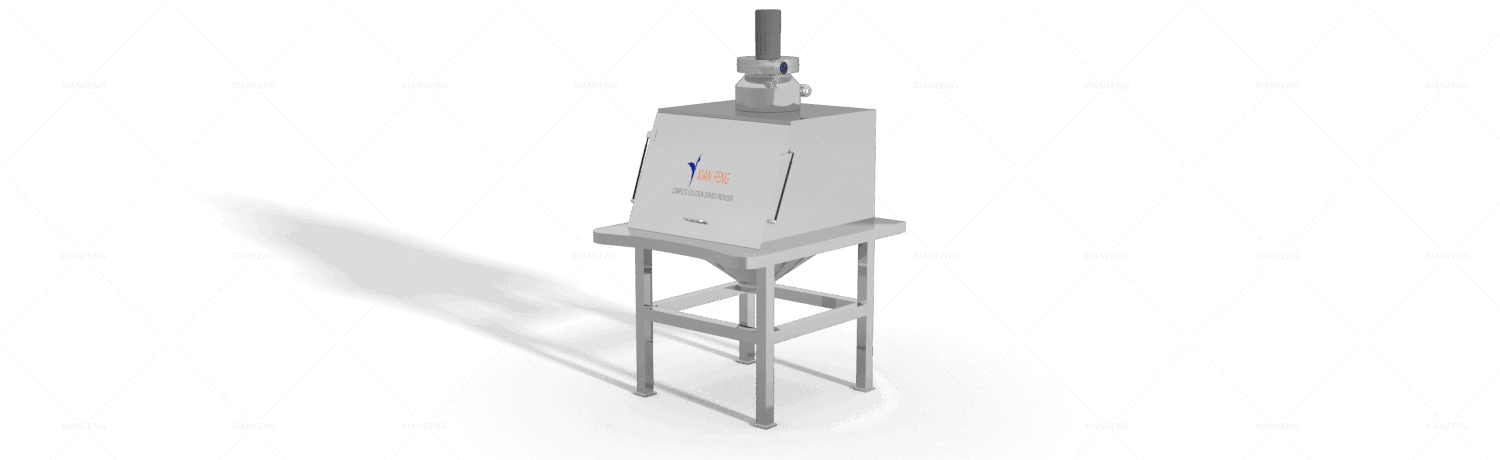

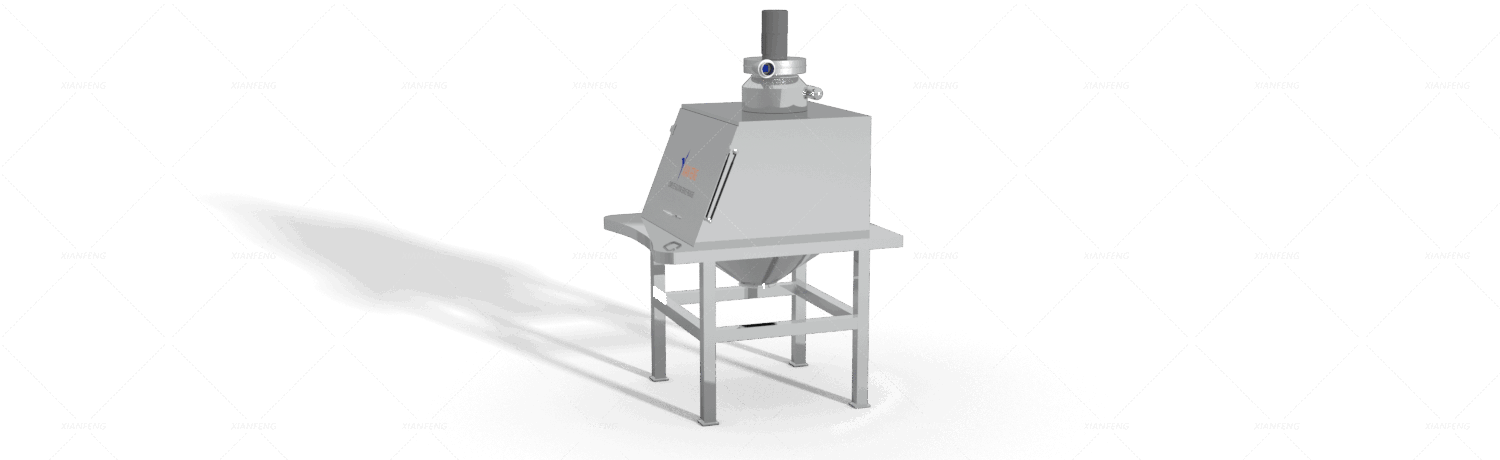

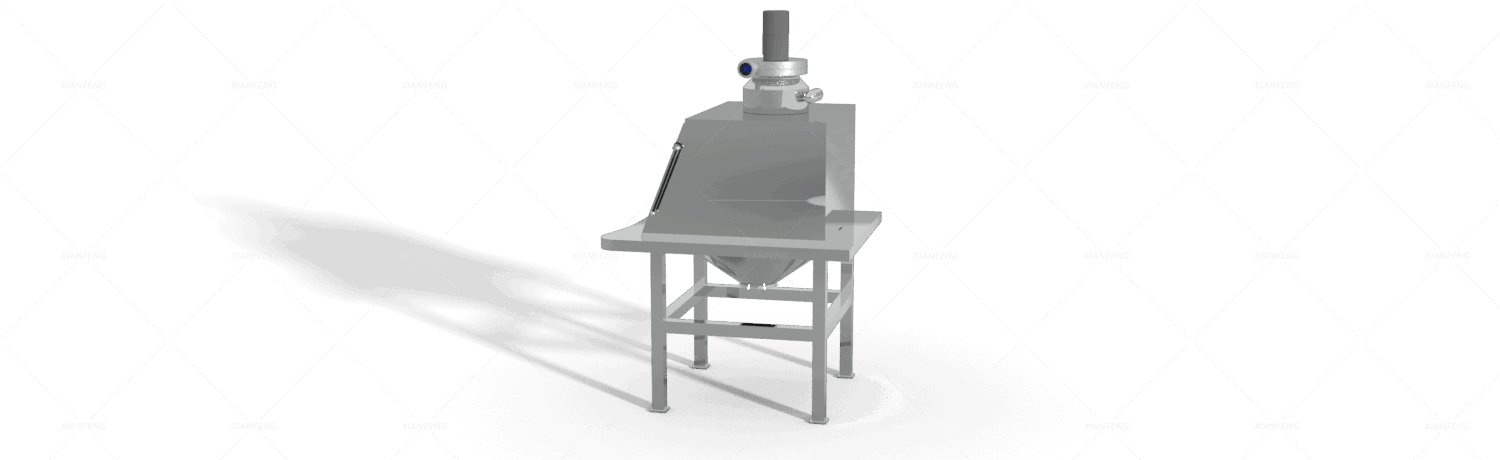

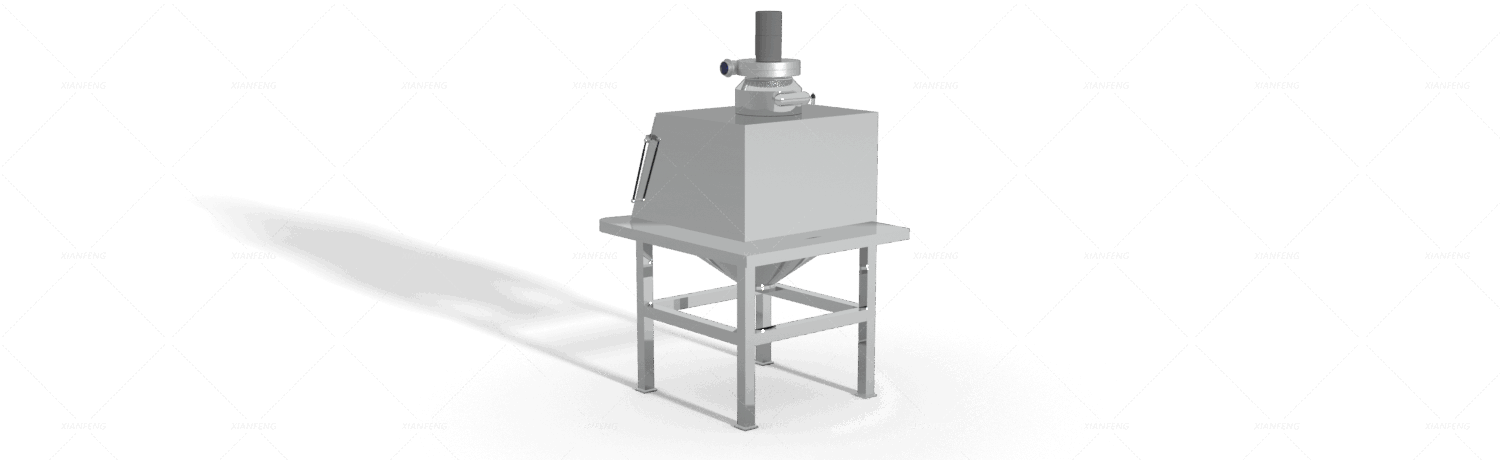

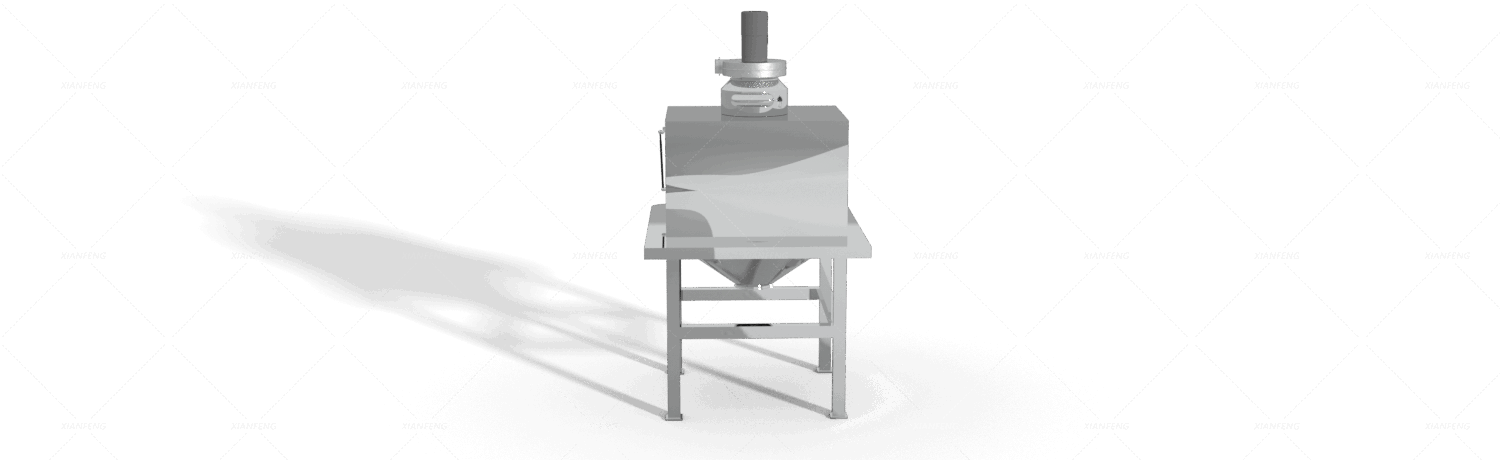

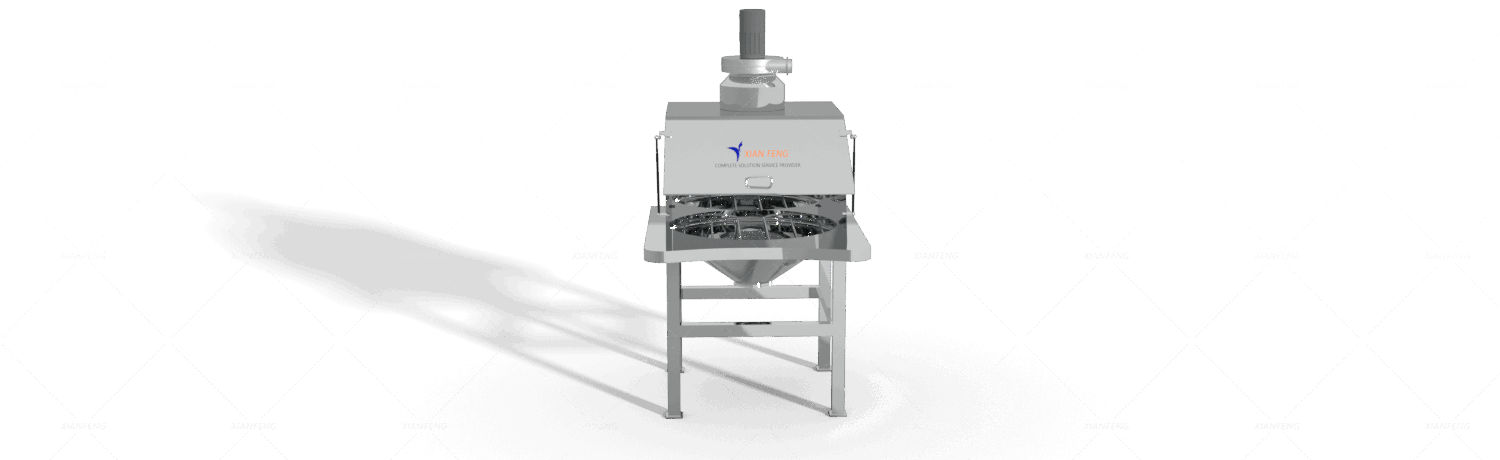

