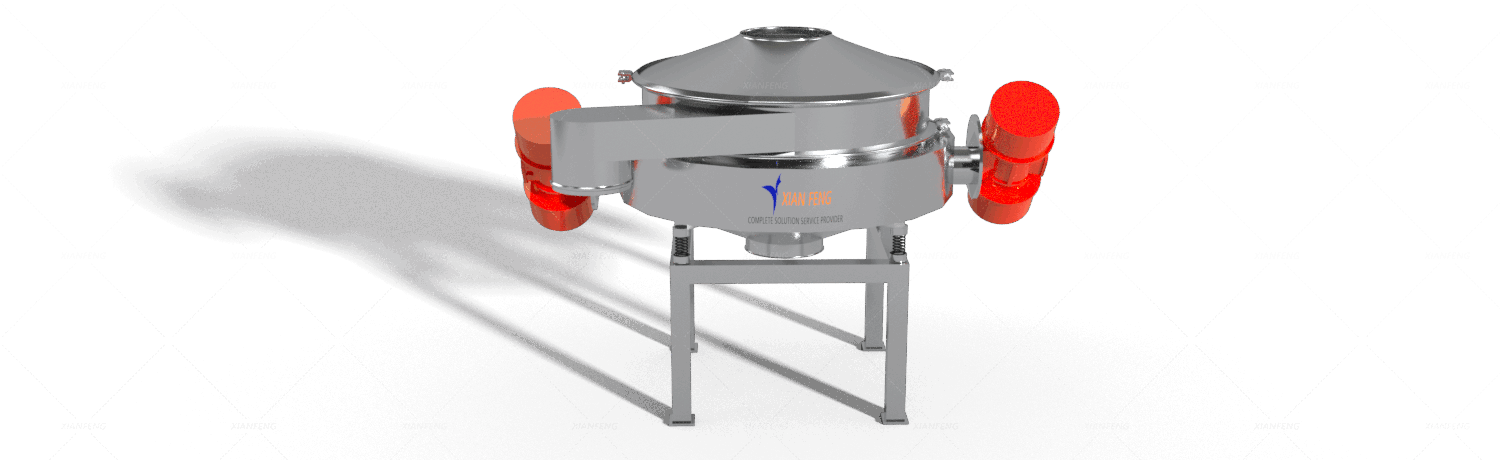

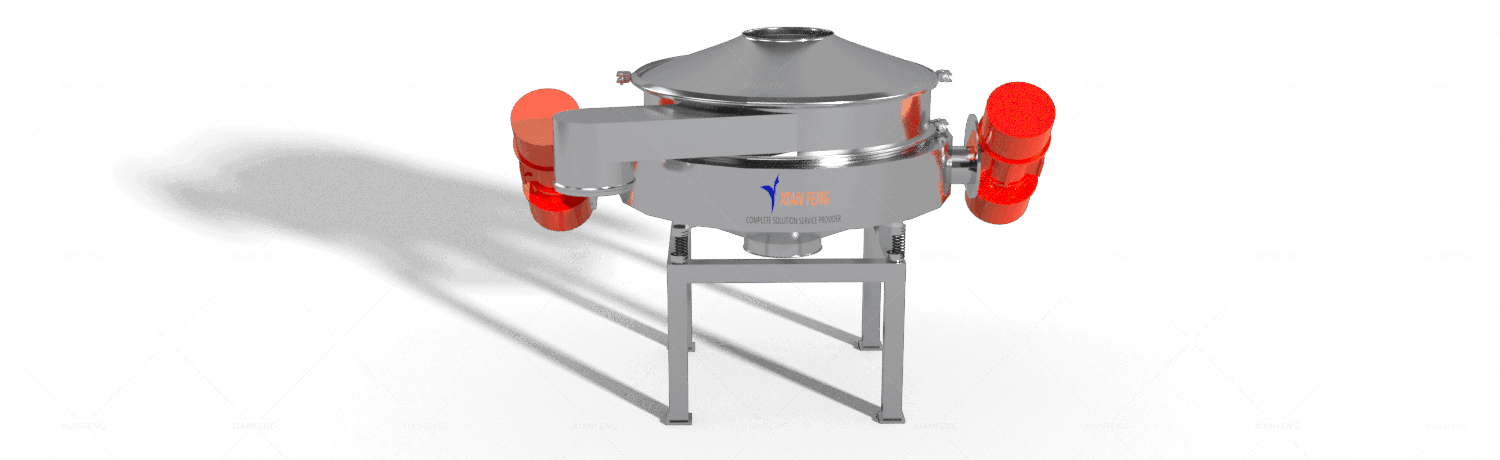

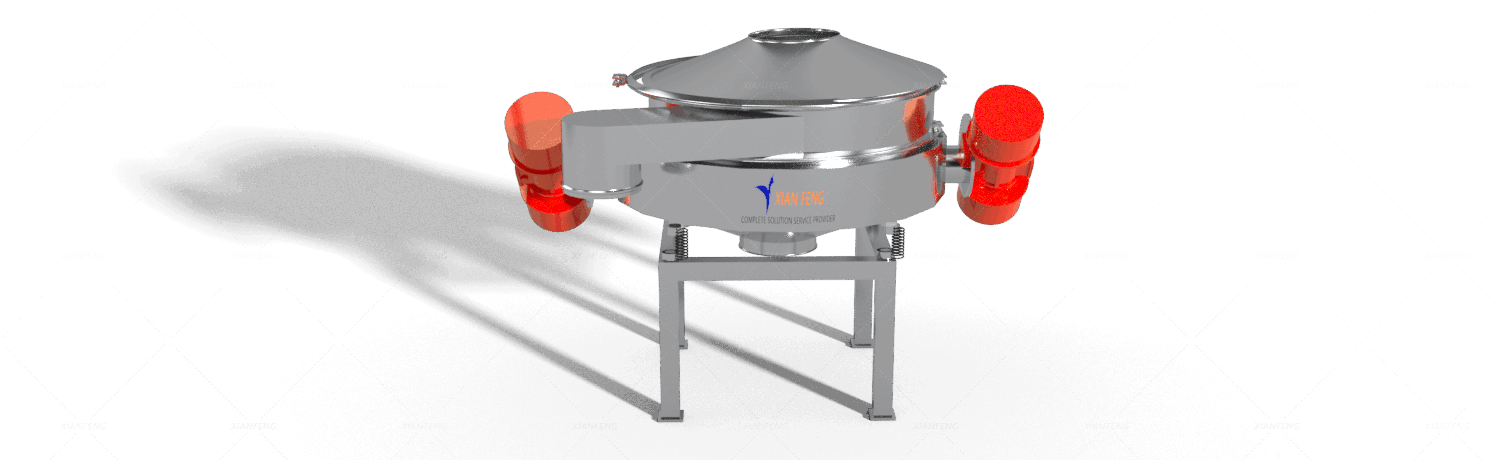

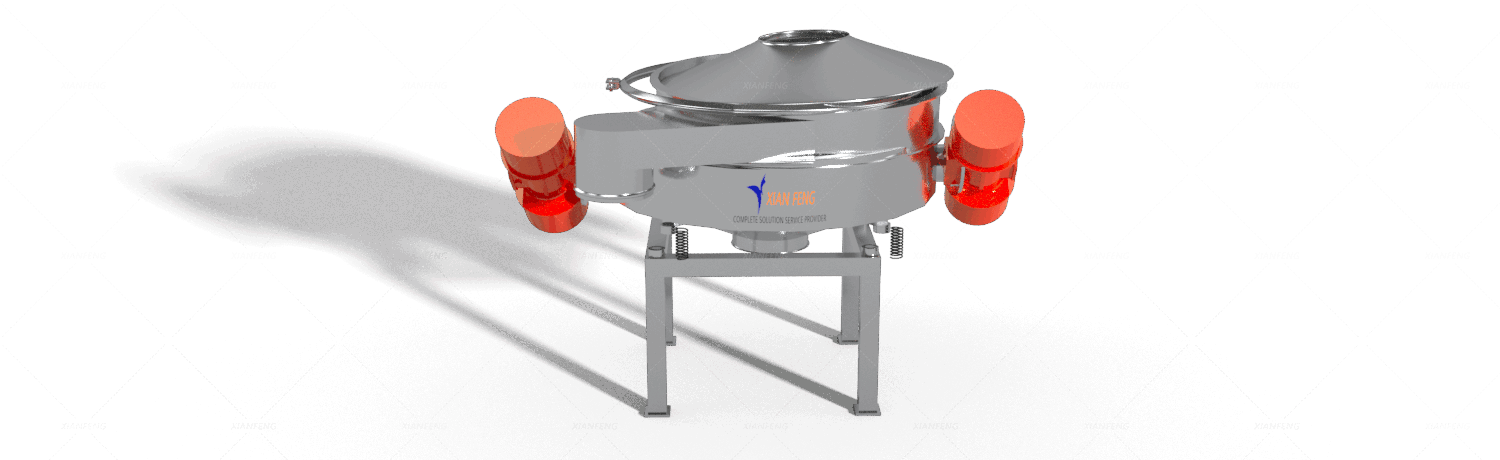

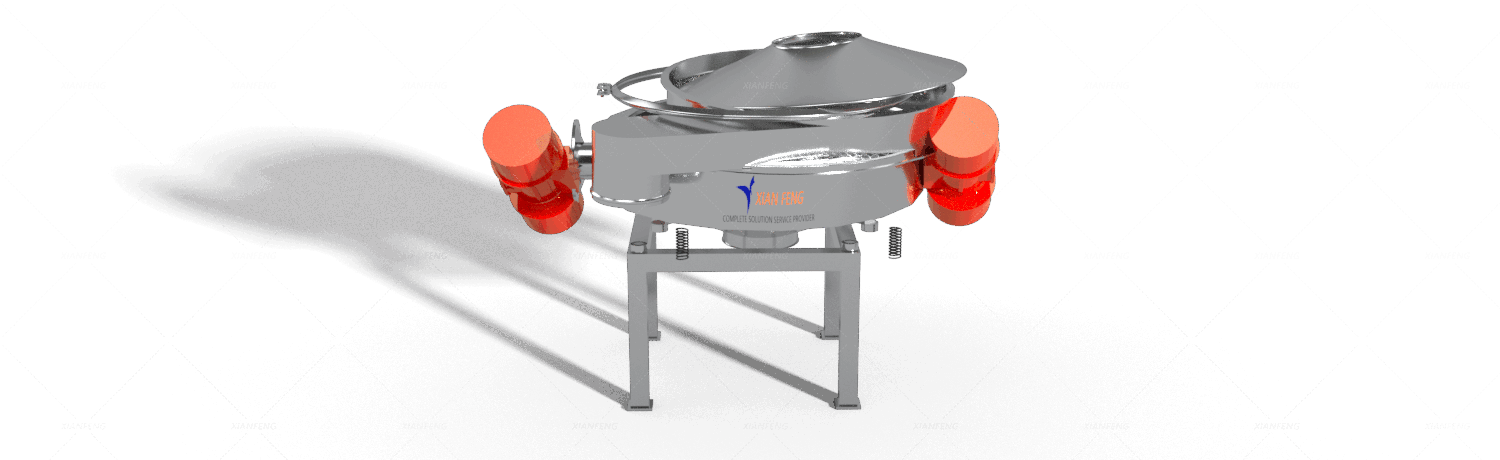

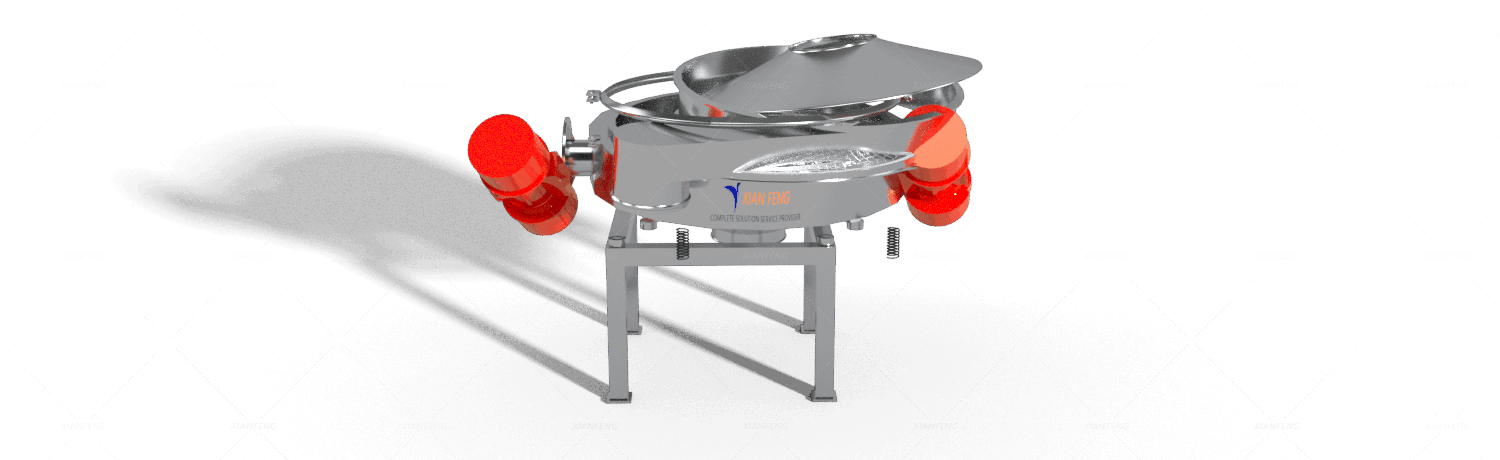

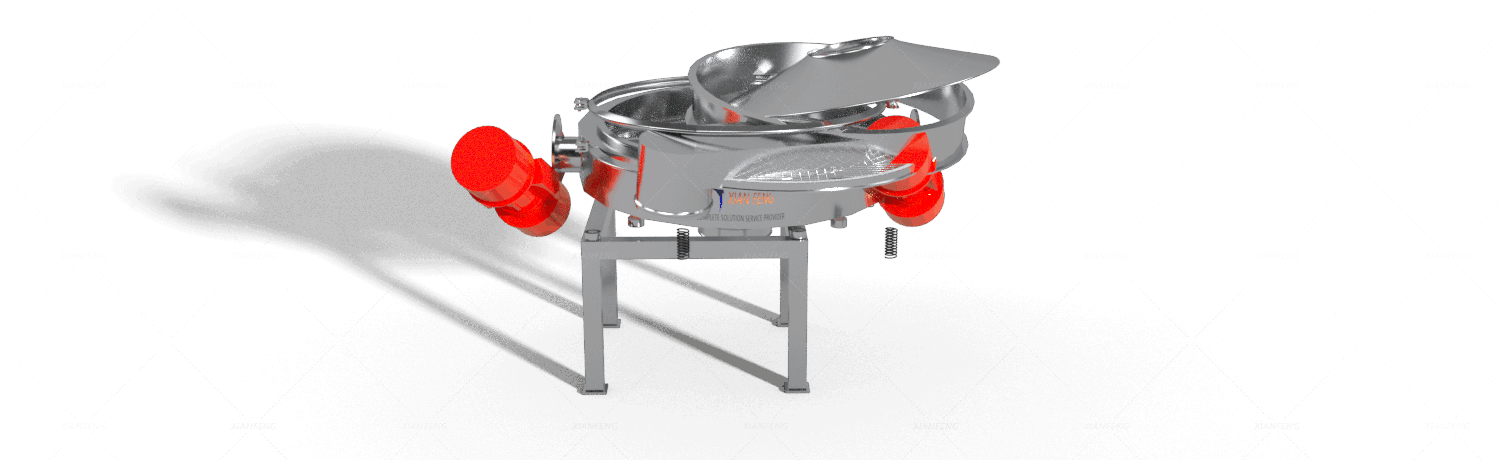

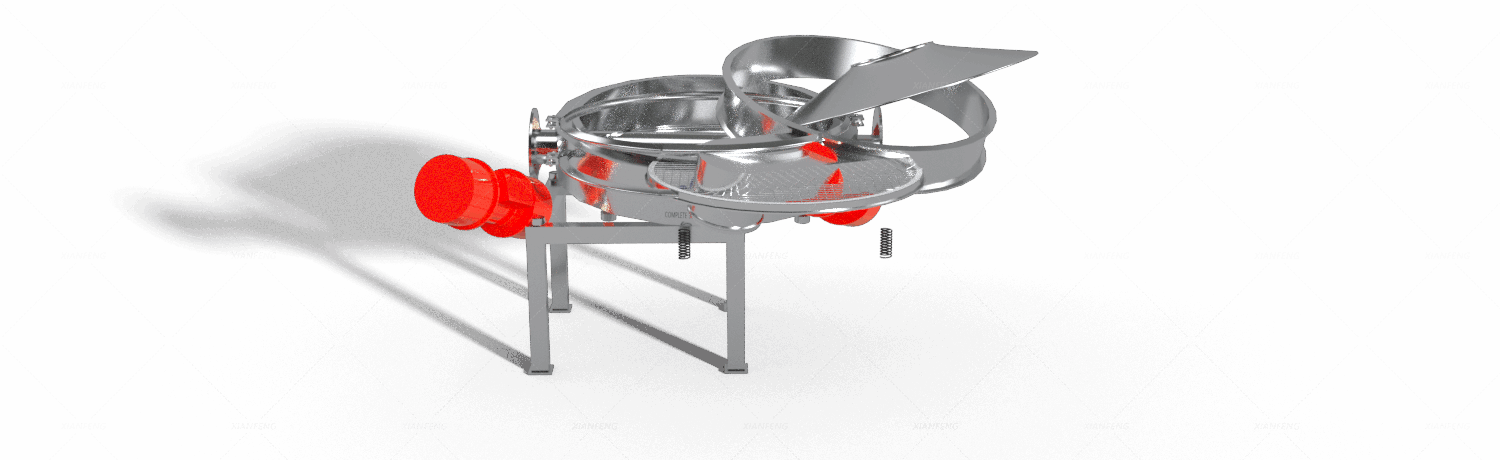

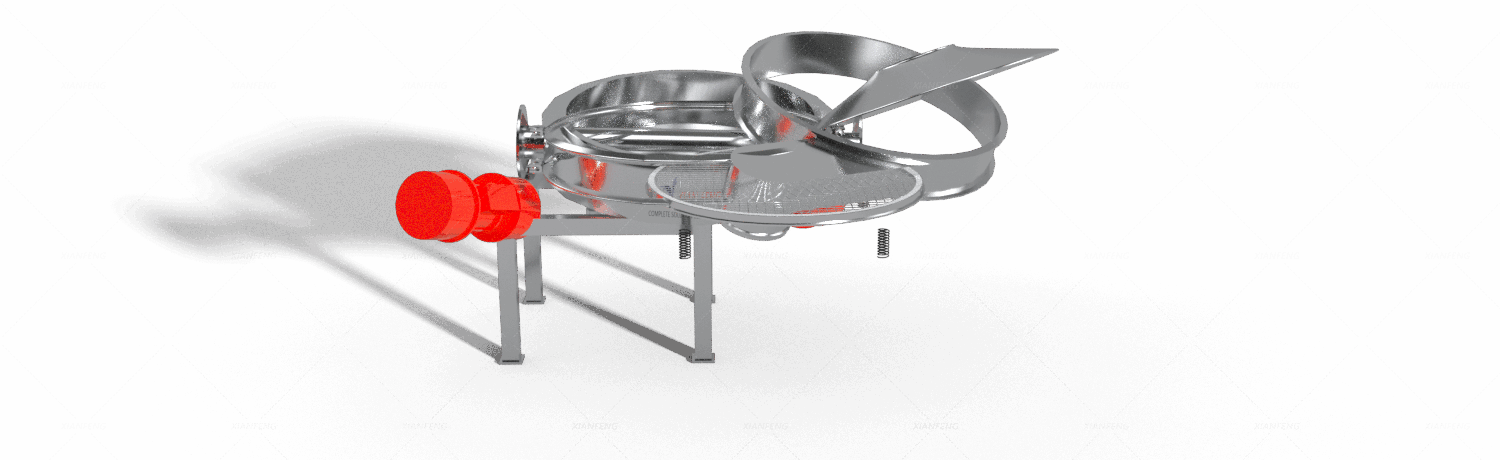

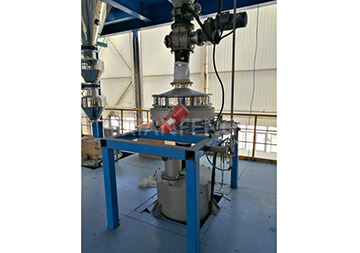

The industrial floor sifter machine, also known as the direct discharge vibrating screen or discharge vibrating screen, is an circular vibratory screener designed for powder and fine particle materials. Its core advantage lies in achieving rapid discharge and large processing capacity screening through structural innovation. Compared with traditional rotary vibrating screens, its unique "vertical feeding and discharging+bottom straight discharge" design reduces the residence time of materials on the screen surface by more than 50%, and the processing capacity can reach 2-5 times that of ordinary circular screens. The single-layer screen design is particularly suitable for coarse screens, usually using mesh holes within 30 mesh.

In application scenarios, direct screening is widely used for impurity removal of food raw materials such as flour and starch, rough screening of chemical products such as laundry detergent and metal powder, and precision grading in the pharmaceutical and non mining industries due to its high efficiency. Its compact structure and low height are suitable for production environments with limited space, and it can directly connect production lines to achieve 24-hour automated operations. data-type="page" data-id="2713" target="_blank" rel="noreferrer noopener">

iron powder, copper, manganese, quartz sand, coke, fluorite powder, talc powder, feldspar powder, etc

river sand, machine-made sand, crushed stone, cement, soda ash particles, gypsum powder, ceramic raw materials, etc

Baking Soda, Fertilizer Particles, Plastic Particles, Rubber Particles, Resin Powder, Ceramic Powder, Lithium Battery Materials, etc

grain granules, flour, sugar, salt, milk powder, starch, dehydrated vegetable granules, crushed nuts, coffee beans, etc

Chinese medicine powders, Chinese medicine granules, Western medicine raw material powders, medicinal excipients, etc

