Process sieve mesh in the range of 2-500 mesh.

| Mesh NO. |

(mm) Aperture |

(mm) Wire dia |

(%) Screenin g area |

Mesh/inch | Mesh NO. |

(mm) Aperture |

(mm) Wire dia |

Screenin g area(%) |

Meshinch |

| 3.5# | 5.6 | 1.6 | 60 | 3.53 | 50# | 0.3 | 0.14 | 46 | 57.73 |

| 4# | 4.75 | 1 | 68 | 4.42 | 54# | 0.28 | 0.14 | 44 | 60.48 |

| 5# | 4 | 1 | 64 | 5.08 | 57# | 0.265 | 0.125 | 43 | 65.13 |

| 5.5# | 3.55 | 0.8 | 67 | 5.84 | 60# | 0.25 | 0.125 | 44 | 67.73 |

| 6# | 3.35 | 0.8 | 65 | 6.12 | 65# | 0.236 | 0.125 | 43 | 70.36 |

| 6.5# | 3.15 | 0.8 | 64 | 6.43 | 68# | 0.224 | 0.125 | 41 | 72.78 |

| 7# | 2.8 | 0.71 | 51 | 7.24 | 70# | 0.212 | 0.125 | 40 | 75.37 |

| 7.5# | 2.5 | 0.63 | 64 | 8.12 | 75# | 0.2 | 0.125 | 38 | 78.15 |

| 8.# | 2.36 | 0.56 | 65 | 8.70 | 78# | 0.19 | 0.125 | 36 | 80.63 |

| 9# | 2.24 | 0.56 | 64 | 9.07 | 80# | 0.18 | 0.125 | 35 | 83.28 |

| 10# | 2 | 0.63 | 58 | 9.66 | 90# | 0.16 | 0.1 | 35 | 97.69 |

| 10# | 2 | 0.5 | 64 | 10.16 | 100# | 0.15 | 0.1 | 36 | 101.60 |

| 11# | 1.8 | 0.5 | 62 | 11.04 | 110# | 0.14 | 0.09 | 37 | 110.43 |

| 12# | 1.7 | 0.45 | 63 | 11.81 | 120# | 0.125 | 0.09 | 34 | 118.14 |

| 12.5# | 1.6 | 0.45 | 61 | 12.39 | 130# | 0.112 | 0.063 | 41 | 145.14 |

| 13# | 1.5 | 0.4 | 62 | 13.37 | 140# | 0.106 | 0.063 | 39 | 150.30 |

| 14# | 1.4 | 0.4 | 60 | 14.11 | 150# | 0.1 | 0.063 | 38 | 155.83 |

| 15# | 1.25 | 0.4 | 57 | 15.39 | 160# | 0.095 | 0.063 | 36 | 160.76 |

| 16# | 1.18 | 0.4 | 56 | 16.08 | 170# | 0.09 | 0.063 | 35 | 166.01 |

| 16.5# | 1.12 | 0.355 | 58 | 17.22 | 180# | 0.085 | 0.056 | 36 | 180.14 |

| 17# | 1.06 | 0.355 | 56 | 17.95 | 190# | 0.08 | 0.056 | 35 | 186.76 |

| 18# | 1 | 0.355 | 54 | 18.75 | 200# | 0.075 | 0.05 | 34 | 203.20 |

| 18.5# | 0.95 | 0.355 | 52 | 19.46 | 210# | 0.071 | 0.056 | 31 | 200.00 |

| 19# | 0.9 | 0.355 | 51 | 20.24 | 220# | 0.067 | 0.05 | 34 | 217.09 |

| 20# | 0.85 | 0.315 | 53 | 21.80 | 230# | 0.063 | 0.045 | 34 | 235.19 |

| 22# | 0.8 | 0.315 | 51 | 22.78 | 240# | 0.06 | 0.04 | 33 | 254.00 |

| 24# | 0.75 | 0.28 | 53 | 24.66 | 260# | 0.056 | 0.04 | 33 | 264.58 |

| 25# | 0.71 | 0.28 | 51 | 25.66 | 270# | 0.053 | 0.04 | 33 | 273.12 |

| 27# | 0.67 | 0.25 | 51 | 27.61 | 290# | 0.05 | 0.036 | 34 | 295.35 |

| 29# | 0.63 | 0.25 | 51 | 28.86 | 300# | 0.048 | 0.036 | 35 | 302.38 |

| 30# | 0.6 | 0.25 | 50 | 29.88 | 325# | 0.045 | 0.036 | 31 | 313.58 |

| 32# | 0.56 | 0.224 | 51 | 32.40 | 340# | 0.042 | 0.036 | 31 | 325.64 |

| 35# | 0.5 | 0.224 | 48 | 35.08 | 360# | 0.04 | 0.03 | 31 | 362.86 |

| 38# | 0.475 | 0.18 | 53 | 38.78 | 400# | 0.038 | 0.025 | 36 | 403.17 |

| 39# | 0.45 | 0.18 | 51 | 40.32 | 420# | 0.036 | 0.028 | 31 | 396.88 |

| 40# | 0.425 | 0.16 | 53 | 43.42 | 450# | 0.032 | 0.025 | 31 | 445.61 |

| 42# | 0.4 | 0.16 | 51 | 45.36 | 500# | 0.028 | 0.022 | 31 | 508.00 |

| 44# | 0.375 | 0.16 | 49 | 47.48 | 520# | 0.025 | 0.025 | 25 | 508.00 |