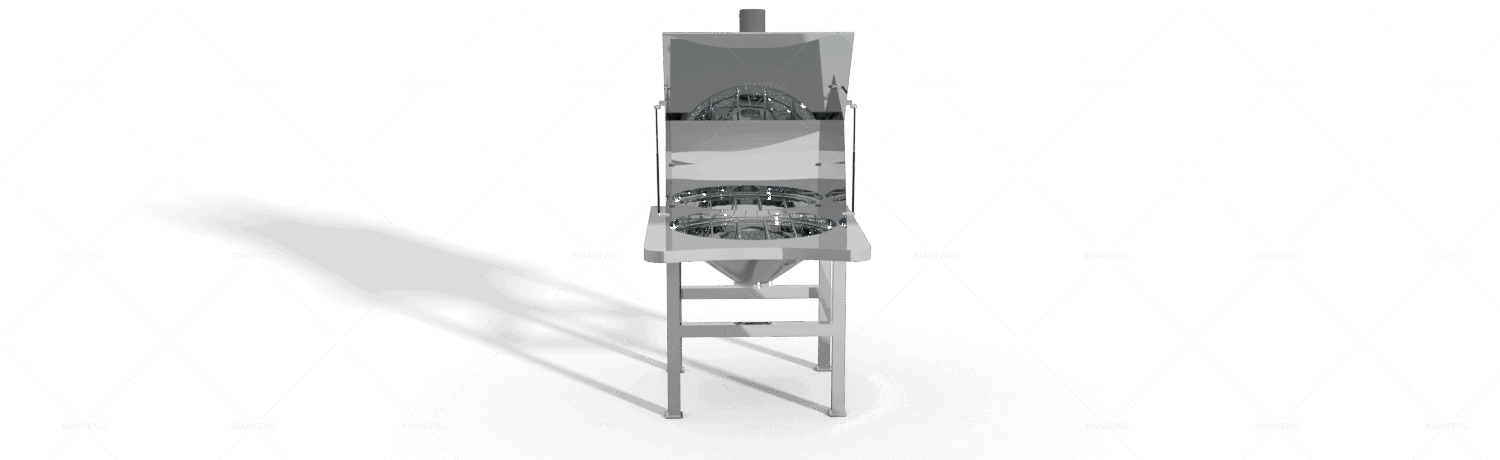

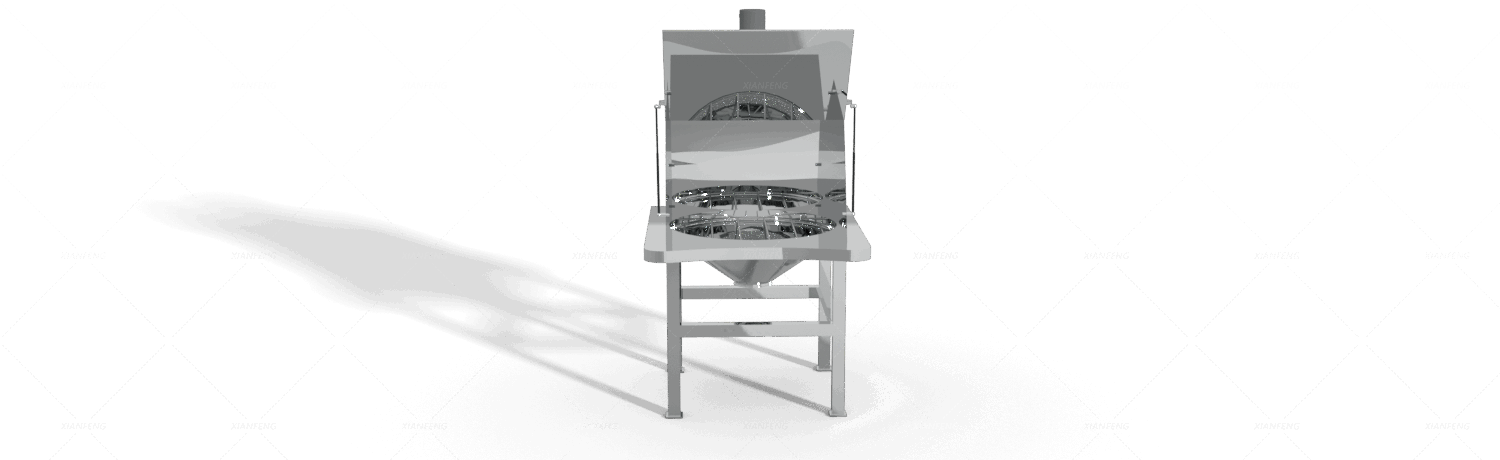

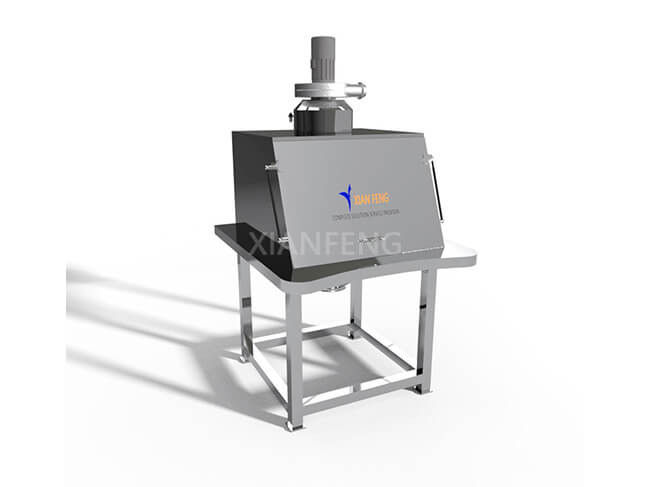

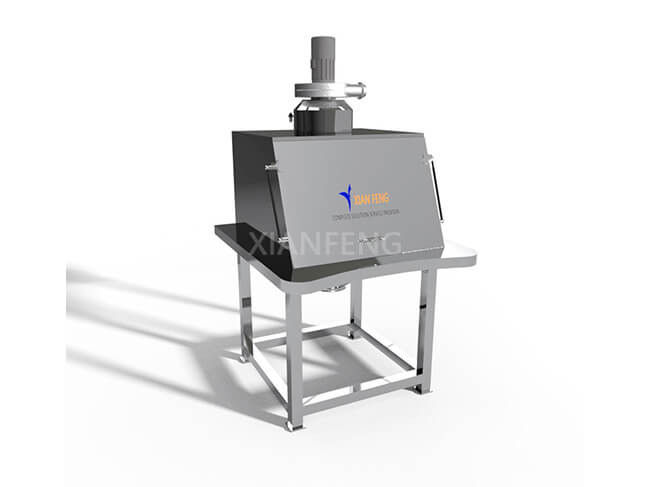

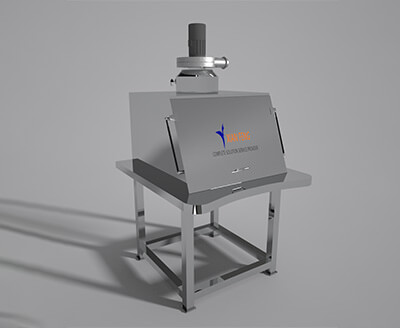

Bag dump station are a closed feeding equipment designed specifically for industrial production of powder and granular materials, consisting of feeding platforms, unloading bins, dust removal systems, vibration screen, and other components. Mainly used in industries such as pharmaceuticals, food, chemicals, and new energy, Made of 304/316L stainless steel material,it achieves dust-free operation through negative pressure suction and multi-stage filtration technology, effectively solving the problems of dust pollution, material loss, and safety hazards in the traditional manual small bag feeding process.

grain, flour, corn starch, cassava starch, milk powder, sugar powder, edible essence, seasoning, coffee beans, cocoa beans, etc

Pharmaceutical raw materials, pharmaceutical intermediates, pharmaceutical excipients, traditional Chinese medicine powders, veterinary drugs, pesticides, etc