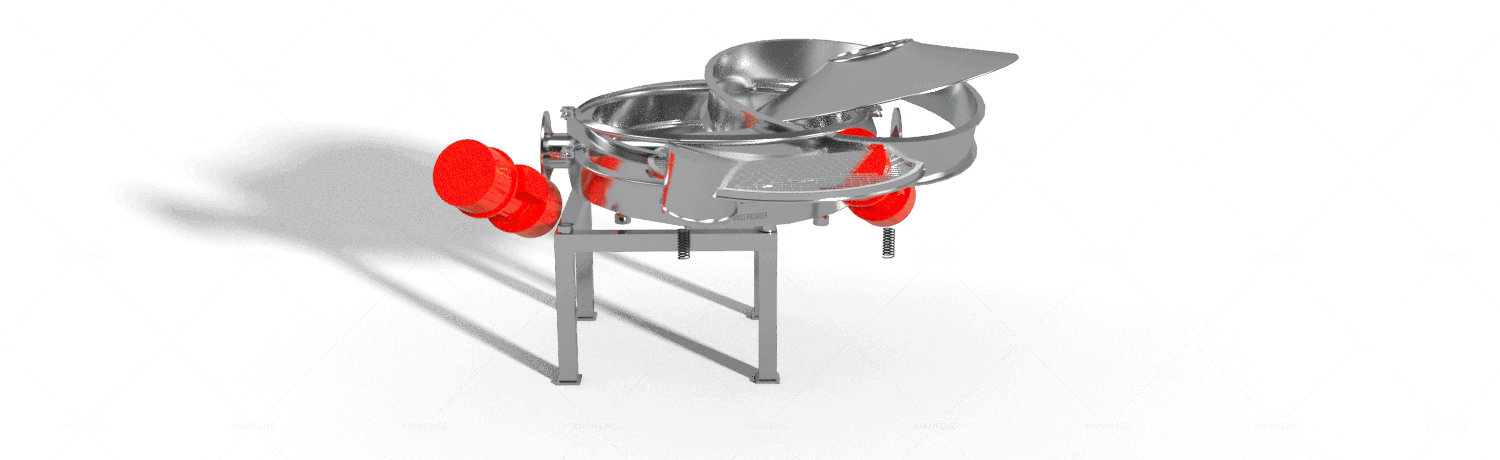

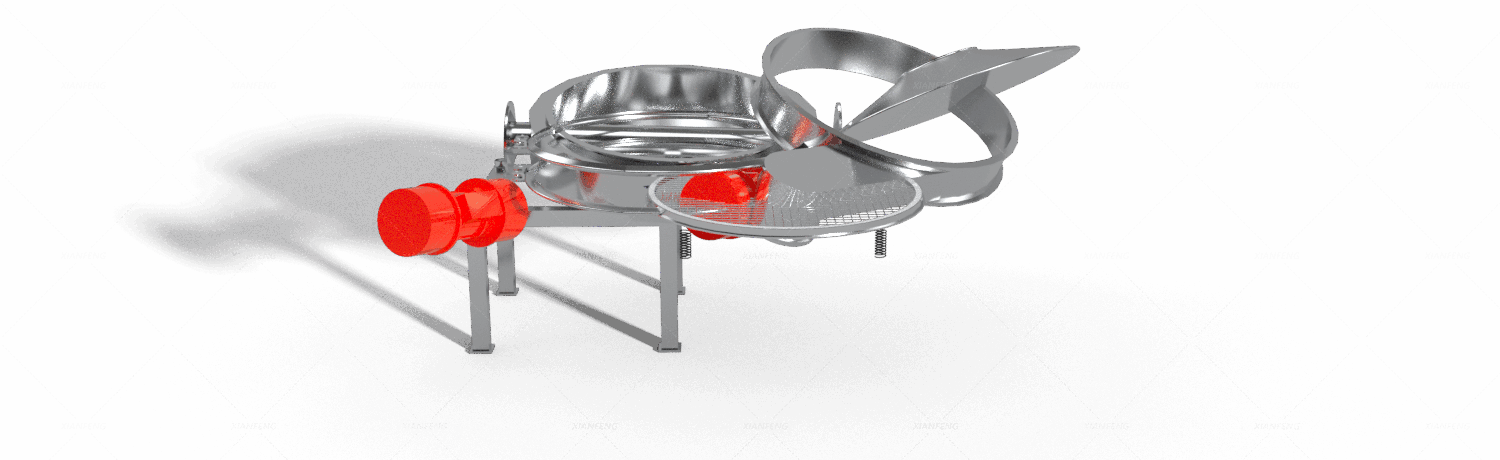

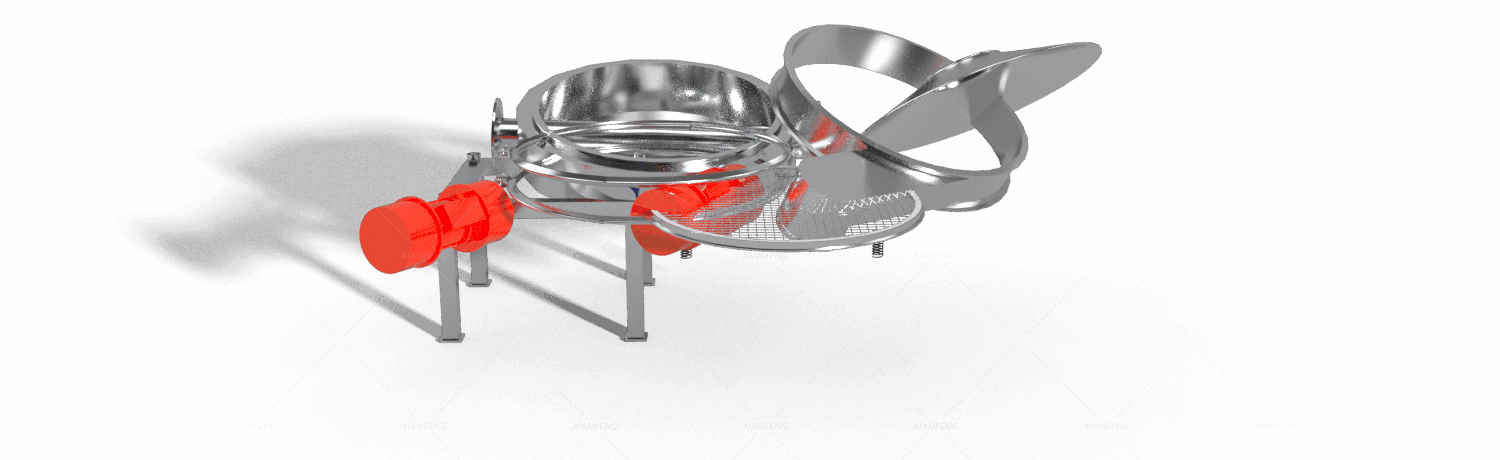

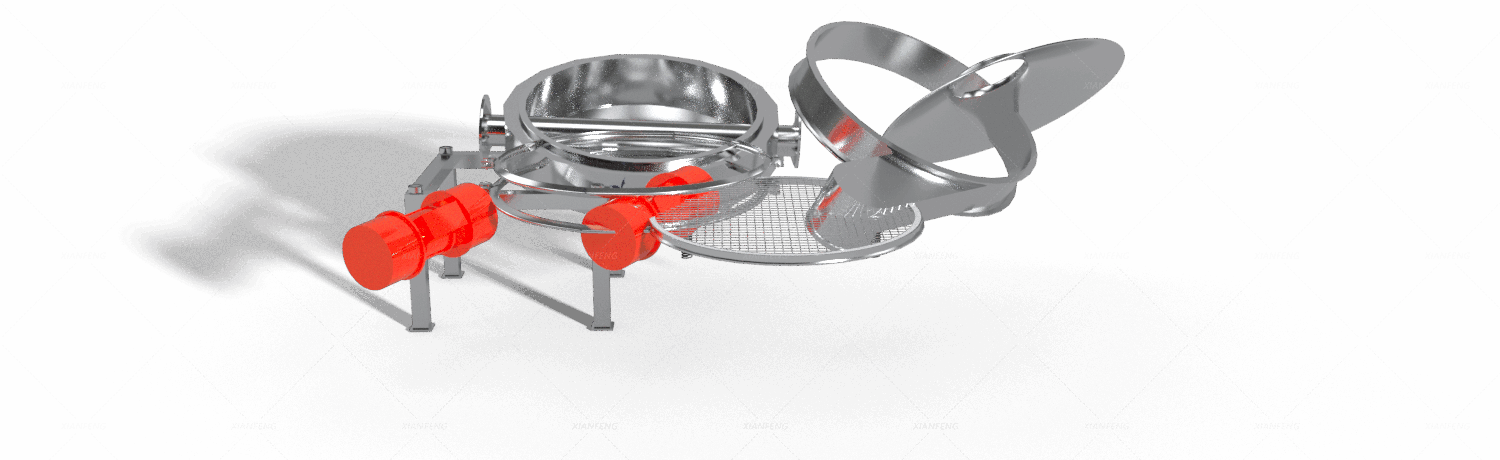

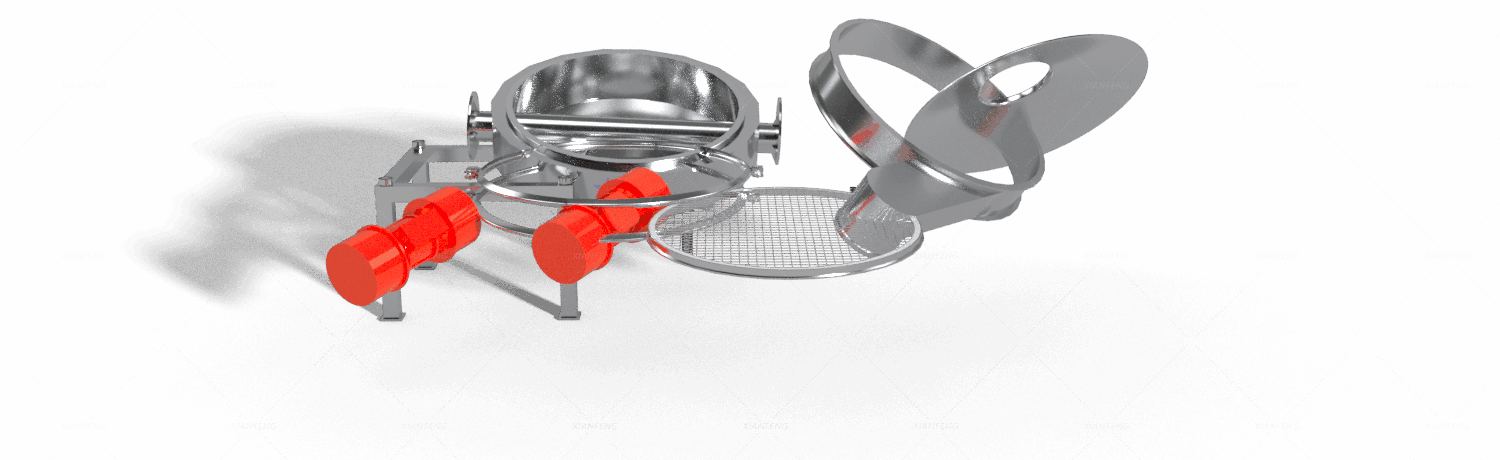

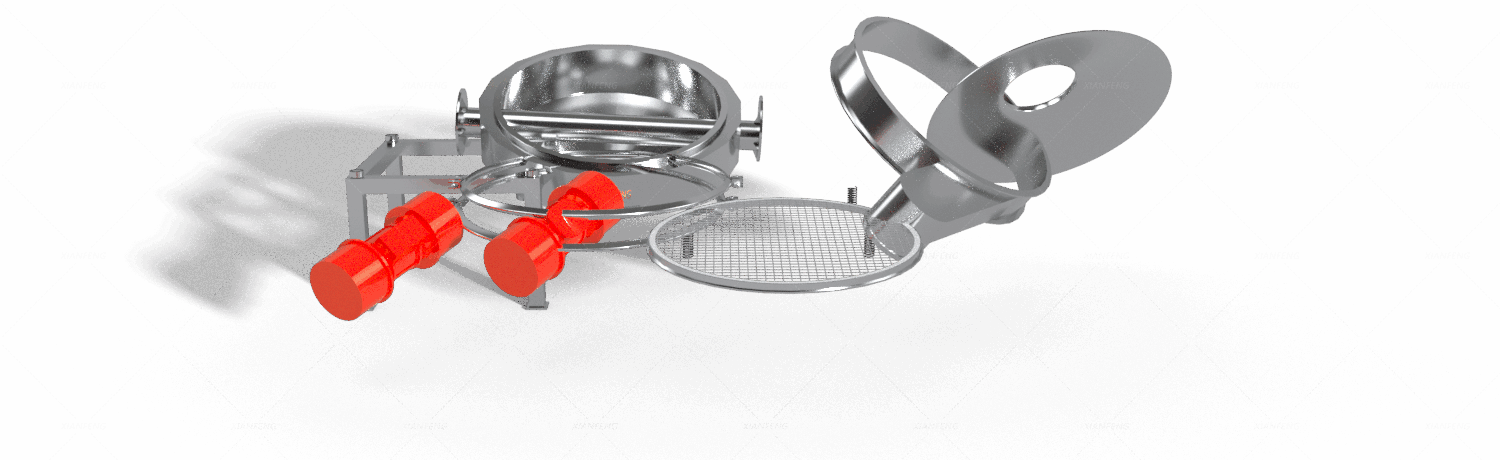

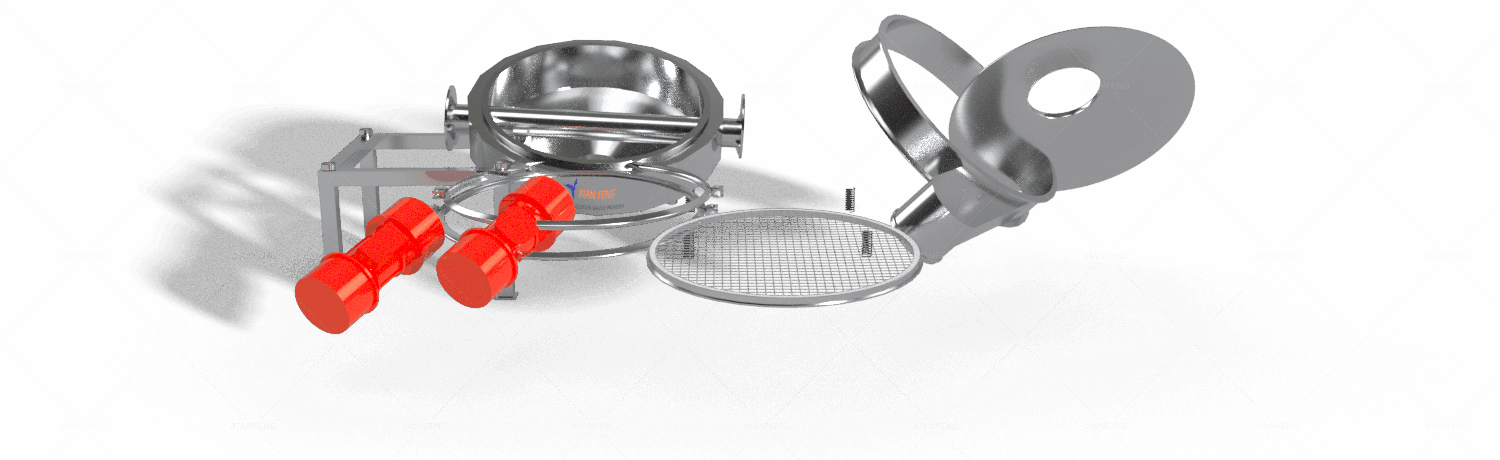

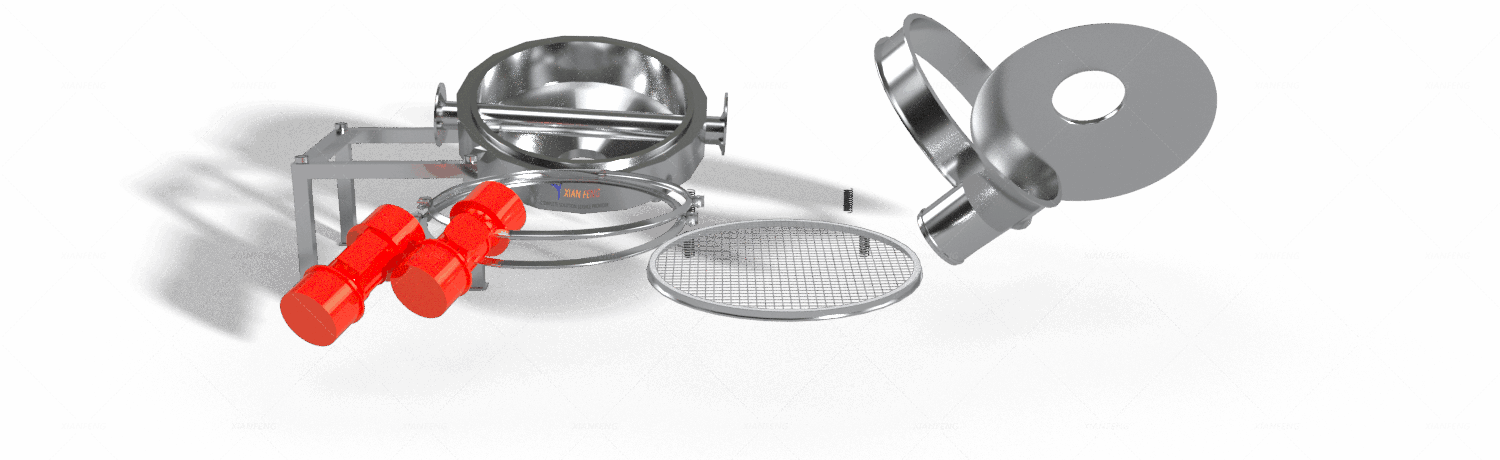

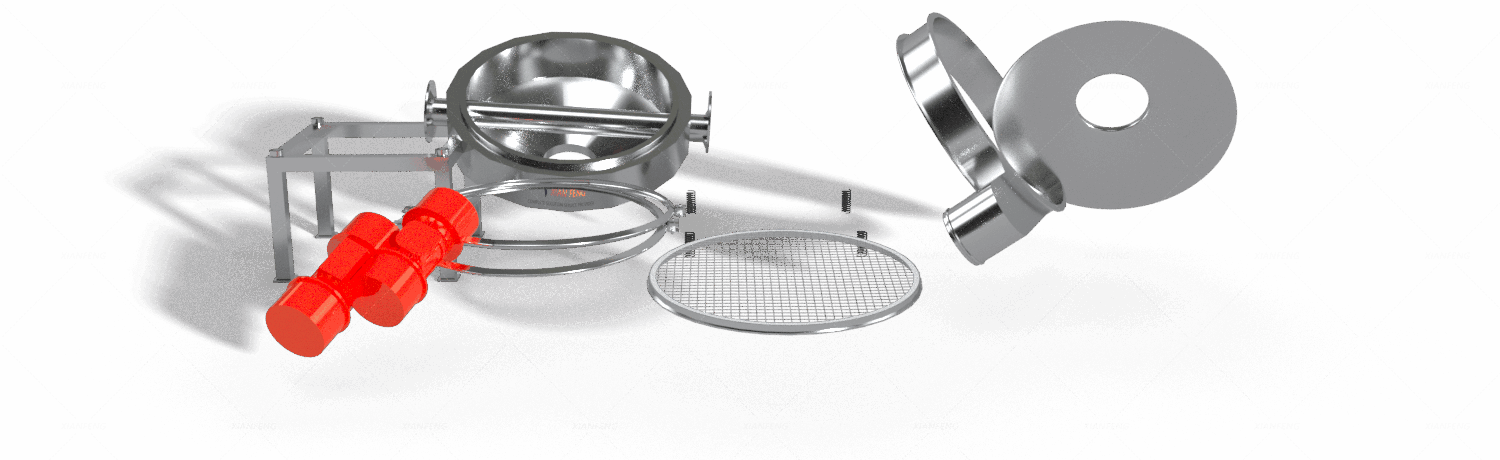

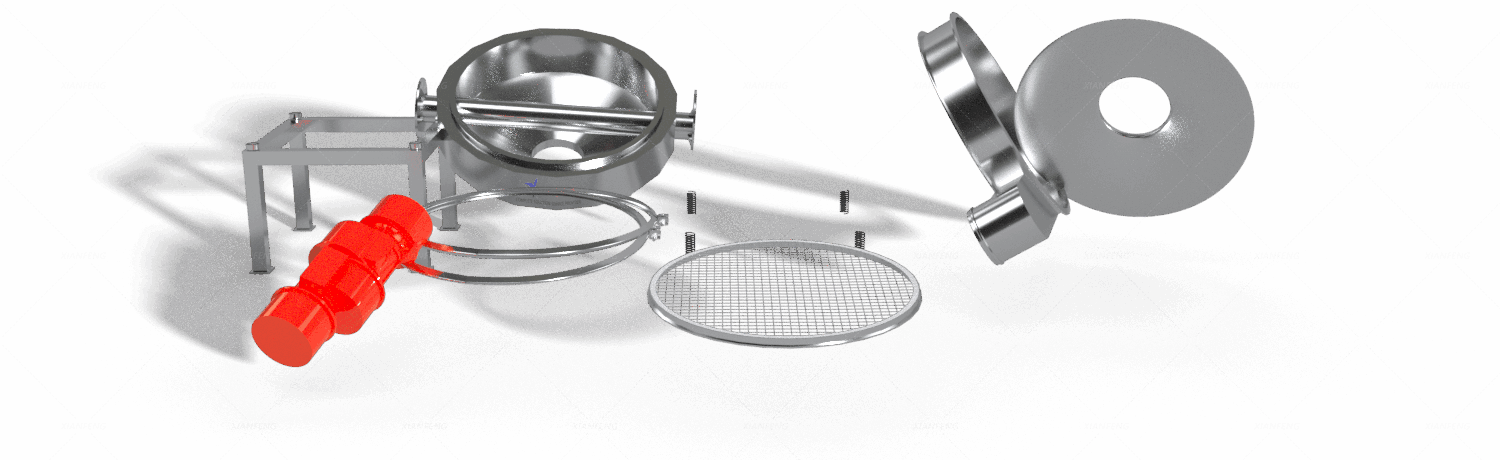

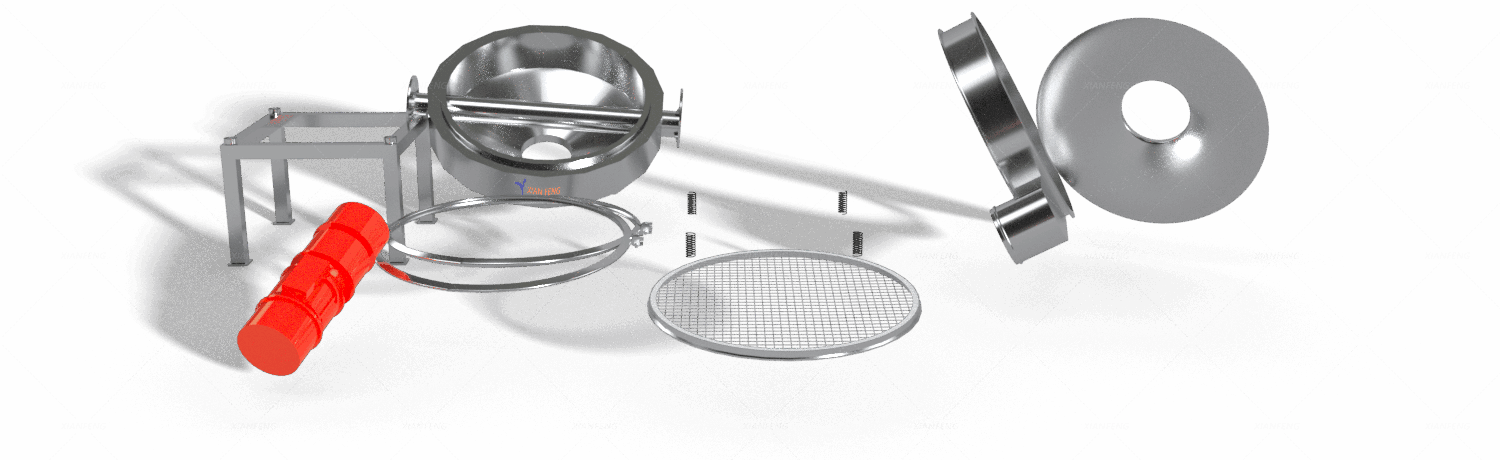

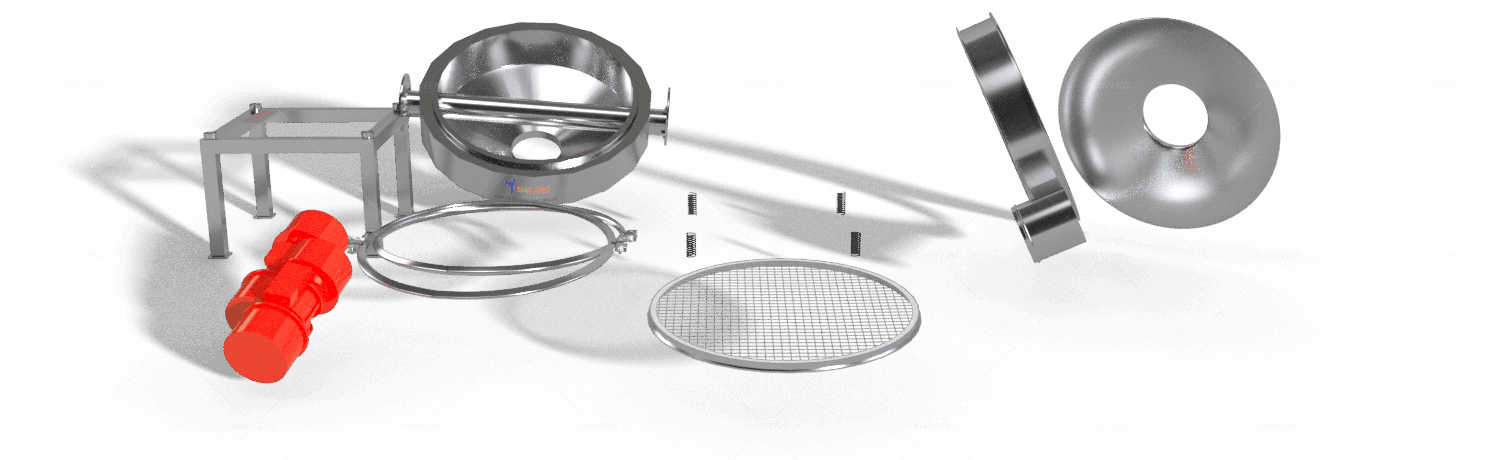

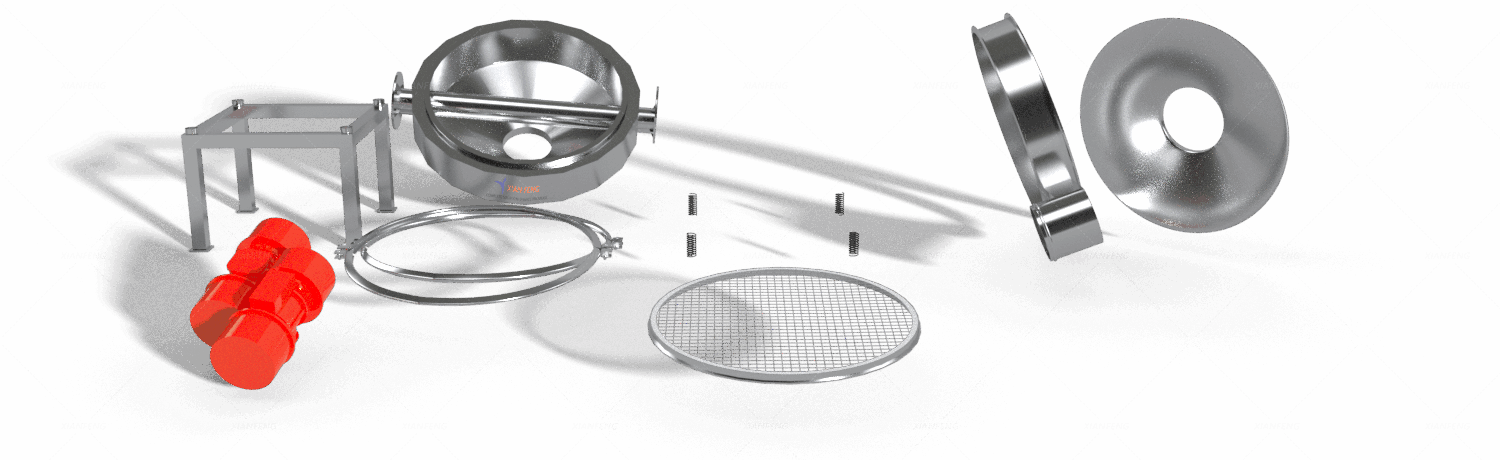

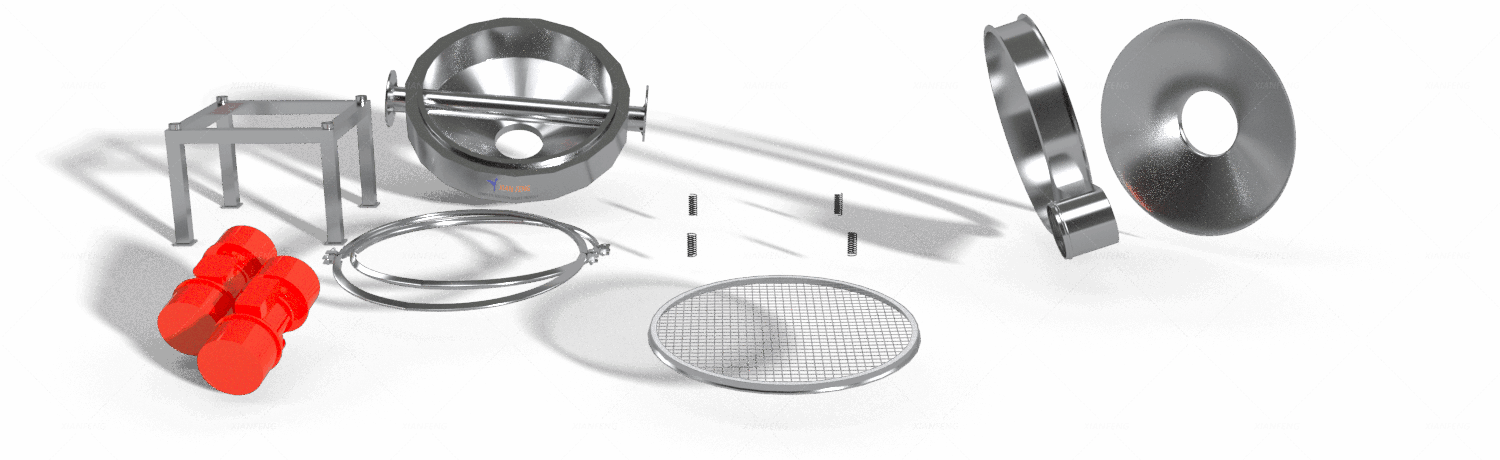

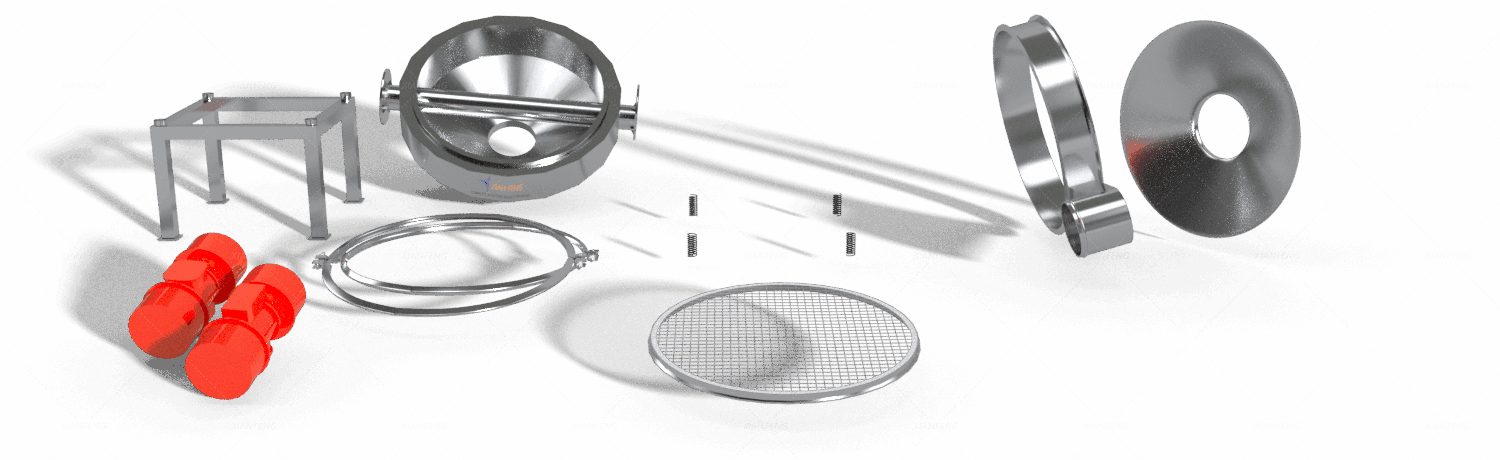

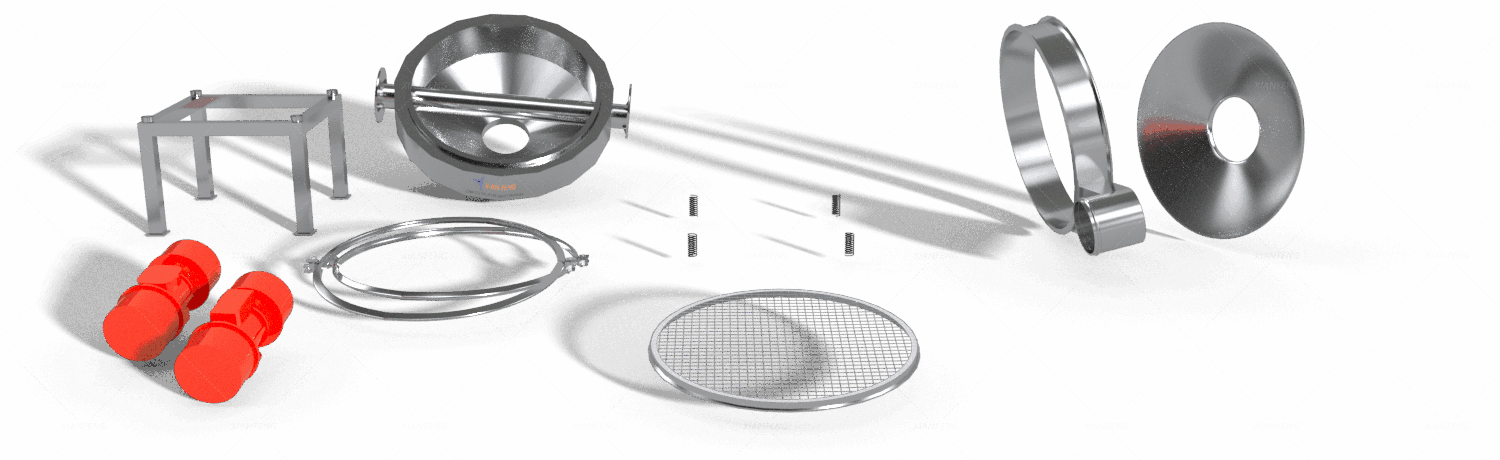

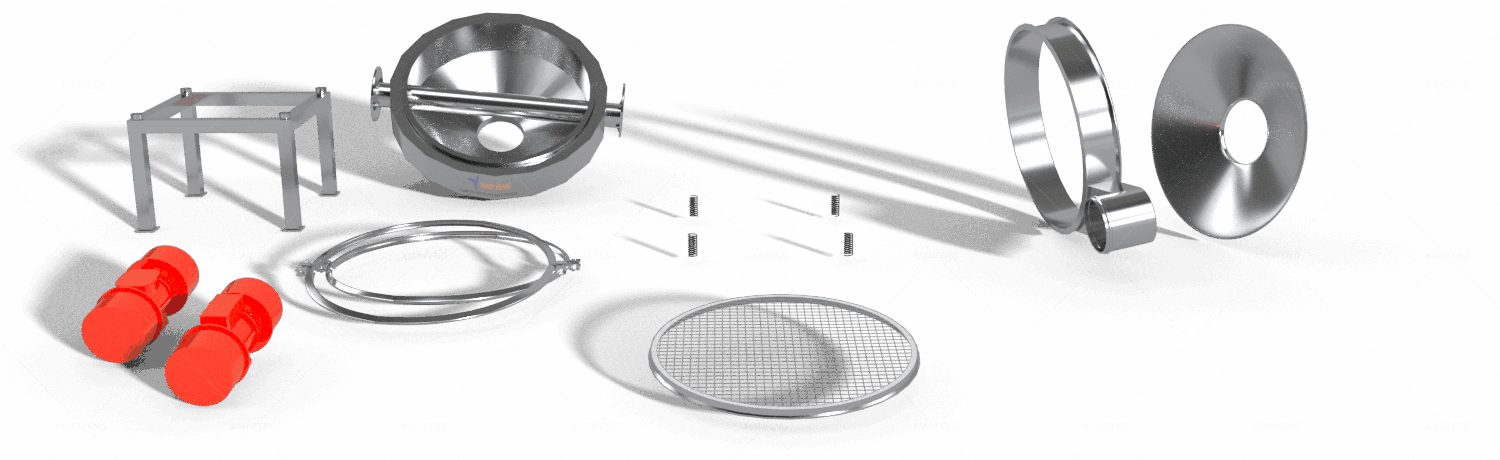

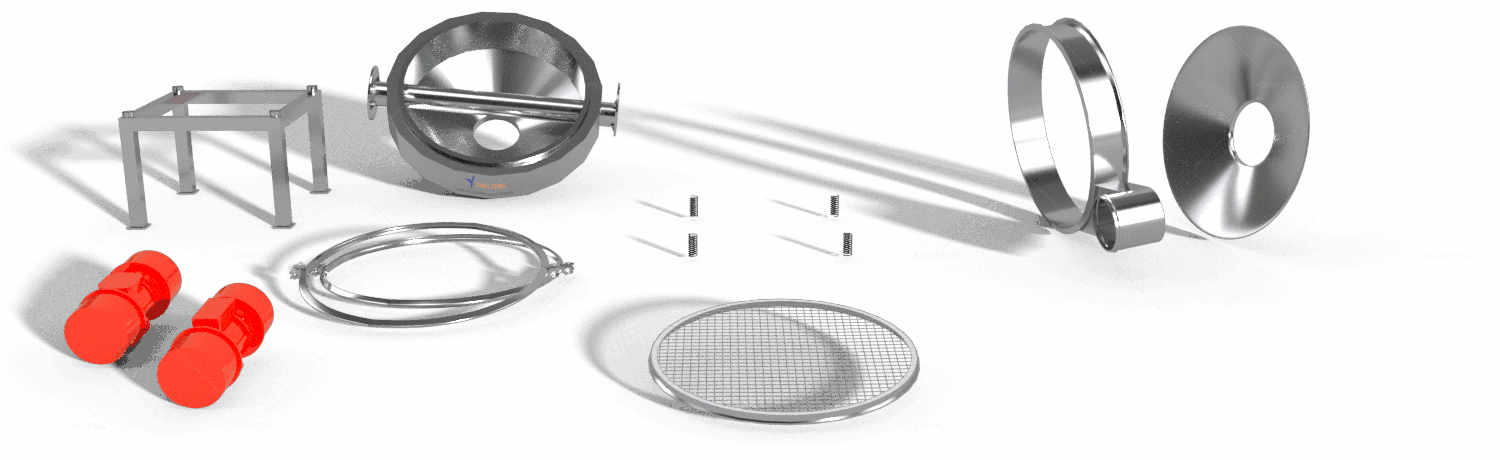

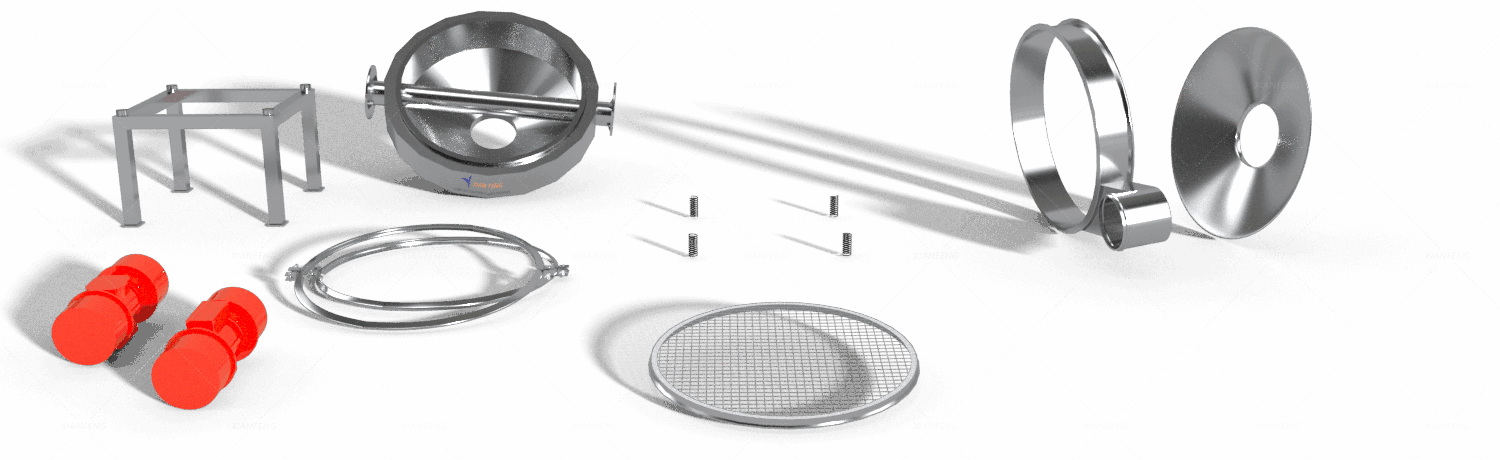

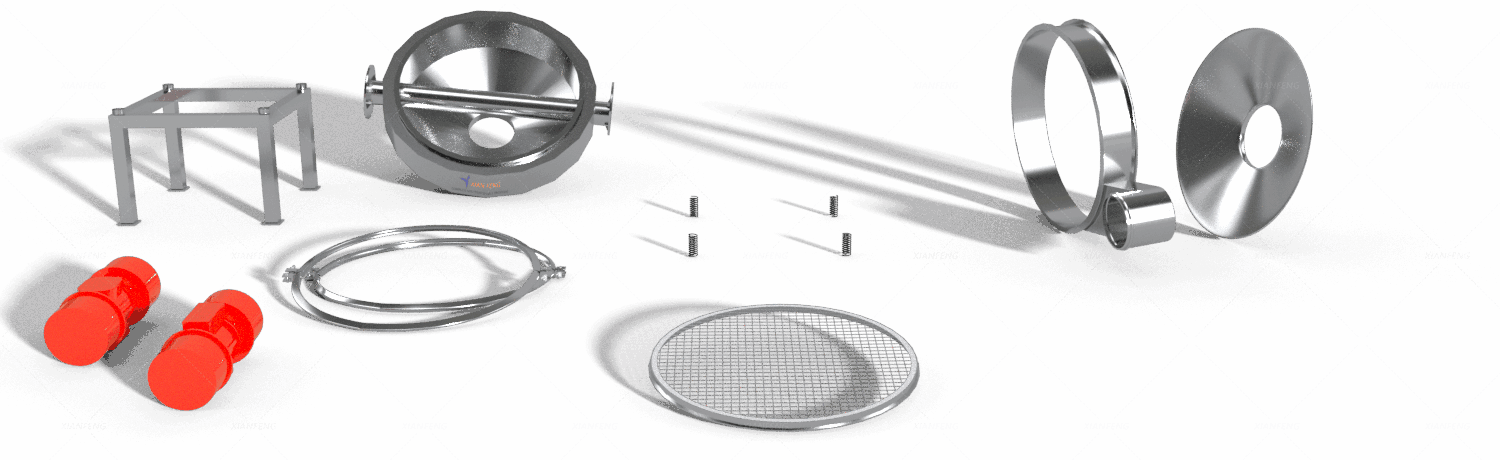

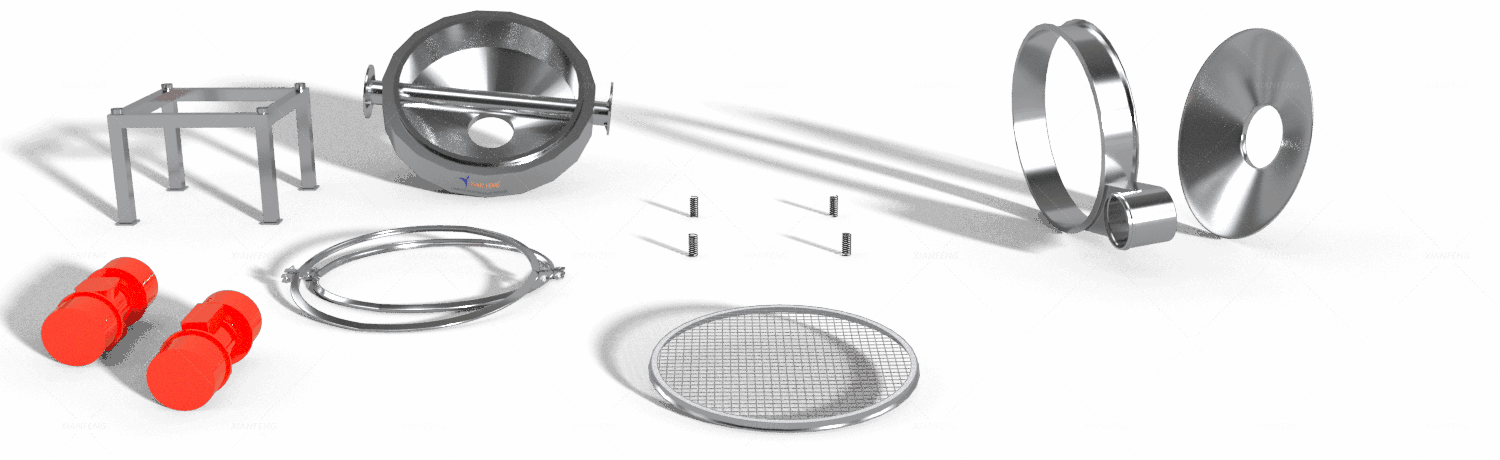

Feed inlet and surface treatment process

Screen mesh and Clamp Ring

Screen frame

Motor

Vibrating body

Base and components

Optional dust cover can effectively prevent dust from flying.

It can be equipped with a feeding buffer device to prevent material from tipping in and damaging the screen mesh.

Optional surface treatment processes include sandblasting, stainless steel wire drawing, polishing, and carbon steel painting.