| 45# | 0.355 | 0.14 | 51 | 51.31 | 600# | 0.02 | 0.02 | 24 | 635.00 |

| 47# | 0.335 | 0.14 | 50 | 53.47 | 800# | 0.015 | 0.018 | 23 | 769.70 |

| 48# | 0.315 | 0.14 | 48 | 55.82 | 1000# | 0.01 | 0.015 | 20 | 1016.00 |

Answer: It needs to be judged based on two core factors:

Material characteristics: Choose polyurethane mesh for wet/viscous materials (such as coal slurry and clay); For corrosive materials (such as acidic and alkaline chemical raw materials), choose 316L stainless steel mesh or polypropylene (PP) plastic mesh.

Particle size: fine particles (0.02-2mm) suitable for metal woven mesh; Medium coarse particles (2-50mm) are selected with perforated sieve plates

Industry standard: The food/pharmaceutical industry must comply with FDA/GMP standards, with priority given to 304 stainless steel mesh or food grade PP mesh; The mining industry focuses on wear resistance and can choose polyurethane mesh or manganese steel woven mesh.

It fully complies. Our food/pharmaceutical grade sieves are certified by globally authoritative standards: stainless steel sieve (304/316L): compliant with EU EC certification, smooth surface without burrs, easy to clean, and no hygiene dead corners; PP/polytetrafluoroethylene (PTFE) plastic sieve: certified as food grade, non-toxic and odorless, can directly contact food/drugs. If you need relevant certification reports, we can provide them at any time.

The common reasons for hole blockage and corresponding solutions are as follows:

Material moisture/high viscosity: Replace with polyurethane screen or install ultrasonic device on the vibrating screen.

The sieve aperture is too small: On the premise of meeting the filtration requirements, replace the sieve with a slightly larger aperture (such as changing from 0.5mm to 0.6mm).

Improper installation: To ensure even tension of the screen mesh (loose screen mesh can easily cause material accumulation), we can use our matching installation buckle to enhance the tension effect.

Supports full dimensional customization. You need to provide the following 4 types of information:

2. Screen size: For circular screens, the diameter should be provided, while for square/rectangular screens, the length x width should be provided, and the position and size of the installation holes should be indicated;

3. Hole shape and aperture: Clearly define the hole shape (circular, square, rectangular, or special shape) and aperture/spacing;

4. Material requirements: For example, used for screening 5mm pharmaceutical powder;

5. Application scenarios: such as "mining sand and gravel screening" and "food grade white sugar grading".

Customized delivery time: 7-15 days (depending on the complexity of customization), design drawings will be provided for your confirmation before production.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.