Chemical raw material powder, titanium dioxide, calcium carbonate, zinc stearate, polyethylene, graphite powder, lithium iron phosphate, activated carbon, sulfur, etc

copper powder, aluminum powder, silver powder, aluminum oxide, silicon nitride, silicon carbide particles, etc

fly ash, plastic crushing materials, black powder, glass microspheres, etc

cement, gypsum powder, quartz sand, iron ore, limestone, etc

blower

Pulse Backblowing System

Filter element

Hydraulic support and electrical control box

Surface treatment process

Structural combination

Using Roots blower, the wind is strong, stable, reliable, quiet and efficient

Customizable explosion-proof to meet different safety production standards

The pulse blowback device promptly cleans the filter element to prevent blockage, eliminates manual labor, extends the service life of filter consumables, reduces production costs, and ensures efficient operation of the equipment

The oil-water separator fully ensures the normal operation of the pulse blowback device, avoiding the erosion of the filter element by oil, water, etc. in the air.

Filter cartridges are mainly divided into synthetic fiber materials, inorganic fiber materials, metal materials, composite materials, etc. to meet the production environment needs of different industries.

The hydraulic support lever allows one-handed operation, making feeding more convenient.

For special applications, it can be equipped with an explosion-proof electrical control box to meet production safety requirements.

Optional mirror polishing treatment, with a net value of up to 0.3k or surface sandblasting process, beautiful and wear-resistant.

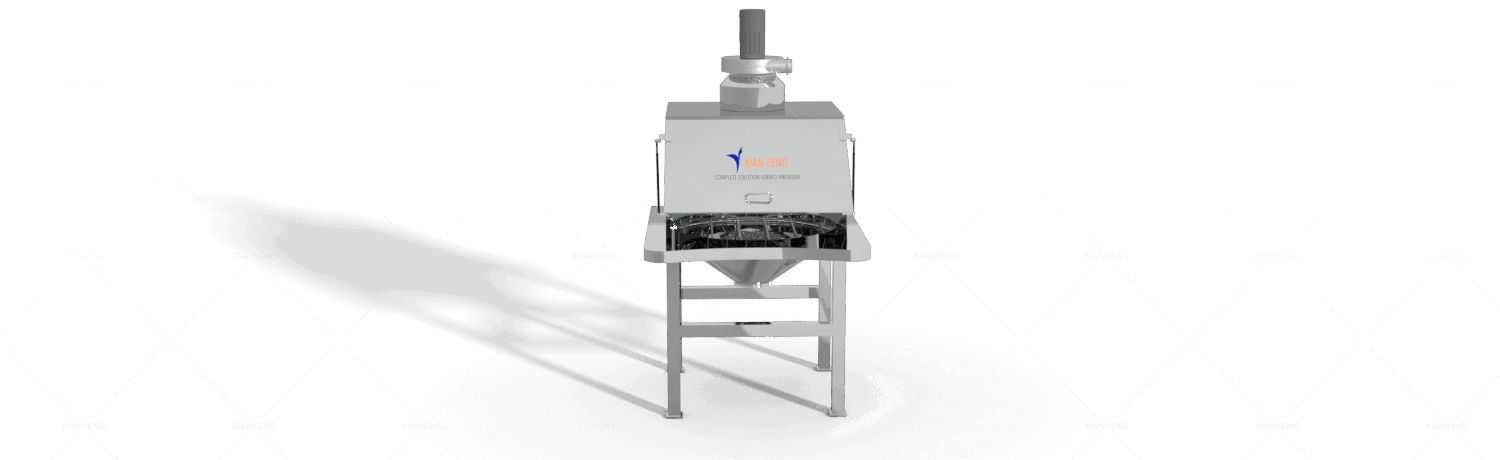

The bottom can be equipped with a vibrating screen to avoid debris that may fall off when manually unpacking or breaking the bag, prevent contamination of materials, and also remove clumped materials.

The bottom can be equipped with a buffer silo and combined with a suction adapter to complete material conveying.

The bottom can be directly combined with a circular vibrating screen to achieve fine screening of small bag materials for dust-free feeding.

10kg~50kg small bags can be equipped with grid structures for convenient feeding.

The workflow of the dust-free feeding station is as follows: the equipment is turned on, and the operator manually unpacks the small bags and transports the materials to the feeding grid for auxiliary feeding. The dusty airflow generated during feeding is sucked into the equipment box by the fan, and the dust is intercepted by the filter element. The clean air is discharged through the fan, and the filter element adopts pulse back blowing technology to regularly remove the dust on the surface of the filter element and maintain the negative pressure stability of the system. Thus achieving no dust flying during small bag feeding, ensuring the health of feeding personnel, and meeting local environmental production requirements. Below, customized silos, vibrating screens, and other materials can be used to meet different feeding needs.