Optional quick opening device or bolt fixation.

Provide customer requested mesh size according to requirements.

Paired with a high elasticity ball to clear the net more efficiently.

Thickened sieve frame with fish scale pattern welding process, high strength, preventing cracking. Internal polishing without dead corners, easy to clean without material storage or leakage.

The discharge port is finely polished without burrs to prevent material contamination.

The use of food grade pharmaceutical grade processes and related accessories can meet the requirements of food grade pharmaceutical grade material processing and production standards.

XIAN FENG adopts imported Ouli Wolong motors, which have low energy consumption, high efficiency, and low faults.

Explosion proof motors can be customized as needed to meet different national production safety standards.

Adjustable angle control amplitude to meet different precision production requirements.

By using high-strength and thickened vibrating bodies to prevent cracking, precise adjustment of amplitude transmission loss can achieve higher output.

Smooth internal polishing and quick unloading without jamming.

Assemble high steel single or double springs according to customer requirements to meet different production scenarios.

Bottom vertical discharge design, fast unloading is a specialized and efficient equipment for impurity removal.

Adopting a high-strength rigid structure, it can withstand stress and temperature, resist deformation, and ensure long-term stability of the equipment. We can customize different types or heights according to customer requirements.

The working principle of the equipment is to provide vibration sources through two vibration motors on both sides. By adjusting the phase angle of the eccentric block, an elliptical or vortex motion trajectory is generated, which enables the material to be peeled, dispersed, and sieved under the combined action of centrifugal force and horizontal force. Unqualified materials are automatically discharged along the sieve surface trajectory. The food, pharmaceutical, chemical and other industries generally use 304/316L stainless steel materials to meet industry production standards and special material requirements for corrosion resistance, alkali resistance and other characteristics.

mainly used to prevent powder from overflowing during screening.

Adopting a single-layer screen design, materials smaller than the aperture are discharged from the bottom, and materials larger than the aperture are discharged from the upper outlet. It is often used for impurity removal when the material on the screen does not exceed 10%. Paired with punched pallets and elastic balls to clean the screen mesh for efficient screening.