Using stainless steel (such as SUS304/316L) or carbon steel material to form a sealed chamber to prevent dust leakage.

Equipped with an adjustable height console or bag clamp device, it is convenient for manual bag opening operations. Some models support sitting or standing posture operations.

An observation window is installed on the door for real-time monitoring of the feeding process, and an integrated access control interlocking system is also installed to automatically stop the fan operation when the door is opened, ensuring safety.

Filter element: Common filter elements include ultra-fine dust and synthetic fiber filter elements. Food grade filter elements can be made of various materials such as stainless steel filter elements to meet the cleanliness requirements of various industries.

Backblowing dust cleaning device: Pulse type automatic blowback system, regularly cleans the dust on the surface of the filter element, maintains filtration efficiency, and reduces manual maintenance.

Negative pressure fan: Provides stable negative pressure (usually achieved by vortex fans or Roots fans) to suck the dust generated by feeding into the filtration system.

Vibration screen: Equipped with a stainless steel mesh (such as 30-200 mesh) to intercept clumps or foreign objects, ensuring material quality.

Buffer hopper: temporarily stores materials, balances discharge speed, and prevents downstream equipment from overloading.

Mobile pulley: More flexible in usage scenarios.

Suction adapter: Used in conjunction with a vacuum feeder to complete material conveying.

PLC+touch screen: integrates one key start, parameter settings (such as blowback frequency, negative pressure value), status monitoring (filter pressure difference, fan operation), and fault alarm functions. More intelligent functions can be customized according to needs.

Emergency stop button: Quickly cut off power in case of emergency to prevent the accident from escalating. Anti static design: The grounding resistance of the equipment is ≤ 10 ⁶ Ω, and the filter element is made of anti-static material (such as metal coated polyester fiber) to prevent dust and static electricity from accumulating and causing explosions.

Explosion proof certification (optional): The equipment has CE certification and relevant explosion-proof certification certificates, suitable for flammable and explosive dust environments (such as flour, coal powder, etc.).

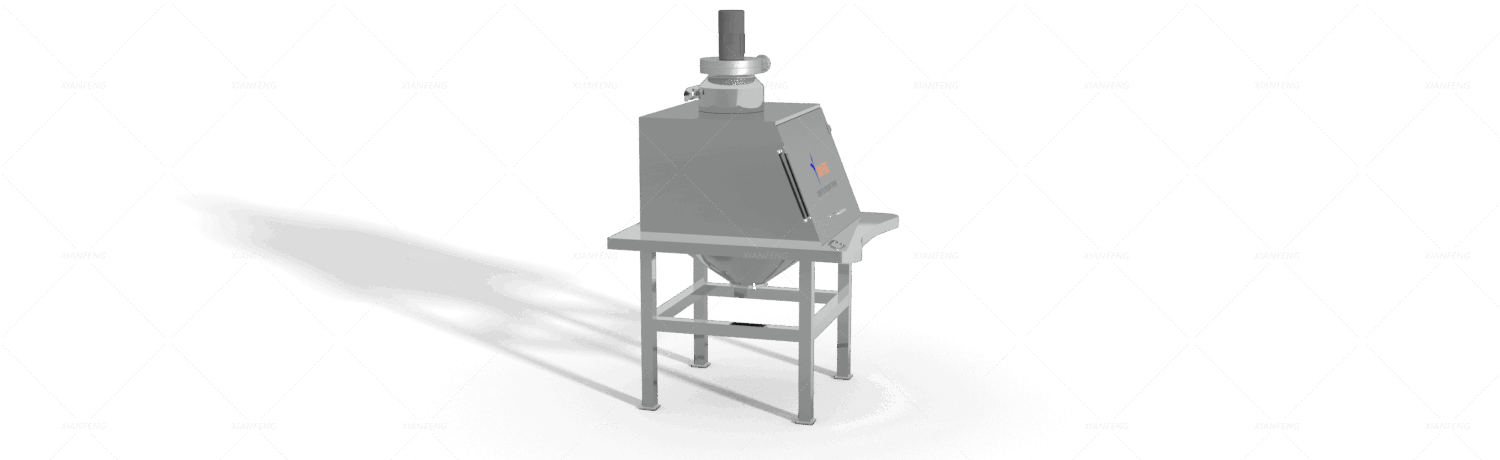

bag dumping station | Flour dust removal feeding

bag dump strtions | Additive dust-free feeding

Chemical powder dust-free feeding

| Model | Screening area(m²) | Motor power(kw) | Fan power(kw) | ||

| XFTL-600 | 0.22 | 0.25 | 1.1 | ||

| XFTL-800 | 0.4 | 0.25 | 1.5 | ||

| XFTL-1000 | 0.63 | 0.4 | 1.5 | ||

| XFTL-1200 | 0.95 | 0.4 | 2.2 | ||

When selecting, the following points should be considered:

Material characteristics: such as particle size, humidity, viscosity, bulk density, presence or absence of static electricity, flammability and explosiveness, etc.

Packaging specifications: weight range for handling bagged items (e.g. 10-50kg/bag) and unloading speed requirements.

Process requirements: Is it necessary to equip screening, conveying (positive/negative pressure), weighing and measuring devices.

Material and special requirements: Select suitable materials according to industry standards (such as GMP), and determine whether special designs such as explosion-proof, anti-corrosion, and anti-static are required

Space layout: The equipment size and overall height need to adapt to the on-site layout.

Automation level: Is it necessary to equip automatic cutters, bag pressing devices, waste bag recycling systems, etc. to improve the level of automation

There are three common types: 1. There is no design below the feeding port of the dust-free feeding station, only the dust removal feeding function. 2. On this basis, a buffer silo can be added and equipped with flange connections, discharge flip valves, suction adapters and other accessories to connect with various supporting equipment to meet the needs of different production scenarios. 3. Design a vertical sieve below the feeding port for flour materials to achieve dust-free feeding and remove impurities, suitable for various types of powders.

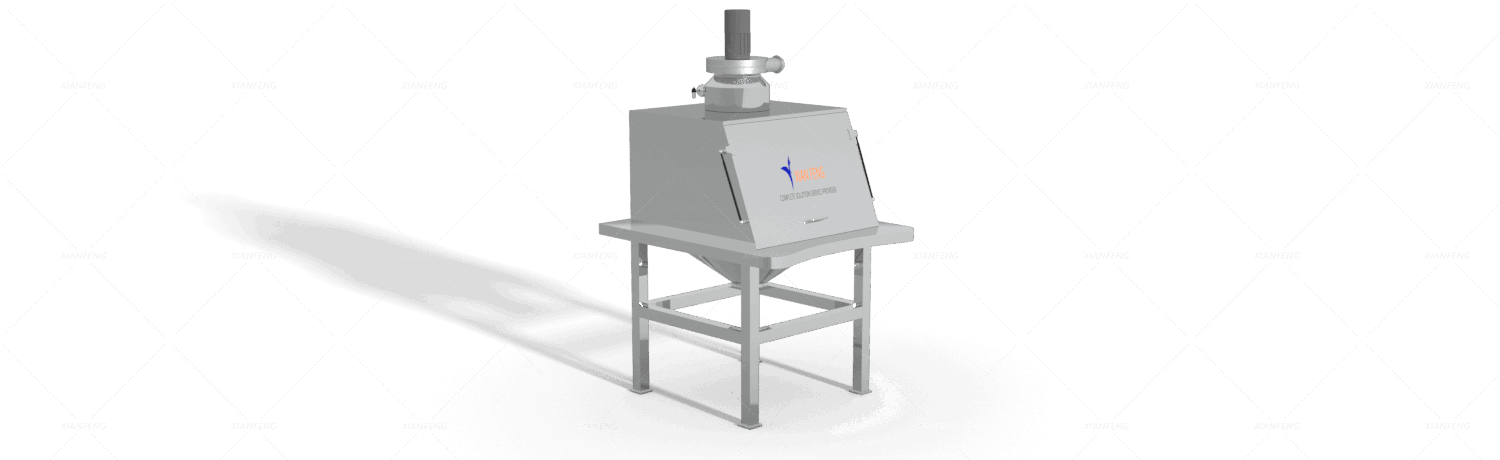

Yes, XIANFENG dust-free feeding station has CE, ISO related certification certificates and multiple national level technical patents. Each equipment undergoes strict quality inspection before shipment and can be customized according to your actual needs. You can directly contact us to discuss more details.

Our core advantage is that the price is 30% -40% lower for the same quality, and the quality is even better for the same price. All of our equipment core components are made of well-known imported brands, so you don't have to worry about equipment quality and stability. To provide you with more cost-effective equipment and save your costs.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.