XIAN FENG adopts imported Ouli Wolong vibration motors, which are divided into single motor and dual motor configurations to meet different customer needs. The amplitude and frequency can be adjusted by adjusting the angle of the swing block.

Quick opening structure or bolt fixing structure can be selected as needed to fix the screen frame.

Made of high steel material, single or double spring support is selected to effectively reduce resonance and prevent impact on the ground.

Adopting thickened high-strength vibration body and rigid welding process to prevent vibration cracking and ensure long-term continuous production work.

High steel material base is used, and different types of bases are customized according to customer needs.

Milk powder impurity removal

Monkey bread flour impurity removal

Removing impurities from medicinal powder

Lutein impurity removal

| Model | Power(kw) | Speed(r/min) | Screen Dia. | Screen area(m²) |

| XFZP-600 | 2*0.06 | 1450 | φ560 | 0.22 |

| XFZP-800 | 2*0.08 | 1450 | φ760 | 0.4 |

| XFZP-1000 | 2*0.25 | 1450 | φ950 | 0.65 |

| XFZP-1200 | 2*0.4 | 1450 | φ1150 | 0.95 |

| XFZP-1500 | 2*0.45 | 1000 | φ1450 | 1.5 |

Suitable materials:

Particles: plastic particles, fertilizer particles, feed particles, ore particles (particle size 0.1mm-50mm);

Powder type: cement, flour, starch, chemical powder (humidity ≤ 8%, no strong viscosity);

Slight mixed materials: such as stones in grains, impurities in plastic particles, and lumps in pharmaceutical powders.

Not suitable for materials:

Strong adhesive materials: such as wet mud and paste like materials (which are prone to sticking to the screen surface and discharge outlet, causing blockage);

Oversized materials (particle size>1/5 of the sieve diameter): prone to getting stuck at the feed inlet or damaging the sieve mesh;

High temperature corrosive materials (temperature>100 ℃ or strong acid-base): detailed communication is required to confirm whether they are suitable;

Our direct discharge vibrating screen has passed CE (European Union), ISO9001 (Quality System), and relevant national level technical patent certifications. Corresponding certification documents can be provided according to requirements to ensure compliance with entry requirements, without worrying about quality standards. The whole machine comes with a one-year warranty (excluding consumable parts). During the warranty period, if there is no human damage, free replacement and repair will be provided.

Common preprocessing connection equipment includes: ① Material bin/storage tank (used for temporary storage of materials, stable feeding, and adaptation to granular and powder materials); ② Spiral conveyor/bucket elevator (used for long conveying distances, spiral conveyor is suitable for powder/small particles, bucket elevator is suitable for large particles/block materials); ③ Crusher/grinder (when the particle size of the material is too large, it is crushed first and then screened, such as ore and plastic blocks); ④ Vibration feeder (precise control of feeding amount, avoiding screen machine overload, suitable for easily clumped materials), etc

The post-processing equipment includes: ① Packaging machines (in the food/chemical industry, such as powder filling machines and granule packaging machines); ② Blender (when mixing with other materials, such as feed production); ③ Conveyor pipeline/fan (pneumatic conveying to the next process, suitable for lightweight powders); ④ Storage tank/finished product warehouse (temporarily stored for further processing or outbound), etc

Due to its compact size, it can also be directly embedded into other equipment for use, such as ton bag feeding stations, dust-free feeding stations, etc.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.